How to Choose the Right Alfa Laval Mechanical Seal for Your Application

.

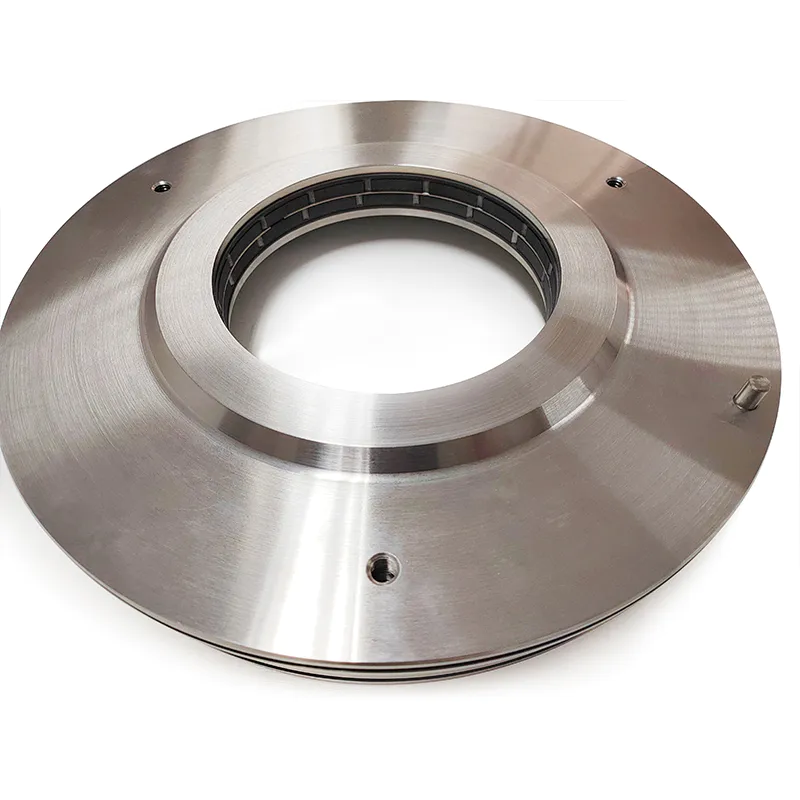

Alfa Laval Mechanical Seals are used in a wide range of applications to prevent fluid leakage between two surfaces. These seals are used in various industries, from oil and gas to food and beverage manufacturing. With so many types of mechanical seals available in the market, choosing the right one can be challenging. In this article, we will guide you through the key factors to consider when selecting an Alfa Laval Mechanical Seal that is right for your application.

1. Understand Your Machinery

One of the critical factors to consider when selecting a mechanical seal is understanding your machinery. Different types of machinery have different sealing requirements. Before choosing a seal, you need to know what the machine operates, the type of fluid it contains, and its operating conditions. This information can help you choose the right mechanical seal that can withstand the pressure, temperature, and other conditions specific to your application.

2. Know the Materials

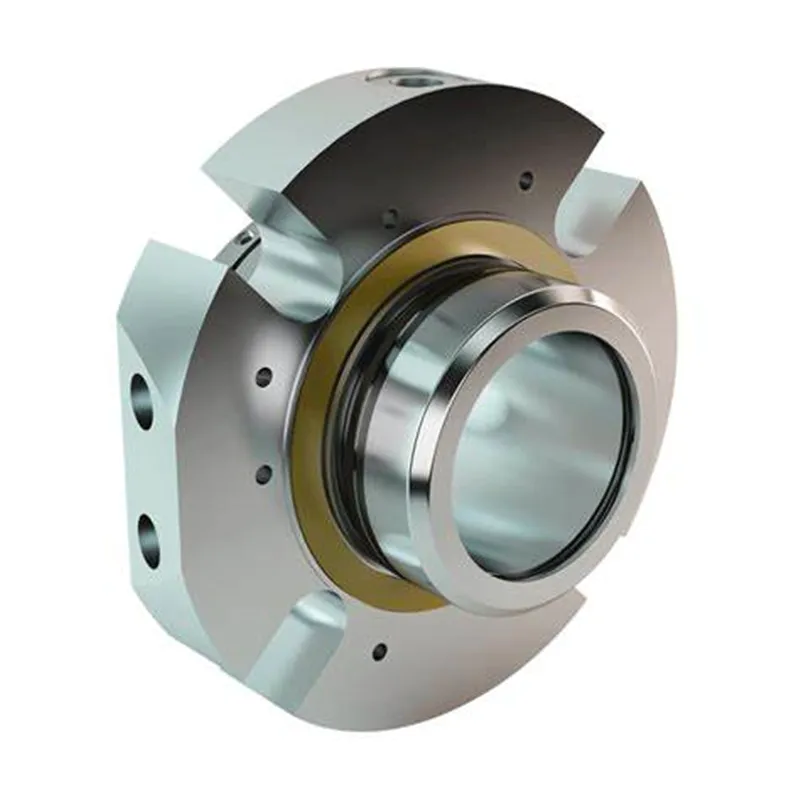

Alfa Laval Mechanical Seals may come in different materials, including rubber, carbon, and ceramic. The material you choose depends on your application's specific needs and requirements. For example, if your application involves high temperatures and pressures, a graphite or carbon seal type may be the best option. However, if the fluid you are sealing is abrasive or corrosive, a ceramic seal may be more suitable.

3. Understand the Type of Seal

There are different types of mechanical seals that you can choose from, including single, double, and tandem seals. Single seals are the most common type and consist of a single rotating element that seals against a stationary element. These types of seals are suitable for most applications, including low to moderate pressures.

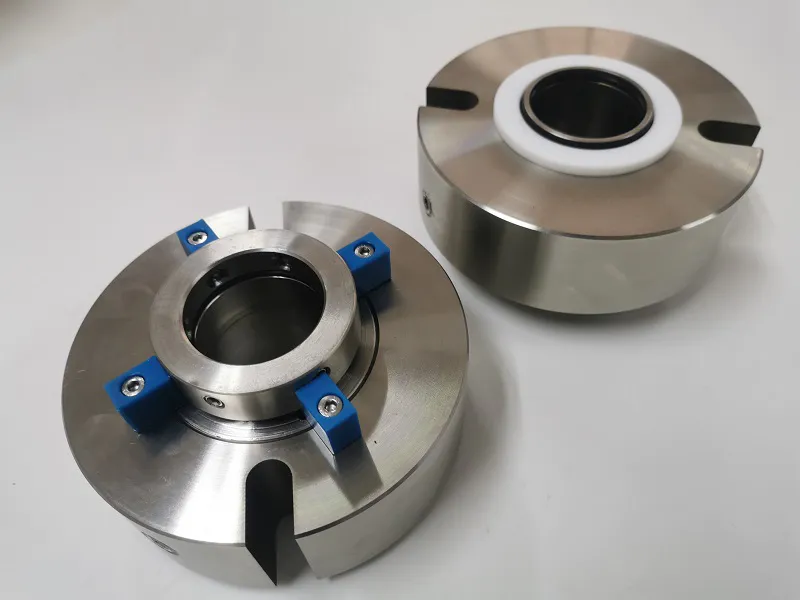

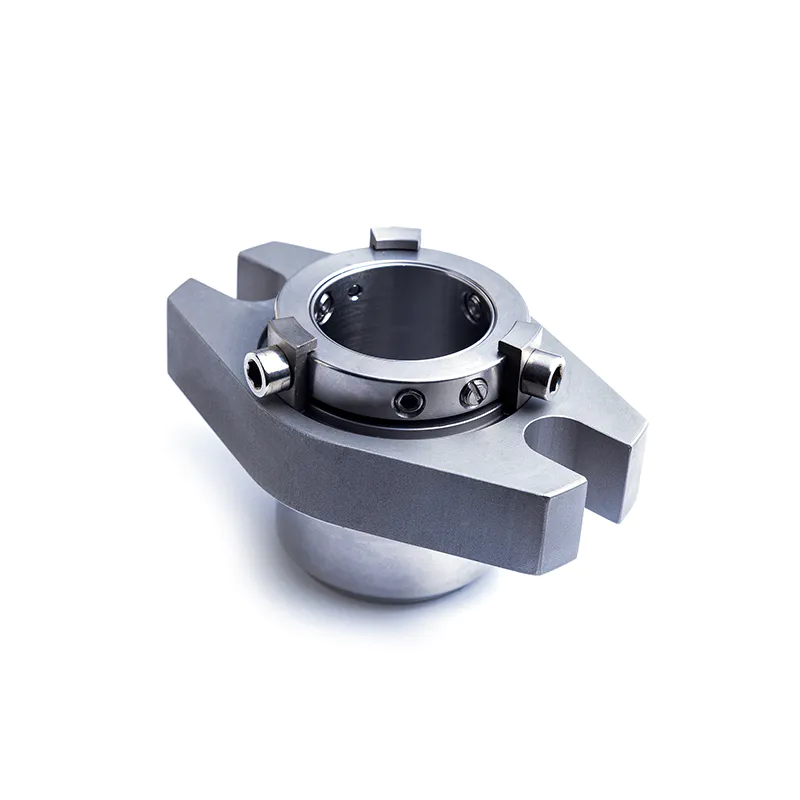

On the other hand, double seals consist of two sets of primary seals and a barrier fluid system that provides an additional layer of protection against leakages. This type of seal is ideal for applications where high-pressure and high-temperature conditions are involved. Tandem seals, on the other hand, are often used in pumping equipment for wastewater treatment and other applications that require high-pressure seals.

4. Consider the Installation Technique

When choosing an Alfa Laval Mechanical Seal, you need to consider the installation technique. There are two primary installation techniques that you can use- direct and semi-cartridge. Direct installation involves mounting the seal directly onto the shaft. This installation technique is ideal for smaller pumps and engines.

On the other hand, semi-cartridge installation involves mounting the stationary seal onto the pump housing. This method offers more flexibility and is suitable for larger and more complex pumps. Both installation techniques are effective, but the choice you make should depend on your specific needs and requirements.

5. Choose the Right Seal Supplier

Choosing a reliable mechanical seal supplier is critical to ensuring you get the right product for your application. Consider factors such as the supplier's reputation, the range of products they offer, their customer service, and their willingness to provide technical support.

Conclusion

In conclusion, selecting the right Alfa Laval Mechanical Seal for your application requires careful consideration of various factors, including understanding your machinery, the type of materials, the type of seal, the installation technique, and choosing a reliable mechanical seal supplier. At Sealcon, we are a trusted supplier of high-quality mechanical seals. Contact us today to discuss your sealing needs, and we'll help you choose the right mechanical seal for your application.