An Introduction To The Five Key Features Of

Dual systems have barrier fluids; the auxiliary seal pot must be in the best location, with the proper instrumentation and piping. You must take the Length of Straight Pipe at Suction under consideration—some older pump methods that always got here as a packaged skid embody a ninetyº elbow at suction proper earlier than the move enters the impeller eye.

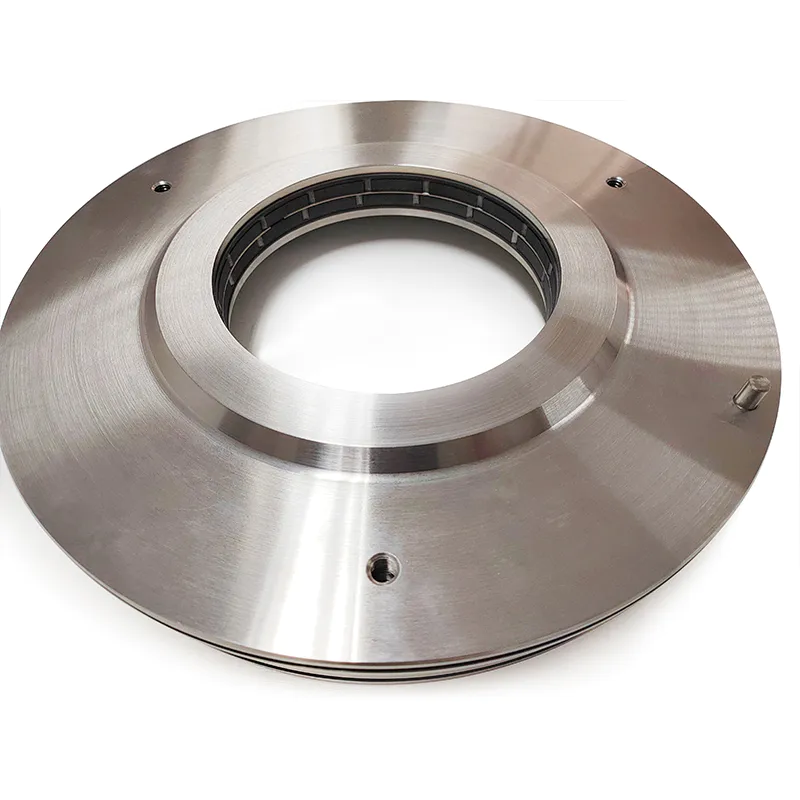

The mating ring can contain the seal face diameters, although this is not a requirement of the mating ring. To decrease main ring motion, the mating ring have to be mounted solidly and will type a perpendicular aircraft for the primary ring to run towards. Like seal rings, mating rings are available in many alternative shapes.

By definition, the mating ring is the non-versatile member of the mechanical seal. The design of the mating ring should enable for minimizing distortion and maximizing warmth transfer whereas considering ease of meeting and the static secondary sealing element.

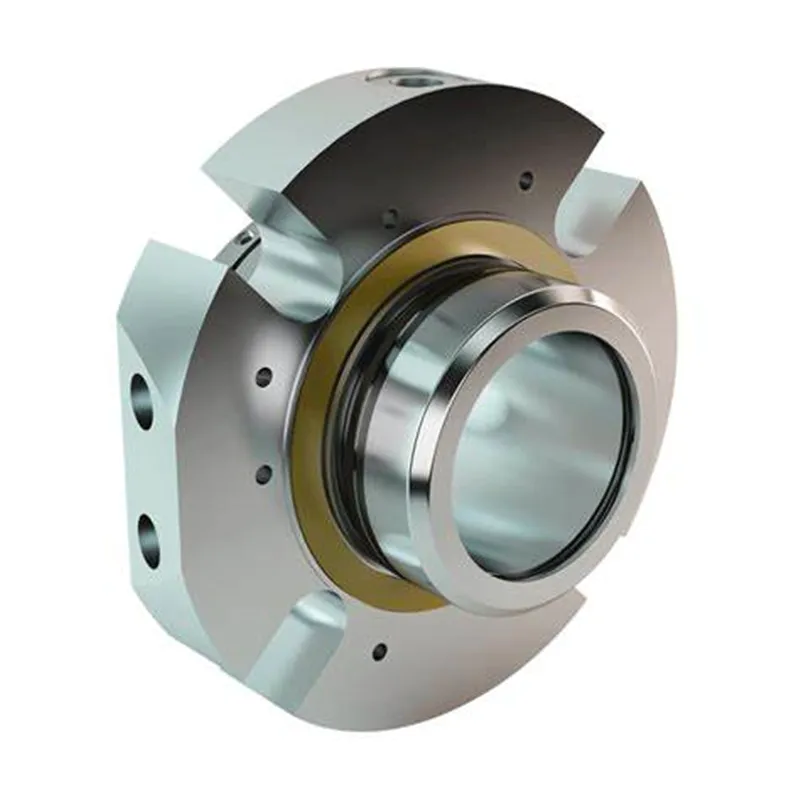

By definition, the seal ring is the axially versatile member of the tip-face mechanical seal. The design of the seal ring must enable for minimizing distortion and maximizing heat switch while considering the secondary sealing component, drive mechanism, spring and ease of meeting. Many seal rings contain the seal face diameters, although this isn't a requirement of the primary ring. The shape of the seal ring might range significantly in accordance with the incorporation of varied design features. In reality, the form of the seal ring is often probably the most distinct figuring out characteristic of a seal.

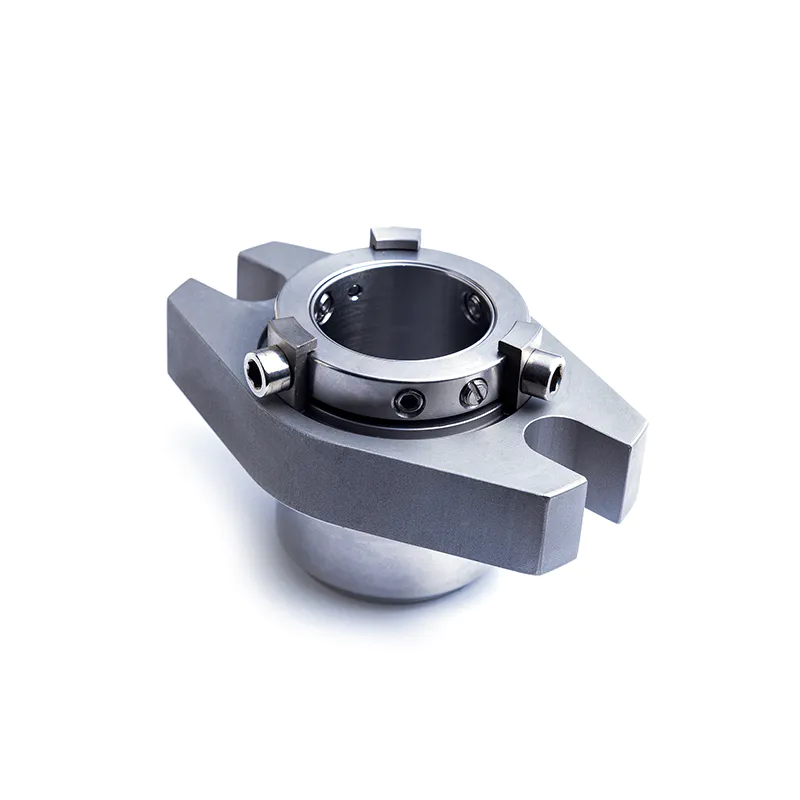

The amount of power required to drive a mechanical seal could be very less examine the pump having gland packing. You want a correct seal flush association, together with adequate cooling.

In common, face remedies present a way of modifying the strain distribution between the seal faces by way of hydrostatic or hydrodynamic topography. Seal face topography refers back to the three dimensional elements of the seal face surface. There are a variety of other ways in which “seals” may be categorized. Sometimes a reference to a “seal” may be to a sealing system whereas other times the reference is to a tool such as a gasket, an O-ring, compression packing, etc. In this article, the reference is to an finish-face mechanical seal.

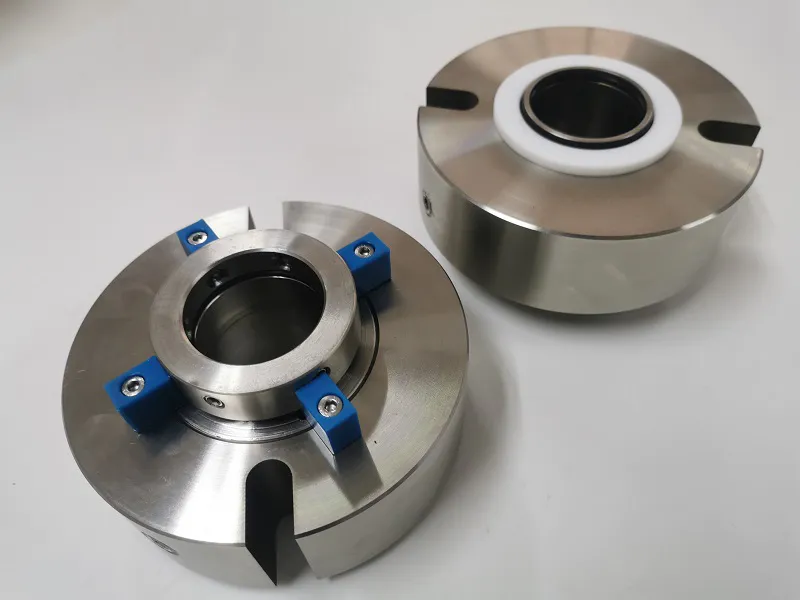

Secondary sealing elements for the seal ring are described as being either pusher or non-pusher in the axial direction. The term pusher is utilized to secondary seals that should be pushed backwards and forwards by the movement of the shaft or major ring whereas non-pusher secondary seals are static and related to bellows seal rings.

Secondary sealing components are gaskets which offer sealing between the seal ring and shaft and the mating ring and shaft . Typical secondary sealing elements include O-rings, wedges or rubber diaphragms. The secondary sealing parts aren't rotating relative to at least one another. The secondary sealing component for the mating ring is at all times static axially .

Bellows seals employ a static secondary seal (similar to an O-ring, excessive temperature graphite packing, or elastomeric bellows and axial movement is accommodated by contraction or growth of the bellows. The most typical seal face design is a plain, flat, clean floor but there are many special treatments meant for specific applications. The most typical objective for the face therapy is to scale back the magnitude of mechanical contact.

Guangzhou Lepu Machinery CO., LTD is one of the most-trusted manufacturing suppliers to the domestic markets.

go to Lepu Mechanical Seal to get an amazing offer at favorbale price. the Mechanical Seal China Cartridge Type Mechanical Seal actually works and is worth a try.

This is especially true when Guangzhou Lepu Machinery CO., LTD have got a global business that's building bridges between manufacturers and customers across the globe.