Preventing Premature Failures: Common Mistakes with John Crane Seals

Preventing Premature Failures: Common Mistakes with John Crane Seals

Understanding the Importance of Proper Seal Selection

Installation Errors: A Potential Cause for Premature Failures

Maintenance and Monitoring: Key Steps to Enhance Seal Longevity

Overcoming Operational Challenges to Avoid Seal Failures

The Role of Training and Education in Preventing Premature Seal Failures

Understanding the Importance of Proper Seal Selection

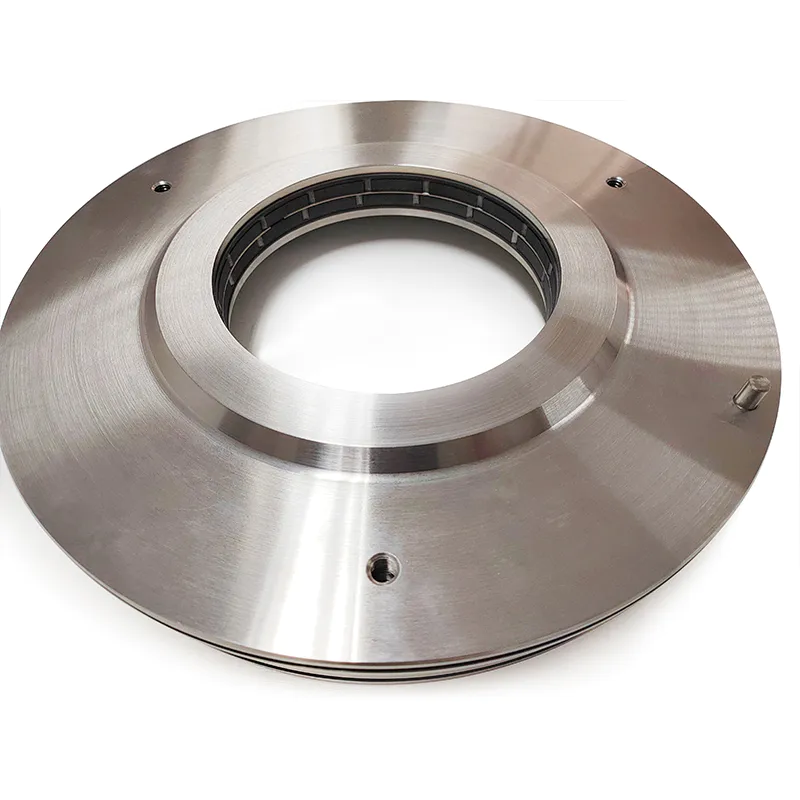

Selecting the right seal is crucial for ensuring optimal performance and preventing premature failures in industrial applications. John Crane, a leading manufacturer of mechanical seals, offers a wide range of options tailored to various operating conditions. However, failure to choose the appropriate seal for a specific application can lead to significant drawbacks.

When selecting a mechanical seal, it is essential to consider factors such as operating temperature, pressure, speed, and the nature of the fluid being sealed. Neglecting these parameters can result in inadequate sealing, increased friction, excessive wear, and ultimately, premature failure of the seal.

Installation Errors: A Potential Cause for Premature Failures

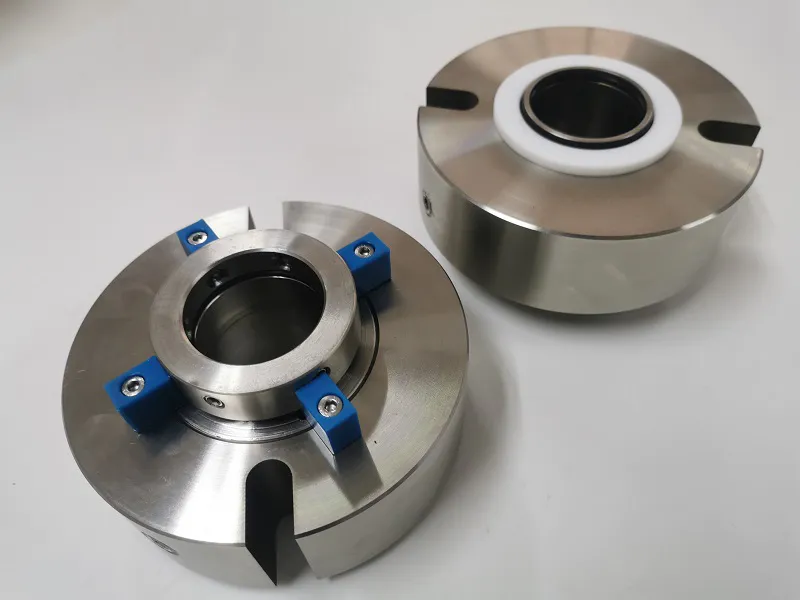

Even with the right seal, improper installation can compromise its effectiveness and lifespan. One common installation mistake is improper torque application during the tightening process. Insufficient or excessive torque can lead to leaks or damage to the seal faces. It is crucial to follow the manufacturer's guidelines and specifications to ensure proper torque values for each type of seal.

Another common installation error is misalignment, where the seal faces are not perfectly aligned with each other or the shaft. Misalignment can result in uneven wear, weakening of the seal, and ultimately, failure. Proper alignment techniques, such as laser alignment tools, should be employed to avoid this issue.

Maintenance and Monitoring: Key Steps to Enhance Seal Longevity

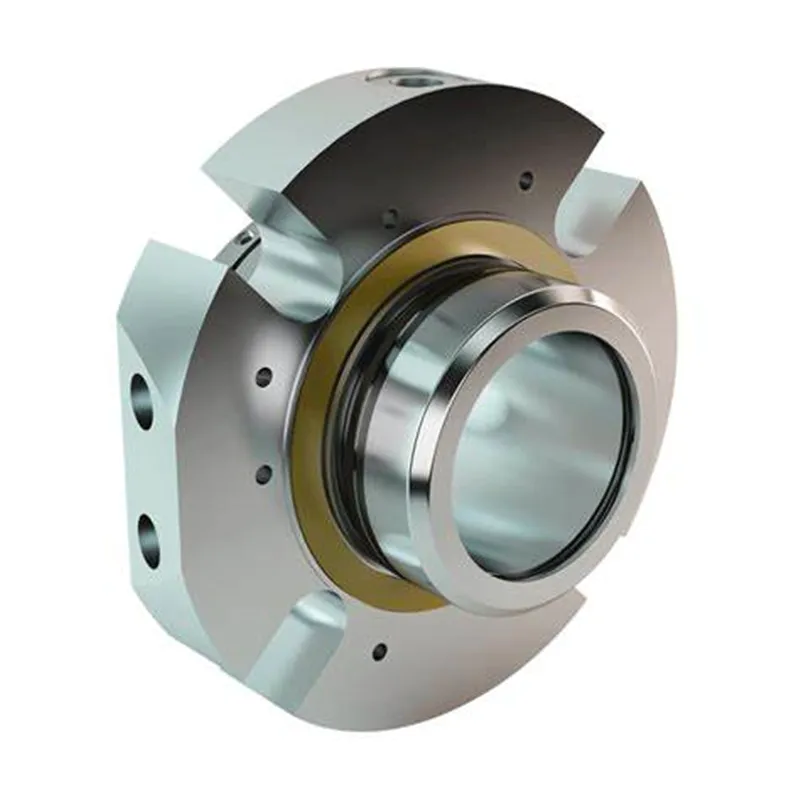

Regular maintenance and monitoring play a vital role in preventing premature seal failures. Effective maintenance practices include inspecting seals for wear, adjusting operating conditions, and replacing components when necessary. Implementing a proactive maintenance strategy can significantly extend the life of John Crane seals.

Monitoring techniques like vibration analysis and thermal imaging can help detect early warning signs of potential issues. Unusual vibrations or temperature variations can indicate misalignment, worn bearings, or other factors that may impact the longevity of the seal. Timely identification and addressing of these issues can prevent costly breakdowns and unscheduled downtime.

Overcoming Operational Challenges to Avoid Seal Failures

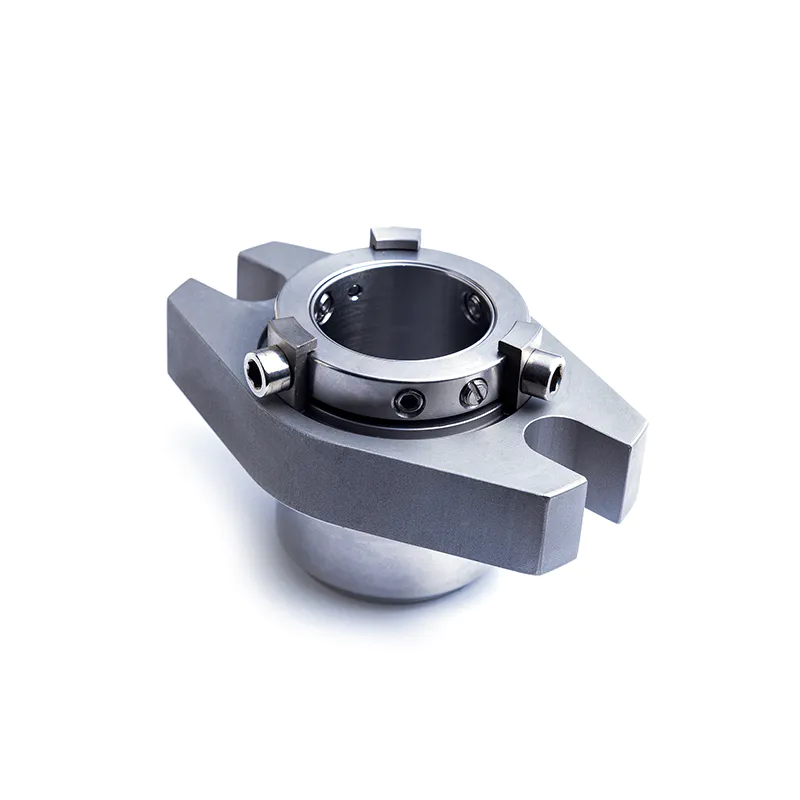

Operating conditions often present challenges that can lead to premature seal failures. Certain applications may involve abrasive fluids, high pressures, or extreme temperature variations. In such cases, it is crucial to select seals specifically designed to withstand these challenges.

Abrasive particles in the fluid can cause wear and damage to the seal faces. Using seal materials with higher resistance to abrasion can mitigate this issue. Similarly, selecting seals with appropriate temperature and pressure ratings for a given application will ensure optimal performance and prevent premature failures.

The Role of Training and Education in Preventing Premature Seal Failures

Proper training and education are instrumental in ensuring that those responsible for seal installation and maintenance understand the best practices and common pitfalls. Lack of knowledge and expertise can lead to costly mistakes and unnecessary seal failures.

John Crane provides training programs to educate technicians and engineers on seal selection, installation, and maintenance. These programs equip professionals with the necessary knowledge and skills to make informed decisions and carry out effective maintenance routines.

In conclusion, preventing premature failures of John Crane seals necessitates a comprehensive understanding of the importance of proper seal selection, avoiding installation errors, implementing proactive maintenance practices, overcoming operational challenges, and providing the necessary training and education. By incorporating these practices, industries can enhance the longevity and performance of their mechanical seals, ultimately reducing downtime and optimizing processes.