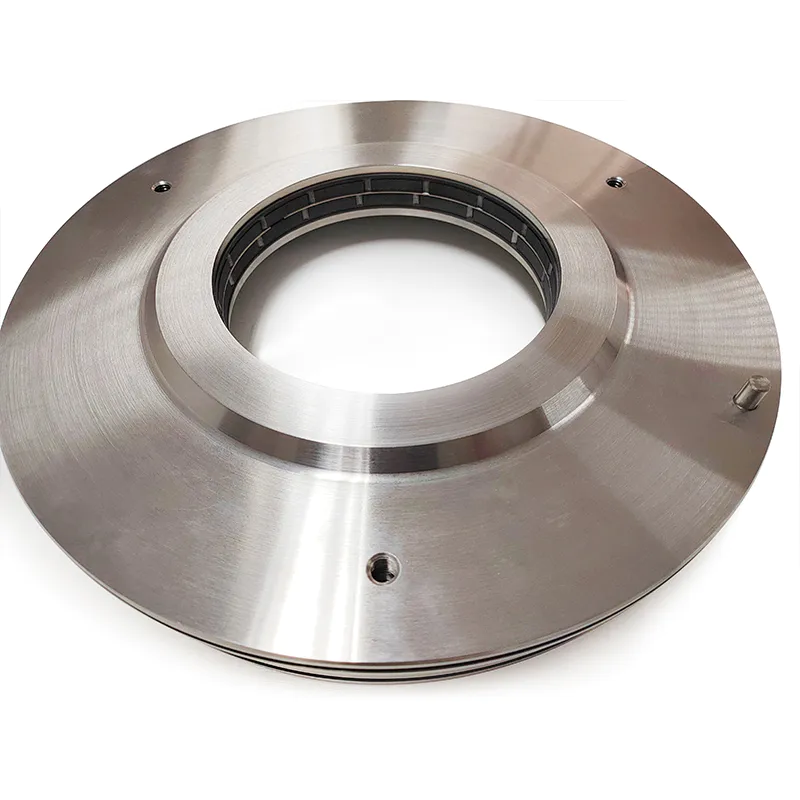

Dry Gas Seal

Friction characteristics of mechanical seals-

by:Lepu Seal

2021-04-12

Friction characteristics of mechanical seals

2017-07-25

Friction characteristics of mechanical seals:

The friction characteristics of mechanical seals include friction coefficient and working condition parameters, friction coefficient and medium pressure and peripheral speed.

Features

The friction coefficient is the ratio of the friction force F to the normal normal pressure W, and the working condition parameter G is the ratio of the fluid film viscous force to the fluid film carrying capacity W. The characteristic is dimensionless, reflecting the friction of the seal and the difficulty of forming the fluid film. It can not only be used to judge the friction state, but also can be used to determine the friction coefficient under different working conditions, and then determine the friction power consumption and temperature rise.

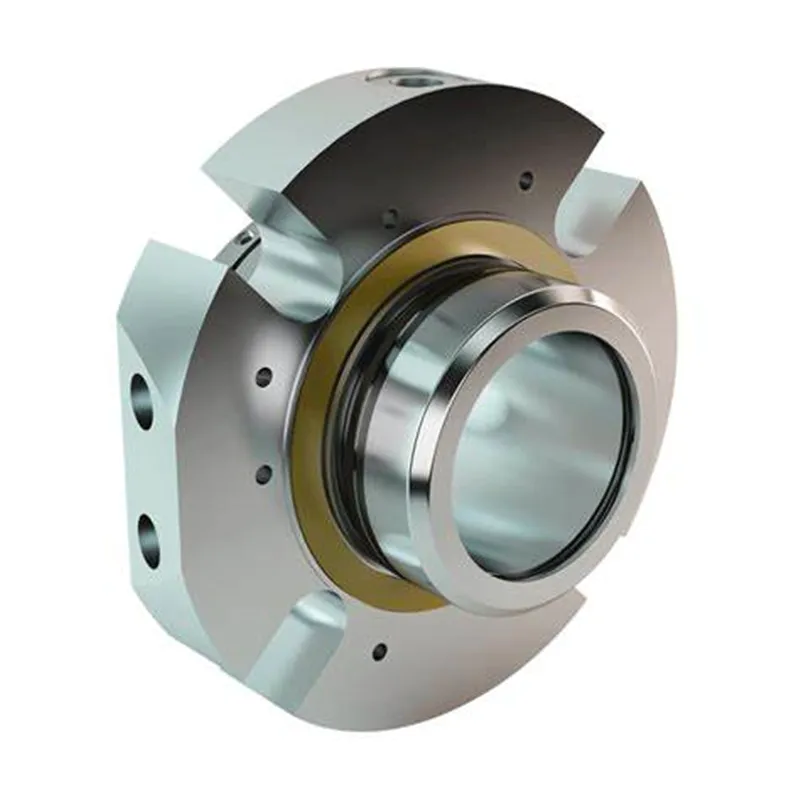

Figure 1-12 (a) shows the characteristics of the mechanical seal, which is obtained by testing several specimens with water, spindle oil and engine oil. The fluid lubrication area and the non-fluid lubrication area can be seen from the figure. Figure 1-12(b) shows the known characteristics of mechanical seals. The figure shows the relationship between the value of the leakage and the sealing limit and the relationship between the value and the waviness 6***** value. As the value of h increases, the value decreases. Figure 1-12(c) shows the characteristics of different film thicknesses, from which you can understand the film thickness under different and G.

Figure 1-12 Characteristics of mechanical seal

and features

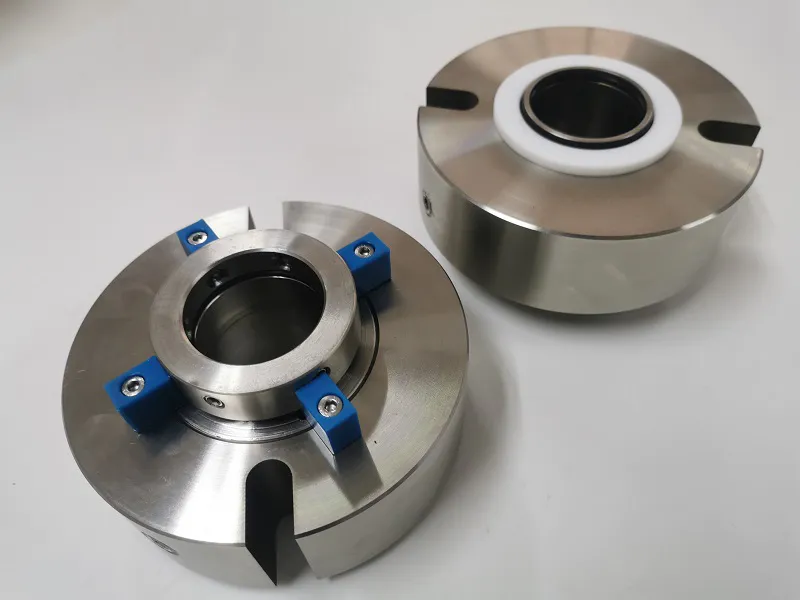

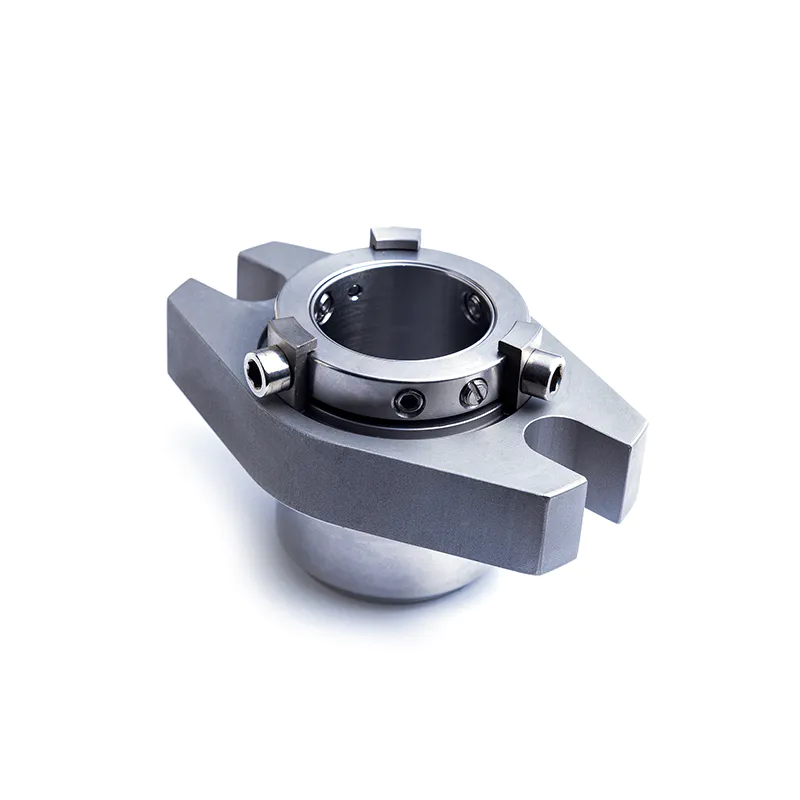

Figure 1-13 (a), (b) and the characteristics of different materials are listed. Among them, (a) and (b) belong to mixed friction and boundary friction, and (c) and (d) belong to dry friction. (c) is a pair of plastic and steel, (d) is a pair of carbon graphite and cast iron.

Figure 1-13(a) shows the mixed friction seal, which is similar to the fluid friction seal. As the contact pressure increases, the friction coefficient continues to decrease; as the peripheral speed increases, the friction coefficient may increase Or drop is related to the composition of fluid friction and the weight of the load.

Figure 1-13(b) shows the boundary friction seal. With the increase of pressure and peripheral velocity, the friction coefficient begins to decrease, and after reaching a certain value, the friction coefficient remains constant.

Figure 1-13 Sum characteristics under different working conditions and different materials

Figure 1-13 (c) and (d) are both dry friction seals. Plastics cannot be used in dry friction applications under high load. Because of its low thermal conductivity, it is not conducive to discharging frictional heat, so the sealing surface The temperature at the location can easily exceed the limit use temperature of the sealing material. The coefficient of friction increases with the increase in load and peripheral speed. Carbon graphite and cast iron are self-lubricating, and their laws are different from plastics.

261 mechanical seal

543.html,

The temperature rise of the sealing end surface of the mechanical seal The sealing characteristics of the mechanical seal

2017-07-25

Friction characteristics of mechanical seals:

The friction characteristics of mechanical seals include friction coefficient and working condition parameters, friction coefficient and medium pressure and peripheral speed.

Features

The friction coefficient is the ratio of the friction force F to the normal normal pressure W, and the working condition parameter G is the ratio of the fluid film viscous force to the fluid film carrying capacity W. The characteristic is dimensionless, reflecting the friction of the seal and the difficulty of forming the fluid film. It can not only be used to judge the friction state, but also can be used to determine the friction coefficient under different working conditions, and then determine the friction power consumption and temperature rise.

Figure 1-12 (a) shows the characteristics of the mechanical seal, which is obtained by testing several specimens with water, spindle oil and engine oil. The fluid lubrication area and the non-fluid lubrication area can be seen from the figure. Figure 1-12(b) shows the known characteristics of mechanical seals. The figure shows the relationship between the value of the leakage and the sealing limit and the relationship between the value and the waviness 6***** value. As the value of h increases, the value decreases. Figure 1-12(c) shows the characteristics of different film thicknesses, from which you can understand the film thickness under different and G.

Figure 1-12 Characteristics of mechanical seal

and features

Figure 1-13 (a), (b) and the characteristics of different materials are listed. Among them, (a) and (b) belong to mixed friction and boundary friction, and (c) and (d) belong to dry friction. (c) is a pair of plastic and steel, (d) is a pair of carbon graphite and cast iron.

Figure 1-13(a) shows the mixed friction seal, which is similar to the fluid friction seal. As the contact pressure increases, the friction coefficient continues to decrease; as the peripheral speed increases, the friction coefficient may increase Or drop is related to the composition of fluid friction and the weight of the load.

Figure 1-13(b) shows the boundary friction seal. With the increase of pressure and peripheral velocity, the friction coefficient begins to decrease, and after reaching a certain value, the friction coefficient remains constant.

Figure 1-13 Sum characteristics under different working conditions and different materials

Figure 1-13 (c) and (d) are both dry friction seals. Plastics cannot be used in dry friction applications under high load. Because of its low thermal conductivity, it is not conducive to discharging frictional heat, so the sealing surface The temperature at the location can easily exceed the limit use temperature of the sealing material. The coefficient of friction increases with the increase in load and peripheral speed. Carbon graphite and cast iron are self-lubricating, and their laws are different from plastics.

261 mechanical seal

543.html,

The temperature rise of the sealing end surface of the mechanical seal The sealing characteristics of the mechanical seal

Custom message