Cartridge Mechanical Seal

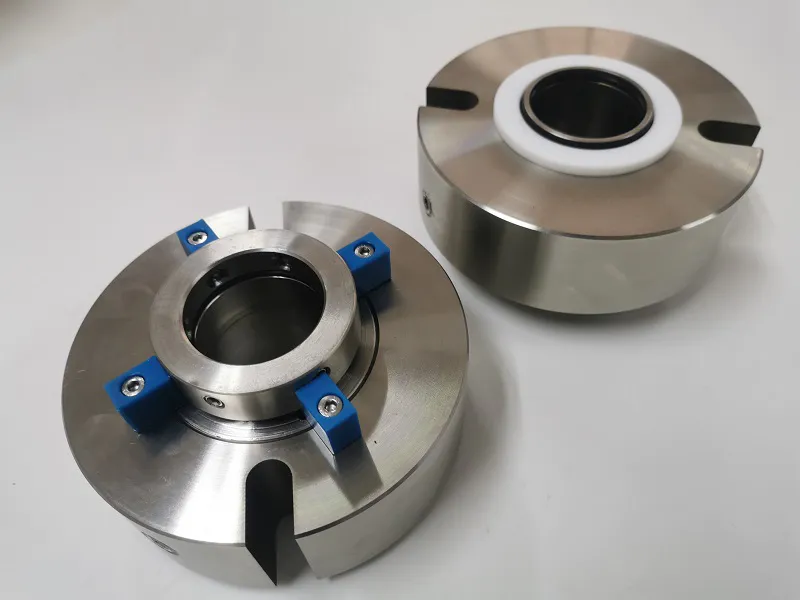

Flex-A-Seal's corrosion-resistant welded metallic bellows cartridge seal was specifically designed to suit Fybroc® pumps mostly found within the aquariums and zoos worldwide without modification. A simple, proven and rugged design with dependability that has made it a favourite choice of maintenance personnel to seal ANSI chemical pumps.

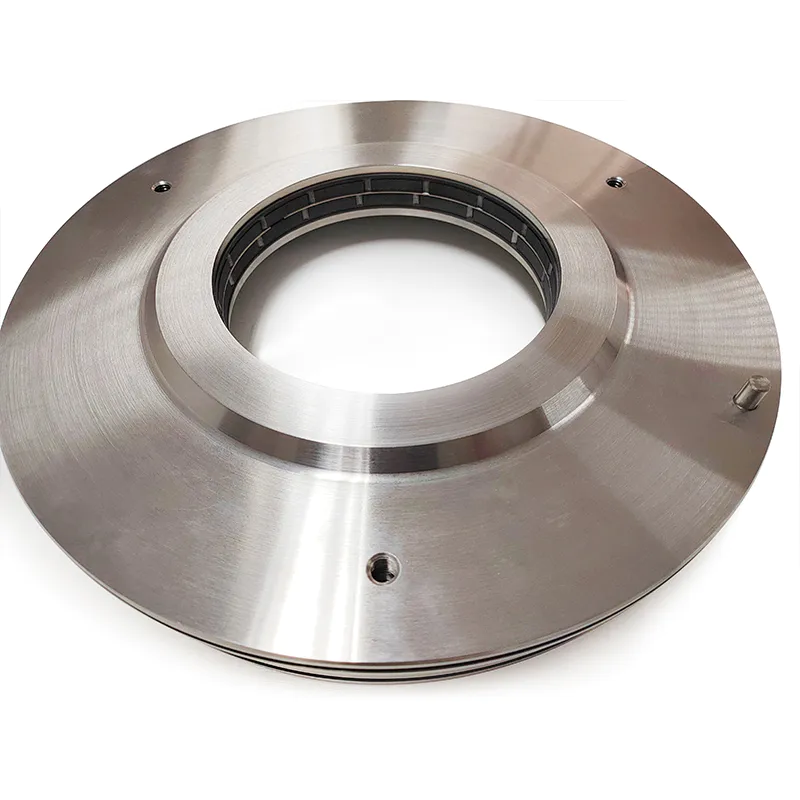

The bushing additionally offers effective management of quench water piped via the gland. The seal is rated for seven hundred psig , temperature to 550° F (290° C) and a surface pace of four,000 ft/min (20 m/sec).

End users can profit from dramatic seal maintenance cost reductions on two levels. First, an affordable excessive technology cartridge seal for conversion of packed stuffing boxes with out modification, non-cartridge seals and old excessive cost / low know-how design cartridge seals. Second, using design features with benefits that provide maximized performance in ninety% of all seal applications with ensuing long term seal maintenance control and reduction.

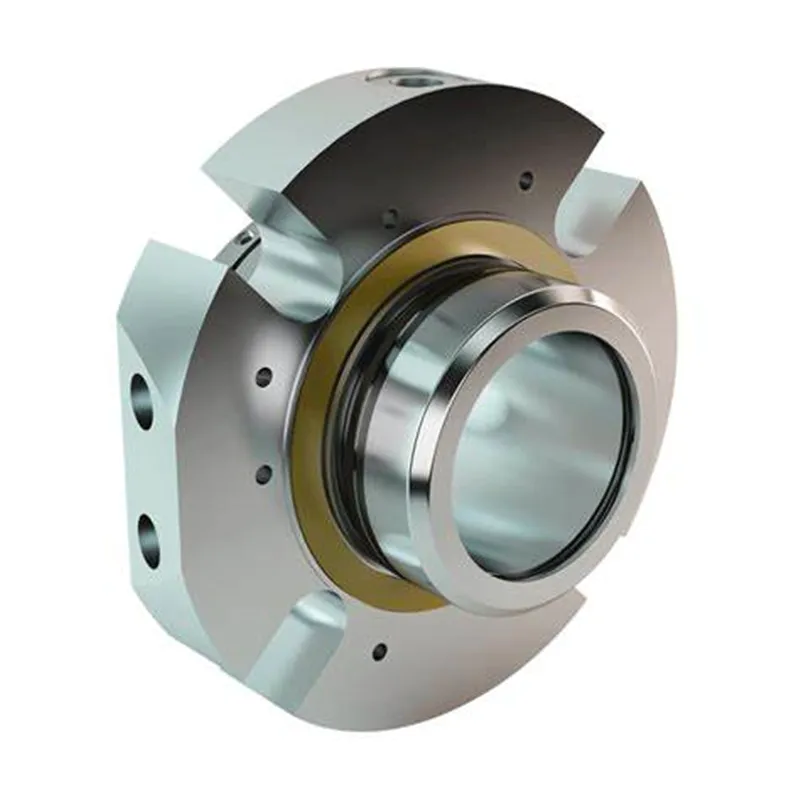

The best answer for seal users is mechanical seals lubricated immediately by the process fluid. UNCD coated silicon carbide as a seal face materials permits Flowserve to supply improved reliability in poor lubricating fluids with out extra controls. The amount of pressure exerted at a mechanical seal’s faces has a big impact on its efficiency.

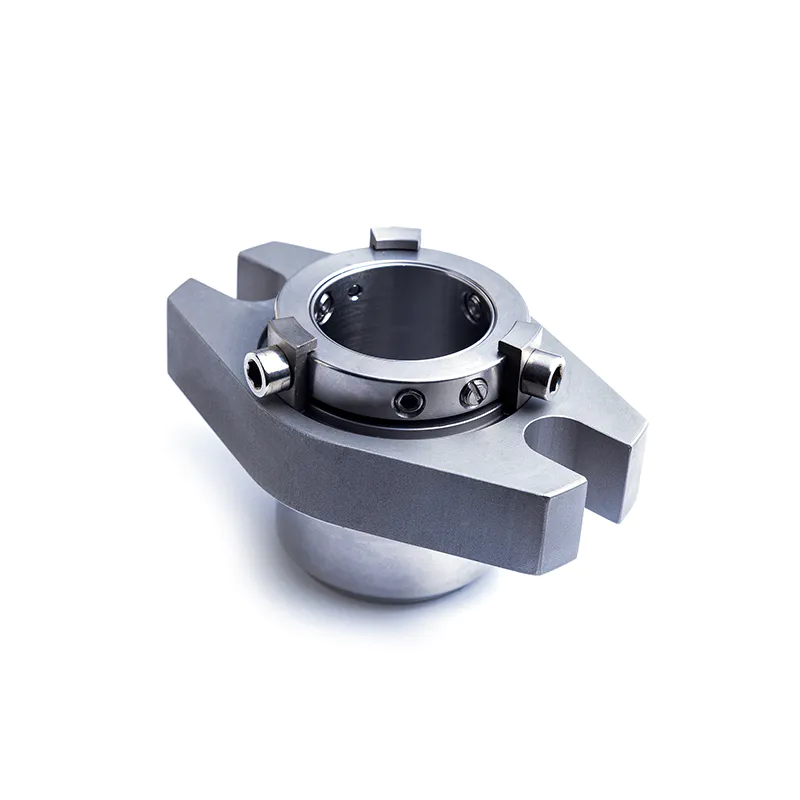

Heavy cross sections of the rotary elements resist excessive levels of corrosion. Utilizing a simple rugged open rotary unit design, aggressive, abrasive and viscous fluids can be sealed easier than with different ANSI seal varieties that incorporate shrouded spring rotaries. The RO sequence is on the market off the shelf in standard configurations for the entire popular chemical pumps provided at present. The floating throttle bushing has very close clearance over the seal sleeve and provides security when sealing oil, oil distillates, light hydrocarbons or hazardous fluids.

We design and build particular AST 80 seals for progressive cavity pumps and different systems that require greater than a regular seal. Seal face materials have all the time been challenged to supply dependable operation in low lubricity fluids. In the past, this problem was addressed by lubricating seal faces with a cool, clean exterior fluid. Although efficient, this solution adds working value throughout the life of the seal. Alternatively, twin seals operating on clean barrier fluid supply longevity with lower operating value, however higher initial cost for the required assist system.

If a pump is to be operated at low pressures, an unbalanced mechanical seal might be appropriate. However, in situations the place larger pressures are anticipated, balanced seals will show a more dependable resolution. Balanced mechanical seals are notably suited to higher operating pressures, sometimes above 200 PSIG. They are additionally a good choice when handling liquids with low lubricity and better volatility.