How to Select the Right Mechanical Seal Material for Your Process Fluids

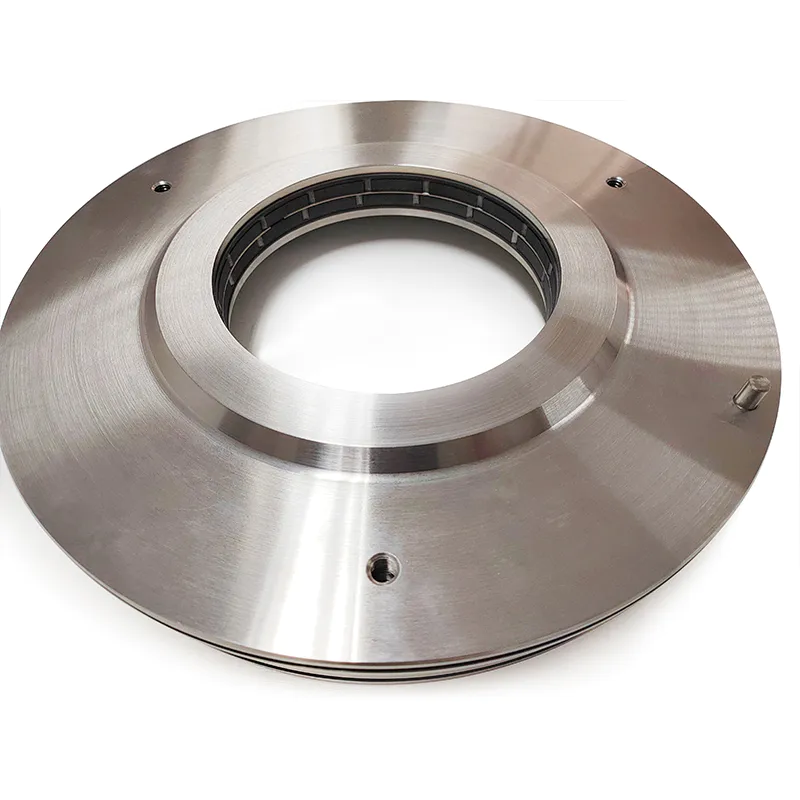

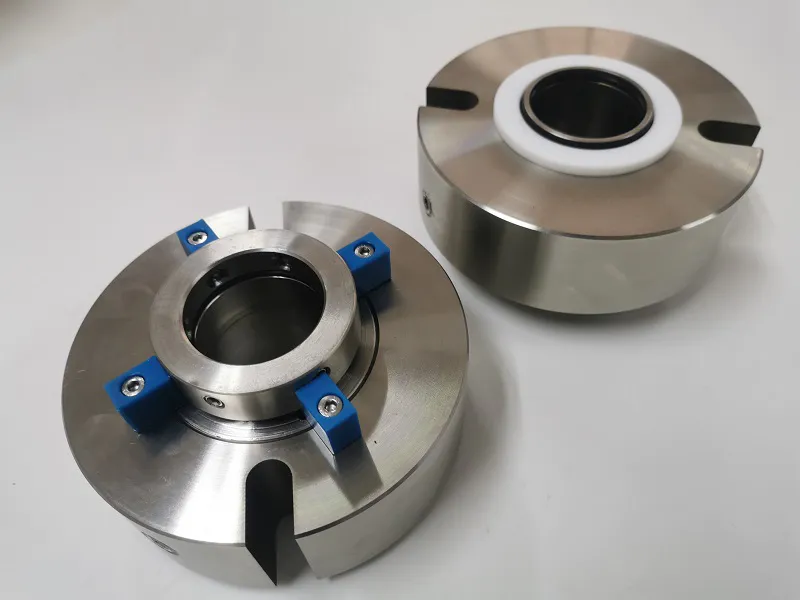

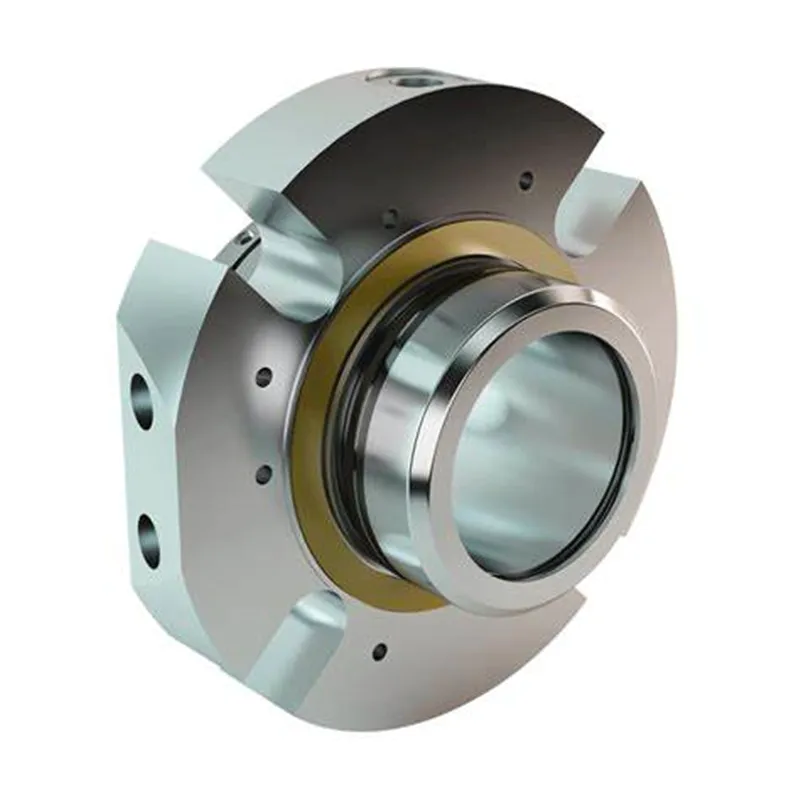

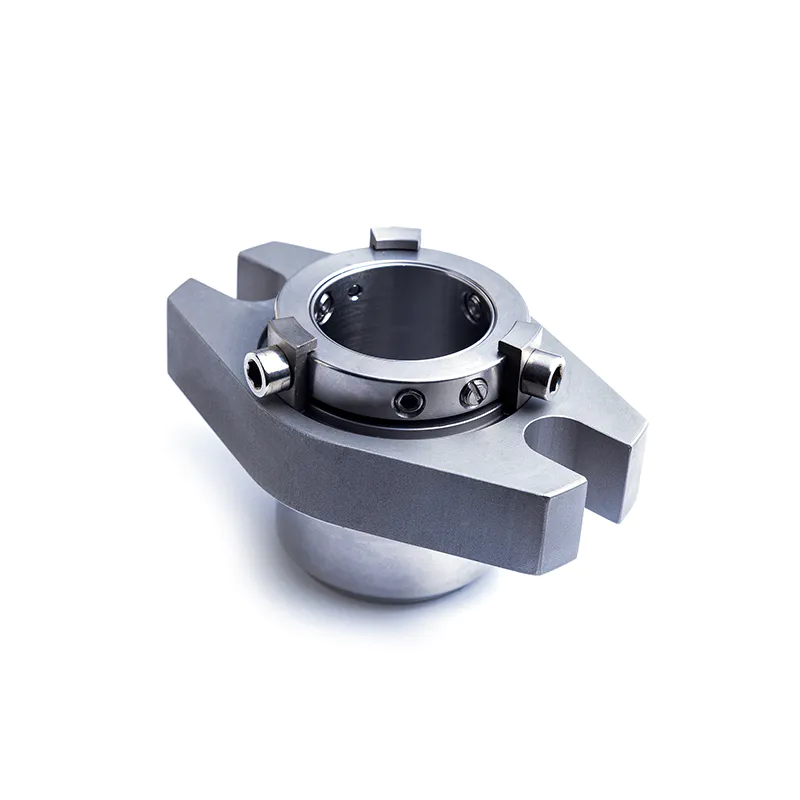

Mechanical seals are crucial components of pumps, mixers, and other equipment that handle fluids in industrial processes. These seals prevent the fluid from leaking into the environment and causing contamination, or damaging the equipment. Selecting the right mechanical seal material is essential to ensure that the seal can withstand the chemical and physical properties of the process fluid, as well as the temperature, pressure, and other operating conditions. In this article, we will discuss how to choose the right mechanical seal material for your process fluids.

Understanding Mechanical Seal Materials

Mechanical seals are made of various materials that feature different chemical and physical properties. Some of the most common materials used in mechanical seal manufacturing include:

1. Carbon: Carbon is a versatile material that is widely used in mechanical seals. It has a high thermal conductivity, excellent mechanical strength, and chemical resistance. Carbon-based mechanical seals are ideal for handling high-speed fluids, high-temperature fluids, and abrasive fluids. They are also suitable for various applications, including petrochemicals, oil and gas, and pulp and paper.

2. Ceramic: Ceramic is a durable material that offers high resistance to wear and corrosion. It is ideal for use in harsh environments where the process fluid is aggressive or corrosive. Ceramic mechanical seals are commonly used in chemical processing, pharmaceuticals, and semiconductors.

3. Tungsten carbide: Tungsten carbide is a hard material that is suitable for handling abrasive fluids and high-pressure fluids. It offers excellent wear and corrosion resistance, making it ideal for use in the oil and gas, mining, and pulp and paper industries.

4. Stainless steel: Stainless steel is a popular material for mechanical seals as it offers high resistance to corrosion, wear, and oxidation. Stainless steel mechanical seals are suitable for handling a wide range of fluids, including water, oil, and chemicals, and they are commonly used in food and beverage, pharmaceuticals, and wastewater treatment.

Factors to Consider When Selecting Mechanical Seal Materials

There are several factors to consider when selecting the right mechanical seal material for your process fluids, including:

1. Temperature: The mechanical seal material must be able to withstand the temperature of the process fluid. For example, carbon-based mechanical seals can withstand temperatures of up to 800°C, making them ideal for high-temperature applications, while ceramic seals can withstand temperatures of up to 1000°C.

2. Pressure: Mechanical seals must be able to withstand the pressure of the process fluid. The pressure rating of the seal will depend on the material used, the design of the seal, and the application.

3. Chemical compatibility: It is important to choose a mechanical seal material that is compatible with the process fluid. For example, ceramic seals are ideal for handling aggressive chemicals, while stainless steel is suitable for handling mild chemicals.

4. Abrasive fluid: If the process fluid is abrasive, it is essential to choose a material that can withstand the wear and tear. Tungsten carbide is an ideal material for handling abrasive fluids.

5. Hygienic requirements: If the process fluid needs to meet hygienic requirements, it is essential to choose a mechanical seal material that is easy to sanitize and clean. Stainless steel is an ideal material for hygienic environments.

Choosing the Right Mechanical Seal Material

When choosing the right mechanical seal material for your process fluids, it is essential to consider the factors mentioned above. You should also consult with a mechanical seal manufacturer or supplier to determine the best material for your specific application. Here are some steps to follow when selecting the right mechanical seal material:

Step 1: Determine the operating conditions: Gather information about the temperature, pressure, and chemical properties of the process fluid. This information will help determine the type of material that can withstand the conditions.

Step 2: Determine the application: Consider the type of equipment that the mechanical seal will be used for and the type of fluid it will handle. This information will help determine the type of seal design and material that will be suitable for the application.

Step 3: Consult with a mechanical seal supplier: Contact a mechanical seal manufacturer or supplier to discuss your application and the materials that are available. The supplier can offer recommendations based on their experience and expertise.

Step 4: Test the material: Once you have selected a material, it is important to test it in your application to ensure that it can withstand the operating conditions.

Conclusion

Mechanical seals are critical components of equipment handling fluids in industrial processes. Choosing the right mechanical seal material is crucial to ensure that the seal can withstand the chemical and physical properties of the process fluid, as well as the temperature, pressure, and other operating conditions. By considering the factors mentioned above and consulting with a mechanical seal supplier, you can ensure that you select the right material for your specific application. With the right material, you can maximize equipment performance and minimize downtime and maintenance costs.