Grundfos Pump Seals: A Comparative Analysis of Seal Performance in Various Operating Conditions

Grundfos Pump Seals: A Comparative Analysis of Seal Performance in Various Operating Conditions

Introduction

Grundfos pumps are renowned for their efficiency and reliability in a wide range of applications. One critical component that ensures the smooth operation of these pumps is the seal. In this article, we will conduct a comprehensive analysis of Grundfos pump seals and evaluate their performance in different operating conditions. We will explore the factors affecting seal performance, compare various seal types, and discuss their suitability for specific applications.

Seal Design Considerations

A well-designed pump seal is crucial for preventing leaks and maintaining the integrity of the pump system. When it comes to Grundfos pump seals, several design considerations influence their performance. These include the type of sealing mechanism, materials used, and the sealing arrangement. Let's delve into these factors in detail.

1. Sealing Mechanism:

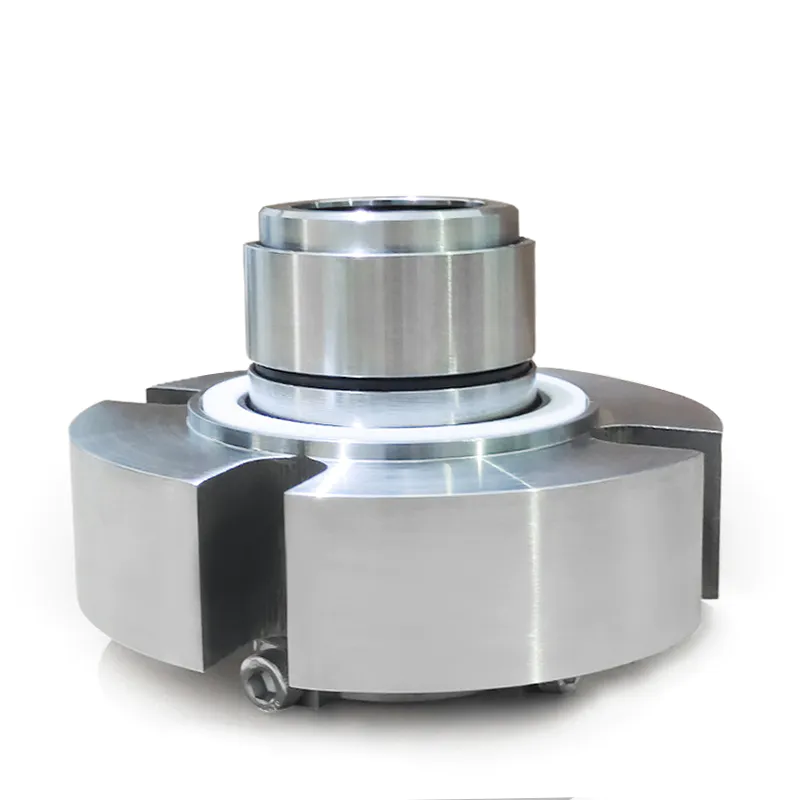

Grundfos pump seals typically employ either mechanical or labyrinth sealing mechanisms. Mechanical seals are composed of a rotating face against a stationary face, creating a seal that prevents fluid leakage. Labyrinth seals, on the other hand, use a series of chambers and channels to redirect any leaked fluid away from the system. Both mechanisms have their advantages and are suitable for different operating conditions.

2. Material Selection:

The choice of seal material significantly impacts its performance and longevity. Grundfos utilizes a variety of materials, including carbon, ceramic, tungsten carbide, and various elastomers. Carbon offers excellent chemical resistance and is ideal for handling fluids with low pH levels. Ceramic seals, known for their exceptional wear resistance, can withstand high pressures and temperatures. Tungsten carbide seals are preferred in abrasive applications, where reliability and durability are paramount.

3. Sealing Arrangement:

Grundfos pump seals are available in several arrangement configurations, such as single seal, double seal, and cartridge seal designs. Single seals are commonly used in applications with low risks of leakage. Double seals provide an additional layer of protection by incorporating a secondary seal as a backup. Cartridge seals, comprising multiple components preassembled in a self-contained unit, simplify installation and maintenance.

Comparative Performance Analysis

Now, let's compare the performance of different Grundfos pump seals in various operating conditions. Highlighted below are the key factors influencing seal performance:

1. Fluid Compatibility:

Different fluids have varying chemical compositions, temperatures, and pressures. Grundfos pump seals should be compatible with the specific fluid being pumped to ensure maximum seal integrity. For instance, elastomeric seals are well-suited for water-based fluids, while chemically resistant materials like PTFE excel with corrosive chemicals.

2. Temperature and Pressure:

Operating conditions involving high temperatures and pressures can pose challenges to seal performance. Grundfos offers seals capable of withstanding extreme environments, allowing them to maintain their sealing effectiveness even under demanding conditions.

3. Abrasive Environments:

In applications where the pumped fluid contains abrasive particles, the seal faces can wear prematurely. Grundfos pump seals with robust materials, such as tungsten carbide, provide exceptional resistance against abrasion, extending the seal's service life significantly.

4. Environmental Constraints:

Environmental factors, such as exposure to moisture, dust, or corrosive gases, can impact seal performance. Grundfos pump seals that incorporate appropriate sealing mechanisms, like labyrinth seals, minimize the effects of such external elements, ensuring optimal performance in challenging environments.

5. Operational Lifespan:

The operational lifespan of a seal depends on various factors, including the quality of materials, proper installation, and regular maintenance. Grundfos pump seals are designed to provide extended service intervals, reducing downtime and maintenance costs, resulting in enhanced overall pump efficiency.

Conclusion

Grundfos pump seals play a critical role in maintaining the integrity of pump systems in various operating conditions. By considering factors such as sealing mechanism, material selection, and sealing arrangement, Grundfos ensures their seals meet the requirements of different applications. Whether it's handling corrosive chemicals, abrasive fluids, or extreme temperatures and pressures, Grundfos pump seals offer reliable and efficient performance. By investing in high-quality seals and regularly monitoring their condition, pump operators can maximize the lifespan of their equipment and minimize potential risks.