Tungsten Carbide Seals in Aerospace: Ensuring Safety and Reliability

Tungsten Carbide Seals in Aerospace: Ensuring Safety and Reliability

Introduction:

In the fast-paced world of aerospace engineering, safety and reliability are of utmost importance. With technological advancements constantly pushing the boundaries of what is possible, the need for robust and durable components is crucial. Tungsten carbide seals have emerged as an essential element in aerospace applications, offering unparalleled strength and performance. This article delves into the various aspects of tungsten carbide seals and their vital role in ensuring safety and reliability in the aerospace industry.

The Science behind Tungsten Carbide Seals:

1. Unveiling the Composition:

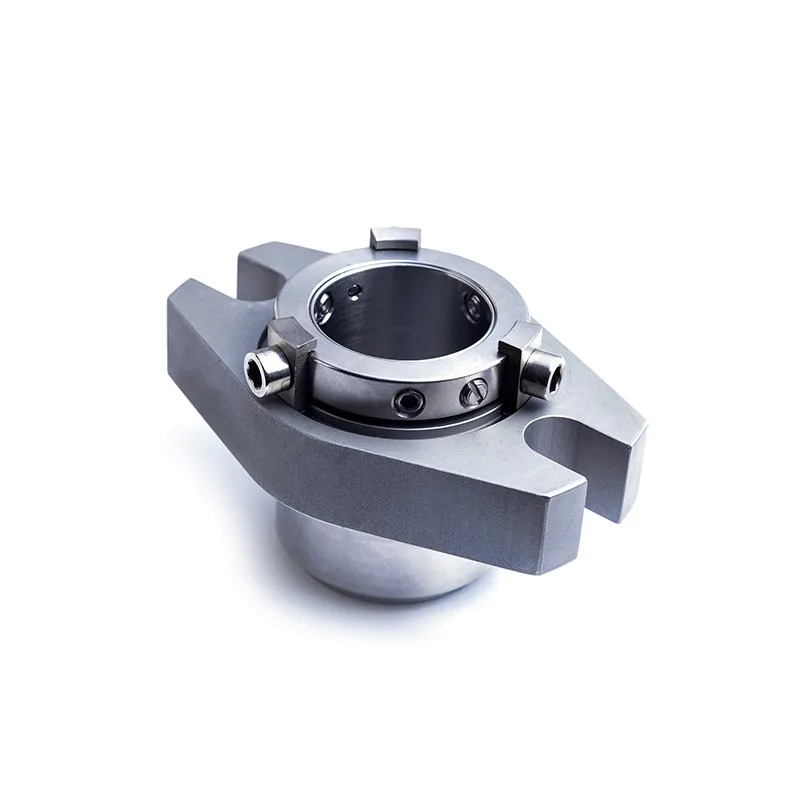

Tungsten carbide, known for its remarkable hardness, is composed of equal parts tungsten and carbon atoms. This unique combination results in a material that exhibits exceptional resistance to wear, corrosion, and high temperatures. The strength of tungsten carbide seals lies in their ability to withstand extreme conditions encountered in aerospace environments.

2. Understanding the Manufacturing Process:

The production of tungsten carbide seals begins by thoroughly blending tungsten powder and carbon black. This mixture is then compacted under high pressure and sintered at temperatures exceeding 2,700 degrees Celsius. The resulting hard and rigid structure lends the seals their characteristic toughness, making them ideal for aerospace applications.

Applications of Tungsten Carbide Seals in Aerospace:

1. Fuel Systems:

Fuel systems in aircraft demand absolute reliability to avoid catastrophic events. Tungsten carbide seals are employed in fuel pump shafts, ensuring leak-proof connections and preventing fuel contamination. The high resistance to corrosion and abrasion exhibited by tungsten carbide allows for extended service life without compromising safety.

2. Hydraulic Systems:

Hydraulic systems play a vital role in the operation of aircraft, controlling the movement of flaps, landing gear, and various other crucial components. Tungsten carbide seals find widespread use in hydraulic piston pumps and valves, providing excellent sealing capabilities under high pressure and temperature conditions. Their durability ensures the smooth functioning of hydraulic systems, minimizing the risk of failures.

3. Engine Components:

Aircraft engines operate under extreme conditions, enduring high temperatures, vibrations, and corrosive substances. Tungsten carbide seals are employed in critical engine components such as bearing systems, shafts, and turbine blades. These seals ensure effective lubrication, reduce friction, and prevent leakage, contributing to enhanced engine performance and safety.

4. Environmental Control Systems:

Maintaining a controlled environment within an aircraft is paramount for passenger comfort and safety. The Environmental Control System (ECS) facilitates air conditioning, heating, and ventilation. Tungsten carbide seals are utilized in ECS valves, actuators, and connectors, providing an airtight seal that prevents leakage and enables accurate control of temperature and pressure.

5. Landing Gear:

Landing gear is subjected to immense stress during takeoff and landing, necessitating robust and flawlessly functioning components. Tungsten carbide seals are employed in landing gear struts, ensuring smooth operations and preventing hydraulic fluid leaks. Their wear resistance properties make them an ideal choice for this critical aerospace application.

The Importance of Reliability and Safety:

Reliability and safety are paramount in the aerospace industry. The consequences of component failure can be catastrophic, resulting in loss of life, property, and reputation. Tungsten carbide seals are an integral part of ensuring the reliability and safety of aerospace systems. With their ability to withstand extreme conditions and maintain long-term performance, these seals contribute significantly to overall system integrity.

Conclusion:

Tungsten carbide seals have become indispensable in the aerospace industry, offering unparalleled performance, reliability, and safety. Their ability to withstand extreme conditions, resistance to wear and corrosion, and unmatched durability make them an ideal choice for critical aerospace applications. As technology continues to push the boundaries of aerospace engineering, the importance of robust components like tungsten carbide seals cannot be overstated. With ongoing advancements in material science, these seals will continue to play a pivotal role in ensuring the safety and reliability of aerospace systems for years to come.