Dry Gas Seal

The difference and selection of water pump packing seal and kettle mechanical seal

by:Lepu Seal

2022-07-27

The shaft seal is a sealing device set up to prevent leakage between the pump shaft and the casing. Commonly used shaft seals are packing seals, mechanical seals and dynamic seals.

The shaft seal of the reciprocating pump is usually a packing seal. When the medium is not allowed to leak, a diaphragm type reciprocating pump can be used. The shaft seals of rotary pumps (including vane pumps, rotor pumps, etc.) mainly include packing seals, mechanical seals and dynamic seals.

1. Packing seal

The packing seal has simple structure, low price and convenient maintenance, but has large leakage and large power loss. Therefore, packing seals are used to transport general media, such as water: generally not suitable for petroleum and chemical media, especially in precious, explosive and toxic media.

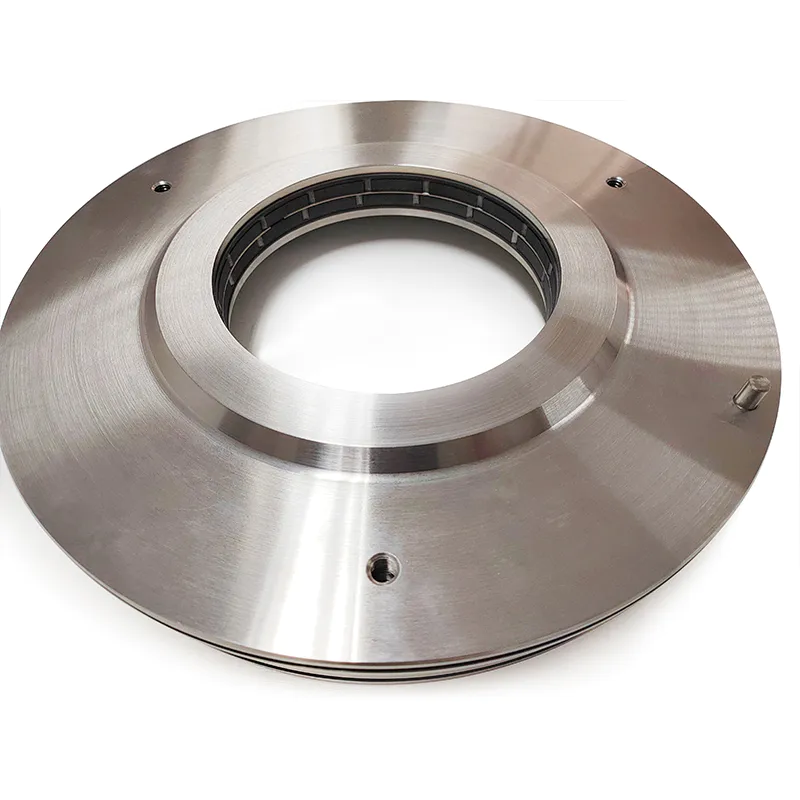

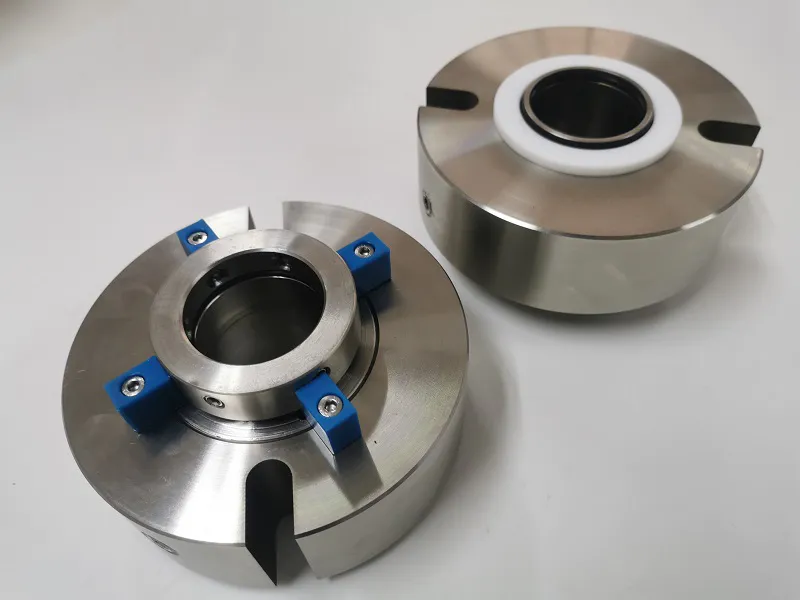

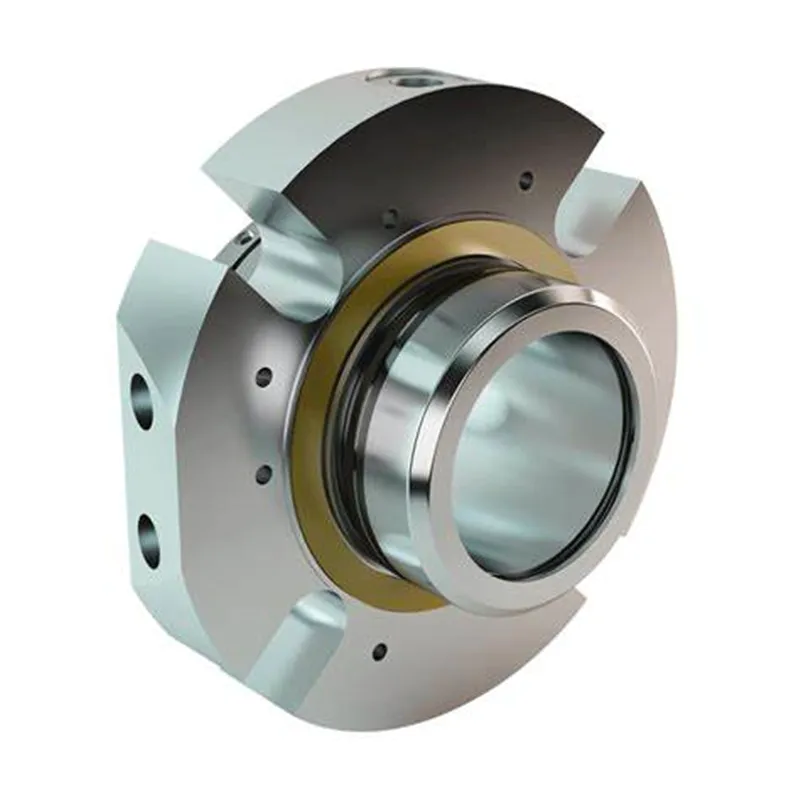

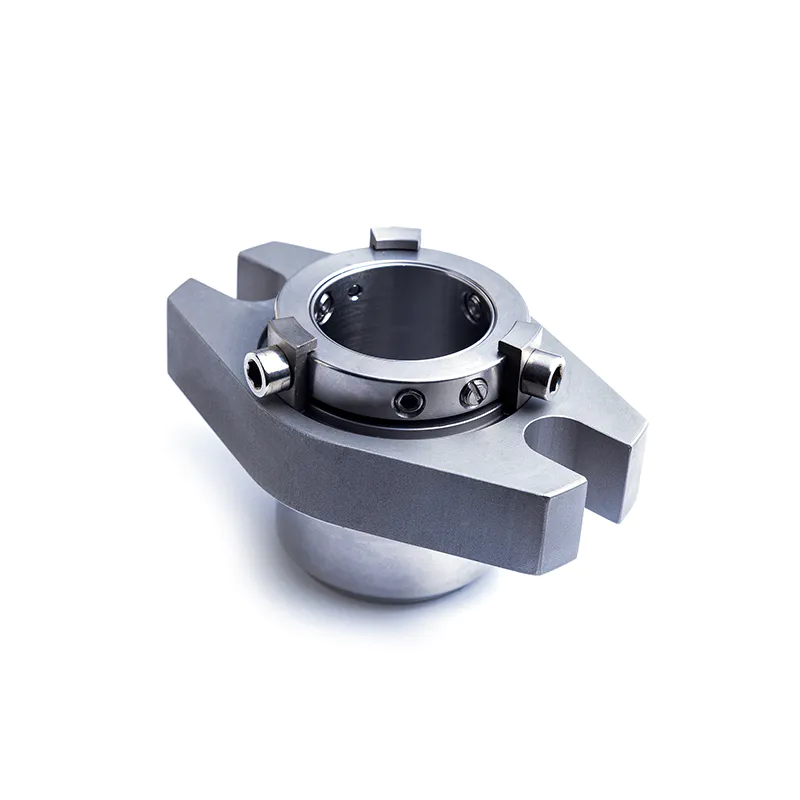

2. Mechanical seal

Mechanical seals (also known as end face seals) have good sealing effect, small leakage and long service life, but are expensive, and require higher processing, installation and maintenance than general seals. The mechanical seal is suitable for conveying and petroleum and chemical media, and can be used for various viscosities, strong corrosive media containing particles. The logo of the American Petroleum Institute stipulates that unless specified by the user, a cartridge mechanical seal should be equipped.

3. Dynamic seal

Dynamic seals can be divided into two types: back vane seals and auxiliary impeller seals. When the pump is working, the centrifugal force of the back vane (or auxiliary impeller) causes the medium pressure at the shaft seal to drop to the normal pressure or negative pressure state, so that the pump does not leak during use. When the centrifugal force disappears when parking, the sealing effect of the back blade (or auxiliary impeller) fails, and the sealing effect is achieved by the parking sealing device.

Packing seals are often used in the parking seal device matched with the back vane (or auxiliary impeller). There are two types of packing seals: ordinary type and mechanical elastic type. The ordinary packing seal is similar to the general packing seal pump, and requires a slight positive pressure at the shaft seal to avoid dry friction of the packing. The mechanical elastic packing stop seal adopts counterweight, so that the packing is loosened when the pump is running, and the packing is compressed when the pump is stopped.

In order to ensure the life of the parking seal device and reduce the leakage amount, the inlet pressure of the pump should be limited for the use of dynamic seal pumps, namely:

In the formula, Ps-pump inlet pressure, MPa:

Pd-pump inlet pressure, MPa

Reliable power tightness, cheap price, easy maintenance, suitable for conveying medium containing more solid particles such as ore slurry and slurry pump in phosphoric acid industry. The disadvantage is that the power loss is larger than that of the mechanical seal, and the life of the parking seal is shorter.

The shaft seal is a sealing device set up to prevent leakage between the pump shaft and the casing. Commonly used shaft seal types are packing seals, mechanical seals and dynamic seals. The shaft seal of a reciprocating pump is usually a packing seal. When the medium is not allowed to leak, the diaphragm type reciprocating pump can be used. The shaft seals of rotary pumps (including vane pumps, rotor pumps, etc.) mainly include packing seals, mechanical seals and dynamic seals

Custom message