Lepu Seal - A Professional China Mechanical Seal Manufacturer providing Cartridge Seal, Grundfos Mechanical Seal And We offer free sample!

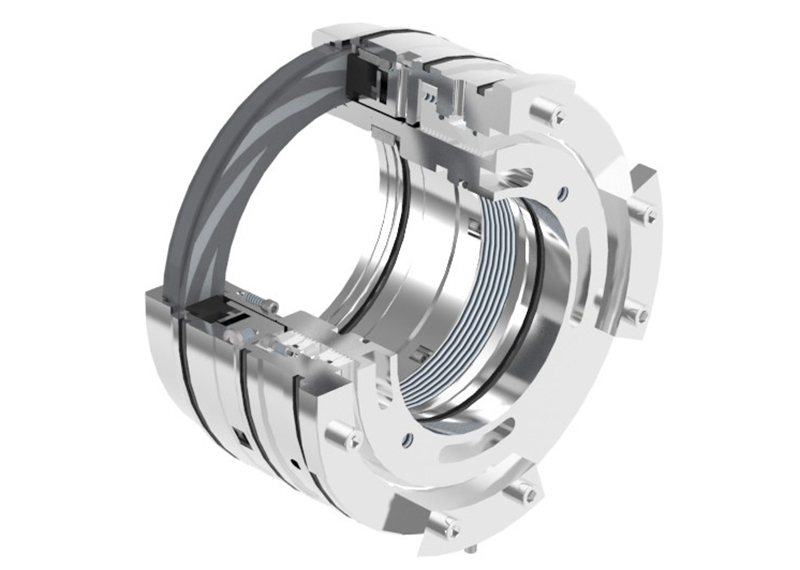

Replacement Dry Gas Seal LPDGS 801 For Centrifugal Compressors

The LPDGS-801 Dry Gas Seal is a non-contact mechanical seal that utilizes a thin layer of gas (typically nitrogen or process gas) as a lubricant between two end faces. This prevents process gas from leaking from the compressor to the atmosphere. Unlike traditional oil seals, dry gas seals offer low friction, high-speed operation, and minimal wear.

Working parameters:

Maximum Temperature: 250°F (121°C)

Typical Operating Pressure: 0–15 psi (0–1 bar)

Maximum Containment Pressure: 1,500 psi (103 bar)

Maximum Speed: 6,000 ft/min (30.5 m/s)

LPDGS-801, A compressor process seals which is designed to seal the rotating assembly in the stationary compressor case to prevent the process gas in the compressor from getting to the atmosphere and to prevent the atmosphere from getting into the process gas.

Centrifugal compressors have seals on the rotating shafts that prevent the high-pressure natural gas from escaping the compressor casing. These seals can be high-pressure oil ("wet”) seals or mechanical gas (“dry”) seals, which act as barriers against escaping gas.

LPDGS-801 dry gas mechanical seal is a special design for centrifugal comrepssors, under normal circumstances, the primary seal bears the full pressure of the medium, and the secondary seal runs under low pressure or normal pressure. When the primary seal fails completely, the secondary seal functions as the main seal, and it can run safely for at least 8 hours.

The secondary seal is injected with buffer gas under pressure, and is isolated by comb seals to prevent the primary leaking medium from contaminating the secondary dry gas seal. The process medium leaked from the primary seal is taken to the torch combustion / collection tank for centralized discharge, safe and environmentally friendly ; The buffer gas under pressure can reduce the vaporization of the medium on the primary seal face, improve the lubrication effect of the mechanical seal, and extend the seal service life.

LPDGS-801 is a special design for centrifugal compressors, in the past years, this dry gas seal running with excellent record, and widely use for toxic and hazardous, flammable and explosive dangerous fluid media. Such as ethylene, propylene, liquefied gas, ammonia, MTBE, butadiene, aromatics, benzene media

PRODUCT TECHNICAL SPECIFICATION

Sealing Face: Carbon, SIC,

Pressure: 0 ~ 10MPa

Temperature: -104 ~ 260 ℃

Speed: ≤3600r / min

Advantages Of Dry Gas seals

● Improved reliability: Dry gas seals have fewer parts than traditional seals, reducing the potential for failure. They also eliminate the risk of seal leakage, which can cause damage to the environment, equipment, and personnel.

● Reduced maintenance costs: Dry gas seals require less maintenance than liquid lubricated seals because they do not require a liquid supply, filtration, or cooling system. This results in lower operating costs and increased efficiency.

● Increased safety: The elimination of the liquid lubricant reduces the risk of fires and explosions. Additionally, dry gas seals are typically designed to detect leaks and prevent catastrophic failures.

● Better performance: Dry gas seals are capable of operating at higher speeds and pressures than traditional seals, resulting in improved equipment performance and increased efficiency.

● Environmentally friendly: Dry gas seals eliminate the need for a liquid lubricant, reducing the potential for environmental contamination. They are also more energy-efficient than traditional seals, reducing greenhouse gas emissions and contributing to a more sustainable future.

PRODUCT ADVANTAGE

- Leak-proof – Provides high seal integrity

- Low maintenance – Reduces wear

- Environmentally friendly – No oil leaks or contamination

- High efficiency – Reduces energy loss and improves performance

- Longer service life – Due to contactless operation

Common signs that dry gas needs to be replaced:

- Abnormal compressor vibration

- Gas leaks or sudden pressure drops

- Excessive heat

- Increased power consumption

Prompt maintenance and monitoring are essential to maximize seal performance and service life.

PRODUCT APPLICATION

aIndustries Relying on Dry Gas Mechanical Seals

Dry gas mechanical seals are critical components across numerous industries. They are particularly crucial in applications where preventing gas contamination or leakage is crucial. These industries include oil and gas production, refining, petrochemicals, aerospace, and more. Dry gas mechanical seals help maintain process integrity and protect equipment in harsh, high-risk environments.

- Natural Gas Compressors

- Petrochemical Plants

- Oil Refineries

- Hydrogen Compression

- Turbomachinery in Power Plants

Role in High-Pressure Applications

Dry gas mechanical seals are widely used in high-pressure applications, such as compressors in the oil and gas industry. The ability to establish and maintain a hermetic seal under harsh conditions is crucial to preventing operational failures and protecting machinery and the environment, highlighting their importance within the dry gas mechanical seal industry.

Lepu Seal provides reliable and cost-effective dry gas sealing solutions for centrifugal compressors

Our innovative sealing solution eliminates the need for seal gas boosters, protects dry gas seals from contamination, and reduces maintenance and downtime costs.

The seal protector, located between the dry gas seal and the process-side seal, remains open during operation to prevent contamination. During static or low-speed conditions, it ensures that only clean, dry process gas reaches the dry gas seal.

Benefits of the Lepu Dry Gas Seals solution include:

● Improved reliability: Our simplified design reduces the risk of component failure.

● Reduced costs: Operating and maintenance costs are reduced.

● Minimized footprint: Our system can replace seal gas boosters, saving space.

● Lower emissions: Seal Protect uses less electricity, resulting in lower emissions.

● Seal Protect is compatible with most new compressor trains and can be retrofitted into existing installations to improve reliability.

Why choose Lepu Seal dry gas seals?

Lepu Seal specializes in providing high-quality dry gas seals that meet a wide range of industrial needs. Whether you need to upgrade your compressor system or replace worn seals, our products are trusted by a wide range of industries in India and abroad.

FAQ

1. What are dry gas seals used for?

Dry gas seals are used in high-speed rotating equipment, such as compressors, to prevent gas leakage without the use of liquid lubricants.

2. How do dry gas seals work?

They work by maintaining a thin film of gas between two sealing surfaces, preventing direct contact and sealing process gases under high pressure.

3. What types of dry gas seals are there?

Common types include single dry gas seals, tandem dry gas seals, and double dry gas seals, each offering varying degrees of sealing and safety.

4. Why are dry gas seals better than oil seals?

They offer lower maintenance costs, higher reliability, and eliminate the risk of oil contamination, resulting in greater efficiency and environmental friendliness.

5. When should dry gas seals be replaced?

Replace dry gas seals if you notice leaks, abnormal vibrations, increased power consumption, or overheating in your compressor system.

Guangzhou Lepu Machinery Co., Ltd.

Add:

No. 5, Yunkai Road, Huangpu District, Guangzhou, China

Tel:

+86-020-36158139

+86-020-36158280

E-mail:

mark@lepuseal.com

Fax: +86-020-36158281

Contact Person: Mr. Mark Ao

Whatapps: +86-18903009893

Sealing Face: Carbon, SIC,

Sealing Face: Carbon, SIC,