Single Spring Mechanical Seals: Simplicity Meets Performance in Sealing

Single Spring Mechanical Seals:

Simplicity Meets Performance in Sealing

Introduction

Mechanical seals are vital components in various industries, providing a reliable and efficient solution for preventing leakage in rotating equipment. Among the different types of mechanical seals, single spring mechanical seals have gained immense popularity due to their simplicity and exceptional sealing performance. In this article, we will delve into the world of single spring mechanical seals, exploring their design, functionality, advantages, and applications.

Understanding Single Spring Mechanical Seals

1. What are single spring mechanical seals?

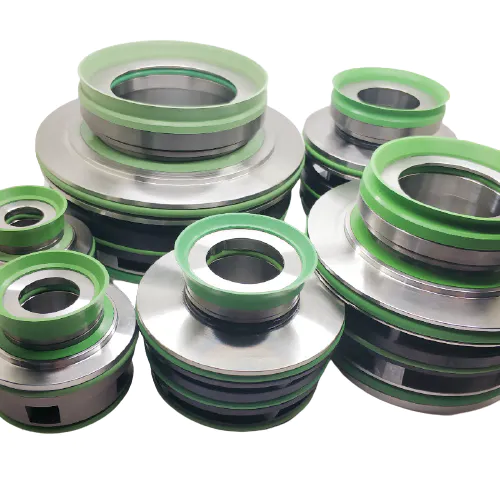

Single spring mechanical seals are compact devices that consist of a single coiled spring, often made of stainless steel, housed within a stationary and a rotating face. These seals are designed to create a dynamic seal between the shaft and pump housing, ensuring the prevention of leakage and safeguarding against the entry of contaminants.

2. How do single spring mechanical seals work?

The functionality of single spring mechanical seals is centered around the concept of generating radial force. When the rotating and stationary faces are brought into contact, the spring becomes compressed, generating a radial force that pushes the faces together, sealing the gap and preventing leakage. This mechanical force ensures a reliable and efficient seal, even in demanding operating conditions.

Advantages of Single Spring Mechanical Seals

1. Simplicity in design and installation

One of the key advantages of single spring mechanical seals is their simplicity in design and installation. With only one coiled spring involved, these seals are easier to handle and install compared to more complex seal designs. Their straightforward design ensures simplicity in maintenance and reduces the potential for human error during installation.

2. Enhanced sealing performance

Despite their simple design, single spring mechanical seals excel in terms of sealing performance. The radial force generated by the compressed spring ensures a tight and reliable seal, even in high-pressure environments. This feature allows single spring mechanical seals to effectively prevent leakage and maintain the integrity of the system.

3. Cost-effective solution

Another significant advantage of single spring mechanical seals is their cost-effectiveness. With a simplified design and fewer components, these seals are often more affordable than their multi-spring counterparts. Additionally, their ease of installation and maintenance minimizes downtime, resulting in cost savings for industries relying on efficient equipment operation.

Applications of Single Spring Mechanical Seals

1. Pump systems

Single spring mechanical seals find wide usage in pump systems across various industries. From water treatment plants to petrochemical refineries, these seals provide a robust sealing solution that ensures fluid containment and prevents contamination. Their ability to withstand high pressures and temperatures make them ideal for demanding pumping applications.

2. Food and beverage industry

In the food and beverage industry, maintaining hygiene and preventing contamination are critical. Single spring mechanical seals offer an excellent choice for sealing rotating equipment, such as mixers, blenders, and agitators. Their straightforward design facilitates easy cleaning and sterilization, meeting the stringent requirements of the industry.

3. HVAC systems

Heating, ventilation, and air conditioning (HVAC) systems heavily rely on efficient sealing to ensure optimal performance. Single spring mechanical seals provide a reliable sealing solution for HVAC pumps and motors, preventing any leakage or loss of refrigerants. Their ability to withstand varying operating conditions and pressures makes them an ideal choice in HVAC applications.

4. Oil and gas industry

The oil and gas industry operates in challenging environments where leakage prevention is crucial. Single spring mechanical seals excel in this industry, with their ability to handle high pressures and aggressive media. Whether in pumps, compressors, or turbines, these seals ensure the integrity of the equipment and prevent any potential environmental hazards.

5. Pharmaceutical and chemical industry

In the pharmaceutical and chemical industry, maintaining a sterile and controlled environment is vital. Single spring mechanical seals offer effective sealing solutions for tanks, reactors, and mixing equipment, preventing any contamination or escape of hazardous substances. Their reliable performance and ease of maintenance make them a preferred choice in these demanding industries.

Conclusion

Single spring mechanical seals combine simplicity with exceptional sealing performance, making them a popular choice across various industries. With their straightforward design, ease of installation, and cost-effectiveness, these seals provide reliable solutions for preventing leakage and ensuring equipment integrity. Their applications range from pump systems to food and beverage, HVAC, oil and gas, as well as the pharmaceutical and chemical industries. By incorporating single spring mechanical seals into their rotating equipment, industries can enhance operational efficiency while maintaining stringent safety standards.