Exploring New Frontiers: Emerging Applications of Blackmer Pump Seal Technology

In the ever-evolving world of industrial applications, the demand for reliable and efficient pumping solutions continues to grow. One technology that is reshaping the landscape is the innovative Blackmer pump seal technology. With its exceptional performance, durability, and versatility, this cutting-edge solution is revolutionizing various industries, allowing them to explore new frontiers. From chemical processing to oil and gas production, the applications of Blackmer pump seal technology are truly limitless.

The Evolution of Pump Seals: From Traditional to Cutting-Edge

Traditionally, mechanical seals have played a critical role in preventing leakage and ensuring efficient operation of pumps. However, these conventional seals often suffer from limitations, such as increased downtime, high maintenance costs, and compatibility issues with different fluids. In recent years, the emergence of Blackmer pump seal technology has transformed the landscape of seal solutions, offering superior performance and addressing the shortcomings of traditional seals.

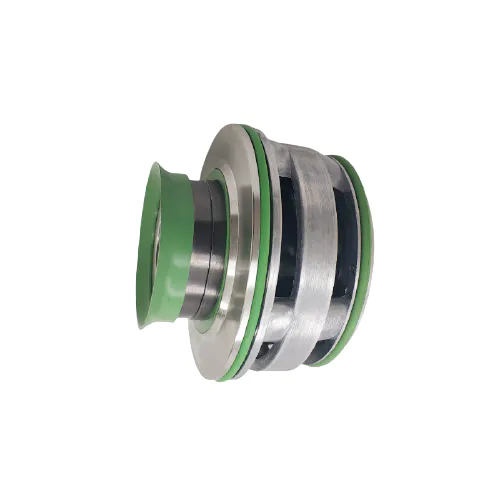

Blackmer pump seals feature innovative design elements, including advanced materials, unique seal face geometries, and state-of-the-art sealing mechanisms. These advancements have enabled these seals to achieve exceptional levels of reliability, durability, and efficiency. With enhanced wear resistance, reduced friction, and improved sealing capabilities, Blackmer pump seals are increasingly becoming the go-to choice for industries seeking optimal performance and long-term cost savings.

Enhancing Efficiency: Blackmer Pump Seals in Chemical Processing

Chemical processing is an industry where precision and reliability are paramount. Any leakage or operational disruptions can have disastrous consequences, leading to safety hazards, environmental pollution, and significant financial losses. This is where Blackmer pump seals shine, providing an unmatched level of performance.

Blackmer pump seals have been extensively utilized in various chemical processing applications, including the transfer of corrosive liquids, solvents, and volatile chemicals. The robust construction of these seals, combined with their ability to handle a wide range of fluids, makes them ideal for demanding chemical processes. Whether it's in pharmaceutical manufacturing, petrochemical refining, or agrochemical production, Blackmer pump seals continue to deliver reliability and efficiency, ensuring optimal performance and safety.

Additionally, Blackmer pump seals' unique sealing mechanisms effectively prevent the ingress of contaminants and eliminate the risk of process fluid leakage. This not only enhances the longevity of the seals but also eliminates the potential for cross-contamination, maintaining product integrity and purity. Furthermore, the reduced maintenance requirements of these seals significantly contribute to improving overall operational efficiency in chemical processing plants, reducing downtime, and minimizing associated costs.

Unleashing Potential: Blackmer Pump Seals in Oil and Gas Production

The oil and gas industry operates in harsh and demanding environments, characterized by high pressures, extreme temperatures, and corrosive fluids. In such conditions, ensuring reliable and efficient pumping is vital to the success of extraction, refining, and distribution processes. Blackmer pump seals are increasingly gaining popularity in this sector due to their exceptional ability to withstand these challenging conditions.

One key feature of Blackmer pump seals is their compatibility with a wide range of fluids, including crude oil, natural gas liquids, and various petroleum-based products. This versatility allows them to be effectively deployed in different applications throughout the oil and gas production cycle. Whether it's offshore drilling, wellhead compression, or refineries, Blackmer pump seals play a crucial role in maintaining operational efficiency and reducing downtime.

Moreover, Blackmer pump seals' cutting-edge materials and designs ensure exceptional performance even under extreme conditions. They exhibit high resistance to wear, erosion, and chemical attack, guaranteeing prolonged service life in the harshest environments. By minimizing leakage and maximizing efficiency, these seals contribute to optimized production processes, reduced maintenance costs, and enhanced safety in the oil and gas industry.

Revolutionizing Hygienic Applications: Blackmer Pump Seals in Food and Beverage Industries

In the food and beverage industries, maintaining stringent hygiene standards is of utmost importance. Contamination of products can lead to health risks, regulatory non-compliance, and reputational damage. Blackmer pump seals are at the forefront of ensuring hygienic operations in these industries, enabling manufacturers to meet and exceed quality and safety standards.

Designed to meet the strict requirements of international regulations, such as FDA and EHEDG guidelines, Blackmer pump seals offer exceptional sanitary performance. Their smooth surfaces, minimal dead zones, and easy-to-clean designs prevent the accumulation of bacteria, contaminants, and product residues. This helps ensure the integrity and purity of food and beverage products.

The versatility of Blackmer pump seals extends to the diverse range of fluids encountered in food and beverage processes. Whether it's handling viscous syrups, delicate dairy products, or aggressive cleaning solutions, these seals provide reliable and efficient pumping solutions. Furthermore, their robust construction and exceptional sealing capabilities minimize product loss, improve processing efficiency, and reduce maintenance downtime.

Breaking Barriers: Blackmer Pump Seals in Renewable Energy

As the world shifts towards renewable energy sources, innovative pumping technologies are needed to support the rapid growth of this sector. Blackmer pump seals have found their place in renewable energy applications, enabling efficient and reliable fluid transfer and processing in various systems.

In the solar industry, Blackmer pump seals play a crucial role in thermal energy storage systems. By effectively sealing the heat transfer fluid, these seals enhance system performance, ensuring maximum energy collection and storage efficiency. Their resistance to high temperatures and compatibility with heat transfer fluids make them a reliable choice in concentrated solar power plants.

Furthermore, Blackmer pump seals are used in the wind energy sector to facilitate lubrication and cooling in large gearboxes. With their robust construction and ability to handle lubrication fluids in harsh conditions, these seals contribute to the sustained operation and longevity of wind turbines.

Overall, Blackmer pump seal technology is expanding the possibilities and applications in renewable energy, enabling the industry to tackle the challenges of fluid transfer and management efficiently.

Conclusion

The emergence of Blackmer pump seal technology has brought forth a new era of reliability, efficiency, and versatility in pumping solutions. From chemical processing to oil and gas production, and from hygienic applications to renewable energy, Blackmer pump seals are making their mark in various industries. A testament to their performance and durability, these seals provide superior performance, reduce downtime, improve safety, and offer long-term cost savings. As technology continues to advance and new challenges arise, Blackmer pump seals will undoubtedly continue to explore new frontiers, enabling industries to meet their ever-evolving needs.