Maximizing Durability: Materials and Design Features of Blackmer Pump Seals

The Importance of Pump Seals in Maximizing Durability

Pump seals play a crucial role in ensuring the efficient and reliable operation of industrial pumps. These seals are responsible for preventing leakage and maintaining the integrity of the pump system. When it comes to seal selection, durability is a key factor that cannot be overlooked. In this article, we will explore the various materials and design features of Blackmer pump seals that are specifically engineered to maximize durability and optimize performance.

The Role of Pump Seals

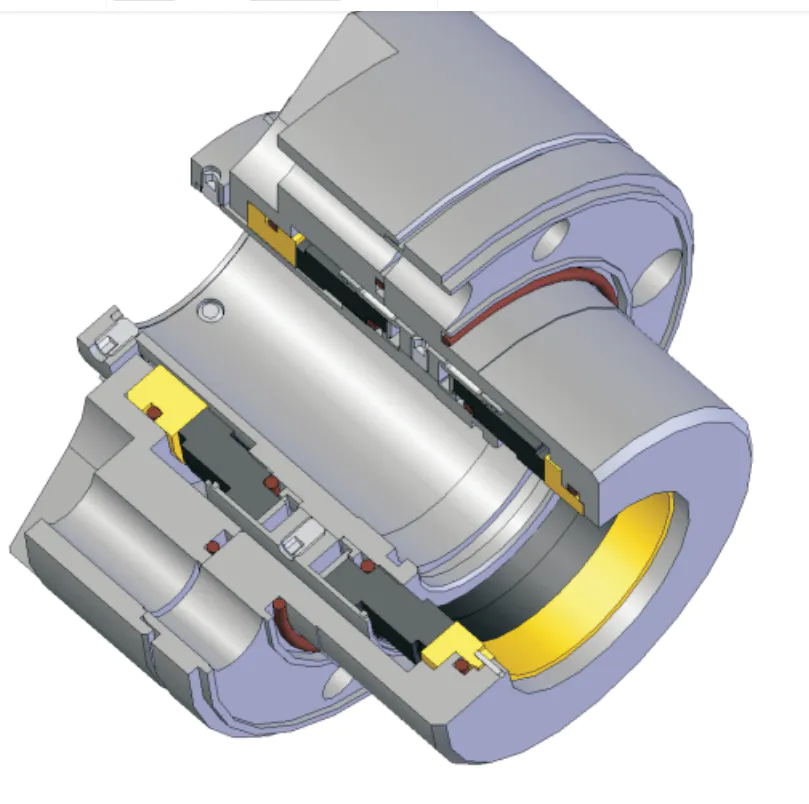

Before delving into the specific features of Blackmer pump seals, it is essential to understand the role they play in pump systems. Pump seals are essentially used to create a seal between the rotating shaft and stationary housing of the pump. Their primary function is to prevent leakage and maintain the pressure and flow rate within the pump.

Without an effective seal, there is a risk of fluid leakage, which can lead to significant operational issues such as reduced efficiency, increased downtime, and potential environmental hazards. Therefore, selecting the right seal that offers durability and reliability is critical for the smooth functioning of pump systems.

High-Quality Materials for Enhanced Durability

To maximize the durability of pump seals, the selection of high-quality materials is of utmost importance. Blackmer, a leading manufacturer in the industry, understands this need and incorporates premium materials into their seal designs.

1. Carbon: Carbon is one of the most commonly used materials in pump seals due to its excellent performance characteristics. It offers a combination of good chemical resistance, high wear resistance, and low friction properties. Carbon-based pump seals are ideal for applications involving abrasive fluids or high temperatures.

2. Ceramic: Ceramic seals are well-known for their extreme hardness and superior resistance to wear. They are typically used in applications where there is a need for high mechanical strength and resistance to corrosion. Ceramic-based seals excel in demanding environments that involve handling aggressive chemicals or abrasive substances.

3. Stainless Steel: Stainless steel is another popular material choice for pump seals, particularly in applications where corrosion resistance is a top priority. It is highly resistant to rust and can withstand harsh operating conditions. Stainless steel pump seals are widely used in industries such as chemical processing, food and beverages, and wastewater treatment.

Design Features for Enhanced Performance

In addition to the material selection, the design features of pump seals also contribute to their durability and overall performance. Blackmer incorporates several design elements that distinguish their pump seals from others on the market.

1. Multiple Spring Designs: Blackmer pump seals utilize various spring designs to ensure optimal performance in different operating conditions. These springs provide consistent pressure on the seal faces, maintaining contact and preventing leakage. The design also accommodates thermal expansion, ensuring a secure seal throughout the pump's temperature fluctuations.

2. Balanced Seal Arrangements: To counteract the effects of pressure on pump seals, Blackmer employs balanced seal arrangements. These arrangements apply opposing forces to balance the hydraulic pressure exerted on the seal faces, resulting in reduced wear and extended seal life. Balanced seal arrangements are particularly beneficial in applications where pumps operate at high pressures or handle viscous fluids.

3. Robust Seal Faces: Blackmer pump seals are designed with robust seal faces that are specifically engineered for enhanced durability. These seal faces are highly wear-resistant and can withstand the rigorous conditions of industrial pump operations. The use of durable seal faces minimizes the risk of premature failure, ensuring longer service life and increased uptime.

The Benefits of Choosing Blackmer Pump Seals

Investing in high-quality pump seals, such as those offered by Blackmer, can yield numerous benefits for industrial operations. Some of the advantages of choosing Blackmer pump seals include:

1. Reduced Downtime: With their exceptional durability and extended service life, Blackmer pump seals help minimize downtime due to seal failures. This translates to increased productivity and cost savings for businesses.

2. Enhanced Efficiency: The high-performance materials and design features used in Blackmer pump seals contribute to improved pump efficiency. By reducing leakage and maintaining optimal pressure levels, these seals help optimize the overall performance of the pump system.

3. Increased Safety: The reliable sealing provided by Blackmer pump seals reduces the risk of hazardous fluid leaks, thus enhancing safety in industrial environments. This is particularly crucial in applications involving toxic, flammable, or environmentally harmful substances.

4. Extended Maintenance Intervals: Blackmer pump seals' resistance to wear and degradation allows for longer maintenance intervals. This means less frequent seal replacements, resulting in reduced maintenance costs and downtime.

In conclusion, when it comes to maximizing durability in pump systems, the selection of high-quality materials and the incorporation of well-engineered design features are paramount. Blackmer pump seals excel in both these aspects, offering exceptional durability, reliability, and performance. By investing in Blackmer pump seals, industrial operators can significantly enhance the efficiency, safety, and productivity of their pump systems, leading to long-term cost savings and operational success.