Lepu Seal - A Professional China Mechanical Seal Manufacturer providing Cartridge Seal, Grundfos Mechanical Seal And We offer free sample!

Flowserve Gaspac Dry Gas Seals

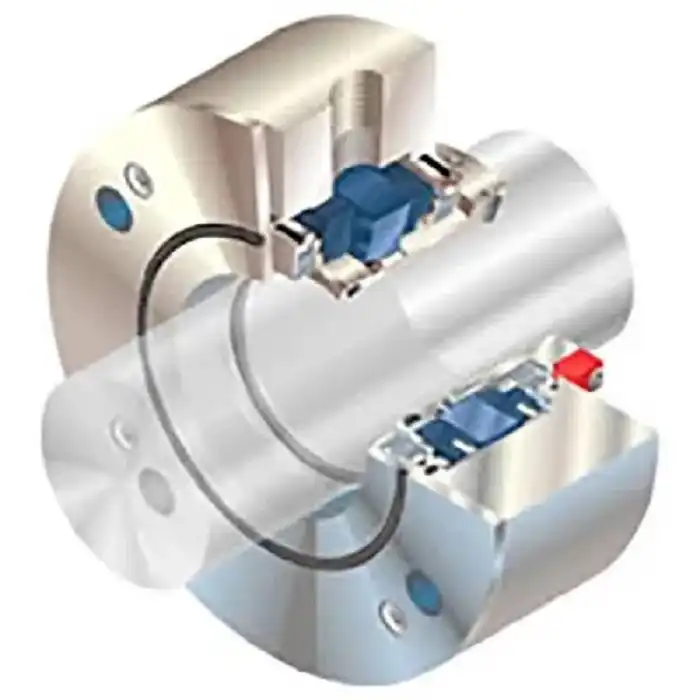

Gaspac Dry Gas Seals

The dry gas seal is an advanced sealing technology designed to prevent the escape of process gases in rotating equipment, particularly in centrifugal compressors and pumps. Unlike traditional mechanical seals that rely on a liquid or lubricating film, a dry gas seal operates by creating a thin barrier of high-pressure gas between the stationary and rotating components. Dry gas seals are non-contacting, dry-running mechanical face seals that consist of a mating (rotating) ring and a primary (stationary) ring.

Dry gas seals are mechanical seals but use other chemicals and functions so that they do not contaminate a process. These seals are typically used in a harsh working environment such as oil exploration, extraction and refining, petrochemical industries, gas transmission and chemical processing.

Flowserve gaspac is a typical dry gas seal, and is very popular in the world. because of the below advantages of dry gas seal:

⬤ Reduced operating costs

⬤ Increased reliability

⬤ Increased efficiency

⬤ Maintenance advantage

⬤ Improved safety

⬤ Environmental impact

Recommended Applications of Flowserve gaspac Dry Gas Seal

Conventional Steam

Combined Cycle

Concentrated Solar Power (CSP)

Biomass & MSW

Geothermal

Chemicals

Basic (Organic & Inorganic)

Specialty (Fine & Consumer)

Biofuels

Pharmaceutical

Petrochemicals

Oil & Gas

Upstream Exploration & Production

Midstream Transportation

Downstream Processing

What Is The Leakage Rate Of Dry Gas Seal?

The leakage rate of a dry gas seal is a critical parameter in the operational efficiency and environmental compliance of rotating equipment, particularly compressors and pumps. Dry gas seals operate by employing a thin film of gas to mitigate contact between sealing surfaces, which significantly minimizes wear and tear while providing superior sealing capabilities compared to traditional liquid seals. Typically, the leakage rates associated with high-quality dry gas seals can be as low as 1 to 10 standard cubic feet per minute (scfm), depending on factors such as pressure differentials, temperature variations, and specific application conditions. These advanced sealing solutions are designed not only for optimum performance but also for minimal emissions; therefore, understanding their leakage rates is essential for industries that prioritize safety and environmental stewardship. By maintaining effective control over these rates through rigorous engineering practices and regular maintenance schedules, operators can achieve both enhanced reliability of their machinery and reduced operational costs linked to lost product or gases escaping into the atmosphere.

SYSTEM DESCRIPTION FOR GAS SEAL

PRODUCT TECHNICAL SPECIFICATION

- high pressure applications up to 450 bar

- high speeds: slow-roll up to 240 m/s (800 ft/s) [ ~ 850 km/h (530 miles/hr) ]

- high temperatures: -135 C up to 230 C

- Big diameters up to 360 mm (e.g. for the LNG market)

Dry gas seal case we made before

Lepu Seal is One Of The Best Manufacturer of Gas Seal In China

Economic and environmental benefits of dry gas seals include:

- Gas Leak Rates. During normal operation, dry seals leak at a rate of 0.5 to 3 scfm across each seal, depending on the size of the seal and operating pressure. While this is equivalent to a wet seal’s leakage rate at the seal face, wet seals generate additional emissions during degassing of the circulating oil. Gas from the oil is usually vented to the atmosphere, bringing the total leakage rate for dual wet seals to between 40 and 200 scfm, depending on the size and pressure of the compressor.

- Mechanically Simpler. Dry seal systems do not require elaborate oil circulation components and treatment facilities.

- Reduced Power Consumption. Because dry seals have no accessory oil circulation pumps and systems, they avoid “parasitic” equipment power losses. Wet systems require 50 to 100 kW per hour, while dry seal systems need about 5 kW of power per hour.

- Improved Reliability. The highest percentage of downtime for a compressor using wet seals is due to seal system problems. Dry seals have fewer ancillary components, which translates into higher overall reliability and less compressor downtime.

- Lower Maintenance. Dry seal systems have lower maintenance costs than wet seals because they do not have moving parts associated with oil circulation (e.g., pumps, control valves, relief valves).

- Elimination of Oil Leakage from Wet Seals. Substituting dry seals for wet seals eliminates seal oil leakage into the pipeline, thus avoiding contamination of the gas and degradation of the pipeline.

Guangzhou Lepu Machinery Co., Ltd.

Add:

No. 5, Yunkai Road, Huangpu District, Guangzhou, China

Tel:

+86-020-36158139

+86-020-36158280

E-mail:

mark@lepuseal.com

Fax: +86-020-36158281

Contact Person: Mr. Mark Ao

Whatapps: +86-18903009893