O-Ring Mechanical Seals for Pharmaceutical Tablet Presses: Contamination Prevention and Product Quality

Importance of Contamination Prevention in Pharmaceutical Tablet Presses

Contamination prevention in pharmaceutical tablet presses is crucial for ensuring product quality and patient safety. O-Ring Mechanical Seals play a significant role in minimizing contamination risks and maintaining the desired level of product quality. In this article, we will explore the importance of contamination prevention and how O-Ring Mechanical Seals contribute to achieving it in pharmaceutical tablet presses.

Pharmaceutical tablet manufacturing requires a sterile environment to prevent any contamination that could compromise the quality and efficacy of the products. Even a small degree of contamination can lead to significant health risks and financial losses for pharmaceutical companies. Therefore, implementing effective contamination prevention measures is of utmost importance.

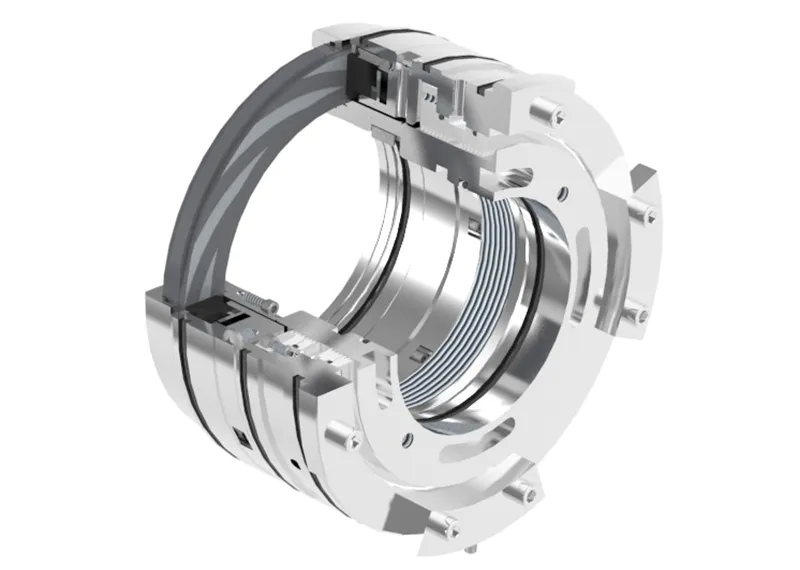

Understanding O-Ring Mechanical Seals

O-Ring Mechanical Seals are widely used in pharmaceutical tablet presses due to their ability to effectively seal off any potential points of contamination. These seals are made of high-quality elastomers, such as silicone or Viton, which are resistant to chemical and biological agents commonly used in pharmaceutical manufacturing processes. The O-Ring design allows for a reliable seal between various machine components, preventing any leakage or intrusion of contaminants.

Types of Contaminants in Pharmaceutical Tablet Presses

Pharmaceutical tablet presses are exposed to various types of contaminants, including airborne particles, microbial contamination, lubricating oils, and product cross-contamination. Each of these contaminants poses a unique threat to the final product's quality and can compromise patient safety if not controlled effectively. O-Ring Mechanical Seals play a pivotal role in preventing contamination from all these potential sources.

Sealing Technology for Contamination Prevention

O-Ring Mechanical Seals employ advanced sealing technology to create airtight and watertight seals, effectively shielding the tablet press from external contaminants. The precise design and material composition of these seals ensure they can withstand the harsh operating conditions, frequent cleaning, and sterilization procedures commonly employed in pharmaceutical manufacturing.

Moreover, O-Ring Mechanical Seals are designed to handle high pressures and temperature fluctuations without compromising their sealing capabilities. This robustness ensures the seals can maintain their effectiveness throughout the entire production process, preventing contaminants from entering critical areas such as tablet molds and compression zones.

Benefits of O-Ring Mechanical Seals for Pharmaceutical Tablet Presses

The utilization of O-Ring Mechanical Seals in pharmaceutical tablet presses brings numerous benefits to manufacturers, including:

1. Enhanced Product Quality: O-Ring Mechanical Seals create a reliable barrier against contamination, ensuring that the final product meets the highest quality standards. By preventing any entry of contaminants, manufacturers can minimize the risk of product recalls and ensure regulatory compliance.

2. Reduced Production Downtime: The robust nature of O-Ring Mechanical Seals allows for prolonged equipment uptime and reduced downtime. With fewer seal-related issues, tablet presses can operate smoothly, contributing to increased production output and efficiency.

3. Enhanced Equipment Lifespan: O-Ring Mechanical Seals contribute to the longevity of tablet presses by minimizing the wear and tear caused by contaminants. With a reduced risk of contamination-related damages, pharmaceutical companies can prolong the lifespan of their equipment and avoid costly replacements or repairs.

4. Improved Safety for Operators: O-Ring Mechanical Seals contribute to a safer work environment for operators by preventing exposure to hazardous chemicals and microorganisms. This, in turn, promotes occupational health and safety, fostering a more productive and responsible work culture.

In conclusion, the utilization of O-Ring Mechanical Seals in pharmaceutical tablet presses plays a crucial role in contamination prevention and maintaining product quality. These seals create a reliable barrier against various contaminants and contribute to the overall efficiency and reliability of tablet press machines. By investing in high-quality sealing technology, pharmaceutical companies can ensure patient safety, regulatory compliance, and long-term business success.