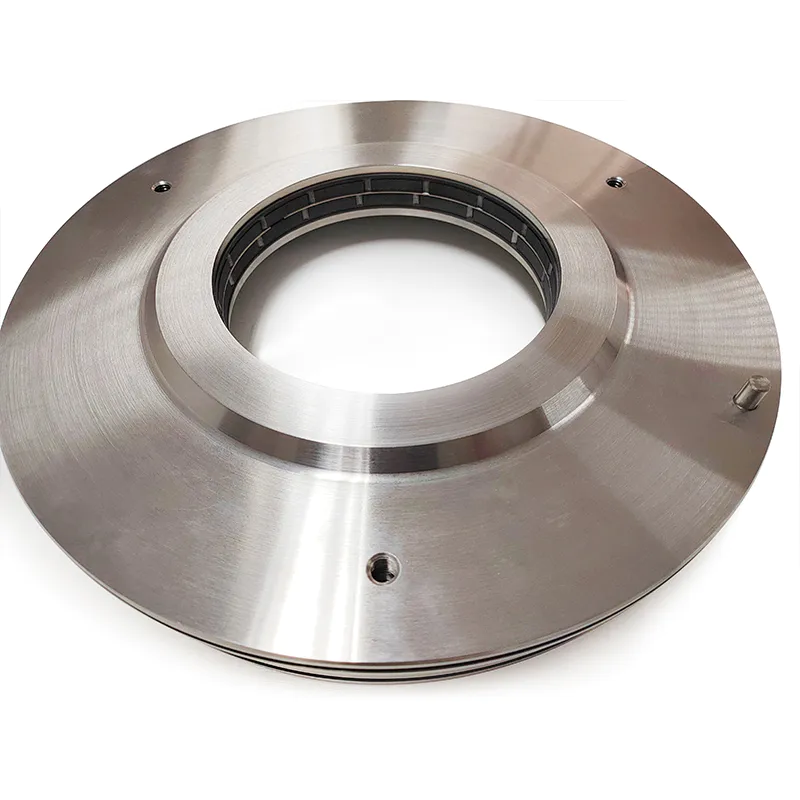

Dry Gas Seal

The difference between metal bellows mechanical seal and ordinary mechanical seal

by:Lepu Seal

2022-09-03

Bellows type mechanical seals have a wide range of applications, from low temperature to high temperature, from neutral media to corrosive media, from low speed to high speed, and from ordinary to harsh working conditions. Bellows include rubber bellows and serpentine sleeves, plastic bellows and metal bellows. Rubber bellows and serpentine sleeves are used for low-load mechanical seals as auxiliary seals; plastic bellows are used for mechanical seals in strong corrosive media as auxiliary seals; metal bellows are used for mechanical seals of high temperature, high pressure and low temperature media, which can be used as auxiliary seals and Can be used as elastic element. The welded metal bellows mechanical seal has good floatability and random compensation, which can compensate for the leakage of the seal ring due to wear, axial movement and vibration. The welded metal bellows itself acts as both an elastic element and a seal. There is no auxiliary sealing ring in the middle of the metal bellows mechanical seal, which reduces a leakage point; at the same time, the frictional resistance of the compensation mechanism is reduced; in the petrochemical industry, welded bellows The use temperature of the seal is not limited by the auxiliary seal ring; for the PTFE bellows seal, it can be used in corrosive media. The disadvantage is that some bellows have less elastic force and need to add auxiliary springs. Welded metal bellows is made of staggered and tightly welded inner and outer diameters of each wave plate, so there is no need to consider the direction of rotation when it is used as a static or rotary type. Welded metal bellows can be made of precipitation hardened stainless steel, high-temperature nickel-based materials and chromium-nickel corrosion-resistant materials, so welded metal bellows can be used in a wide range of temperature (-11℃-426℃), and various Acid, alkali, salt medium. Choose different thicknesses and layers of the wave plate so that it can withstand a pressure of up to about 7MPa in the pump. The design of the welded metal bellows mechanical seal is generally balanced, so its bearing pressure has little effect on the specific pressure of the end face. The welded metal bellows mechanical seal is not only suitable for non-hydrocarbon media, but also for flashing hydrocarbon media. Compared with ordinary mechanical seals, its service life has also been greatly improved, so it has a higher performance-price ratio.

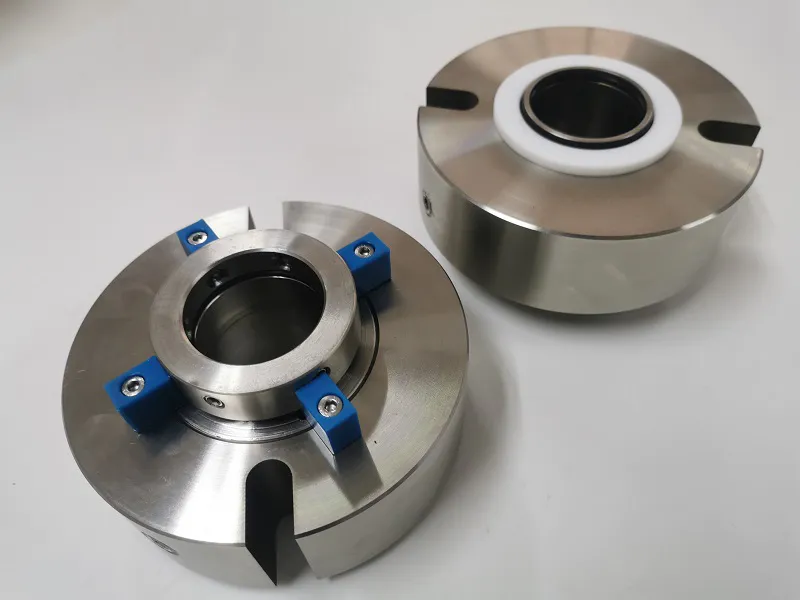

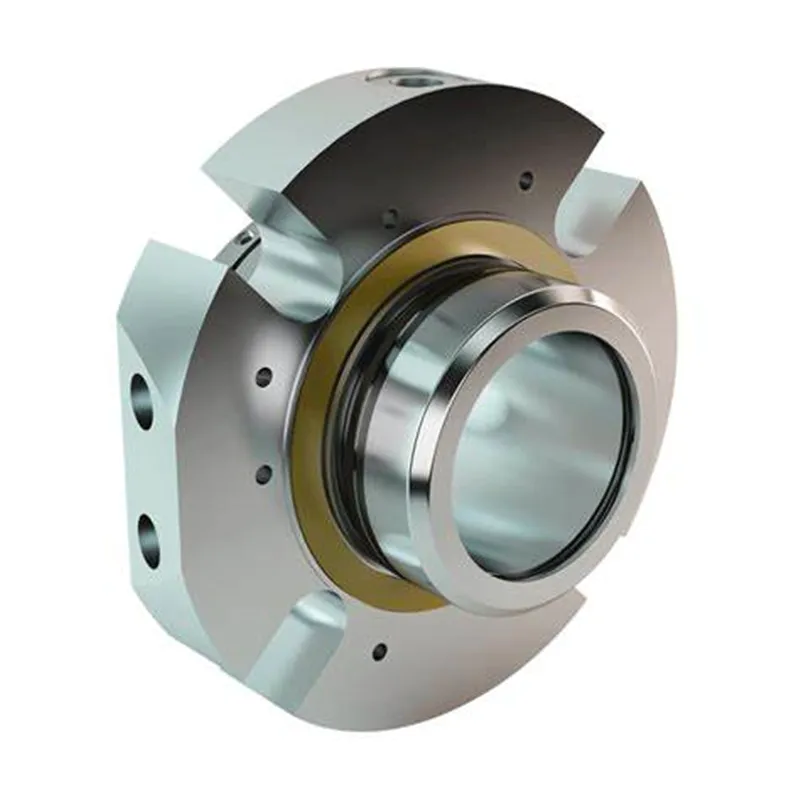

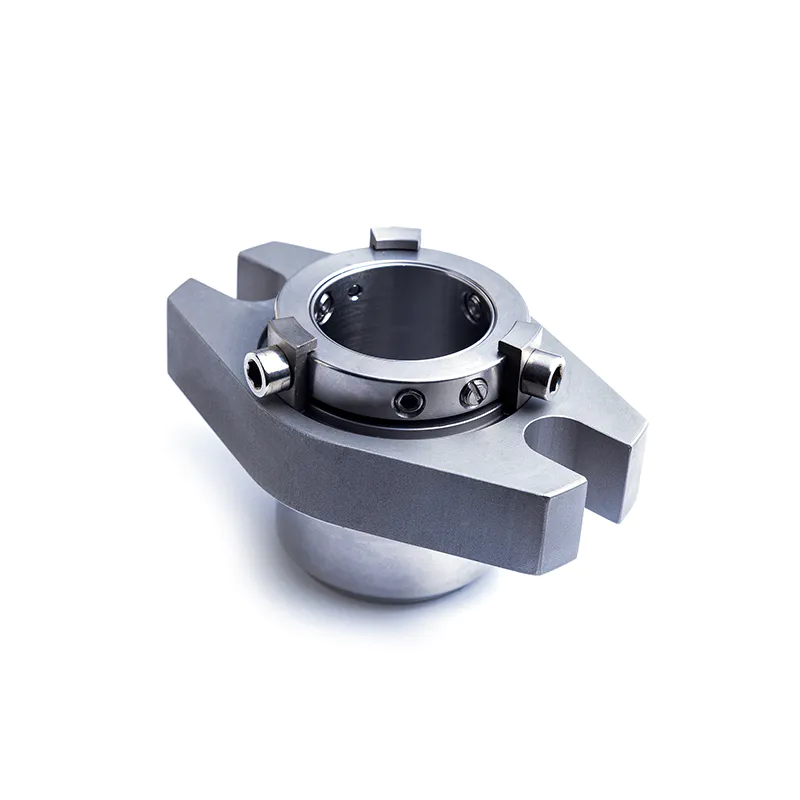

Metal bellows mechanical seal features:

Bellows is a sealing element that integrates elastic elements, auxiliary seals and torque transmission mechanisms (ordinary seals do not have this kinetic energy), and the torque mode is unique to bellows mechanical seals. The specific pressure of the end face is uniform, and it has the characteristics of high temperature resistance and good followability. The moving ring has no auxiliary sealing ring, thus reducing a leakage point and reducing frictional resistance of the moving ring.

Commonly used bellows are pressed and welded. Pressed bellows are made on a press or by hydraulic pressure molding by stretching and forming thin-walled tubes; welded bellows are made by welding the inner and outer circles of film sheets (commonly used).

Advantages of metal bellows mechanical seal:

High precision: The welded bellows acts as a spring, and is a combination of many springs, so it solves the problem of ordinary springs deformed by centrifugal force, adapts to high rotation, and makes the sealing surface evenly pressed, which is conducive to preventing leakage.

Vibration resistance and flexibility: The bellows has high flexibility and has a very good absorption effect on vibration, so it has a very strong adaptability to radial runout, axial clearance, vibration and swing, and can effectively prevent leakage.

Simple structure: Unlike other ordinary mechanical seals, which are composed of many parts, it has the characteristics of integrated assembly, simple structure and easy assembly.

It can adapt to various temperature conditions: the thermal expansion coefficient of the welded bellows is small, it can be used at low temperature or high temperature, and there is no O-ring, it can get rid of the limitation of temperature, and the design is relatively free.

Applicable to high pressure conditions: Since the bellows itself can play a balancing role, the corresponding sealing area can be designed to offset the fluid pressure and reduce the friction of the sealing surface, thereby reducing heat generation and wear, and can be used in high pressure conditions.

No shaft sleeve to effectively protect the pump: the welded bellows mechanical seal does not need to install the shaft sleeve because there is no O-ring, so the wear of the shaft or the shaft sleeve caused by the abrasion of the O-ring will not occur, thus protecting the pump from running. effect

Applicable to corrosive fluids: as long as the welded bellows is made of materials such as Hastelloy 276 with high corrosion resistance, the corrosion problem of springs and O-rings can also be avoided, and sealing can be effectively achieved.

No hanging leakage: In ordinary push-ring mechanical seals, the leaked trace fluid will solidify and deposit in the presence of air, preventing the advancement of the O-ring moving ring, and weakening or disappearing the sealing force on the end face of the seal, resulting in leakage. On the contrary, the welded bellows mechanical seal does not have an O-ring, even if it is cured, the influence is not large, and it can still rotate stably, so it has a long service life.

With threaded pumping effect: The bellows itself has a threaded pumping effect, which can effectively deal with fluids containing solid particles and facilitate flushing.

Custom message