Customized Applications of Double Cartridge Mechanical Seals in Food and Beverage Industry

Introduction:

The food and beverage industry demands high standards of cleanliness and efficiency in order to deliver safe and reliable products to consumers. In this regard, the use of double cartridge mechanical seals has gained popularity due to their customized applications, providing effective sealing solutions in various processes. These seals offer enhanced protection against leakages, contamination, and product loss, making them an indispensable component in the food and beverage industry. Let's delve into the significance of double cartridge mechanical seals and explore their applications in this ever-evolving sector.

Understanding Double Cartridge Mechanical Seals:

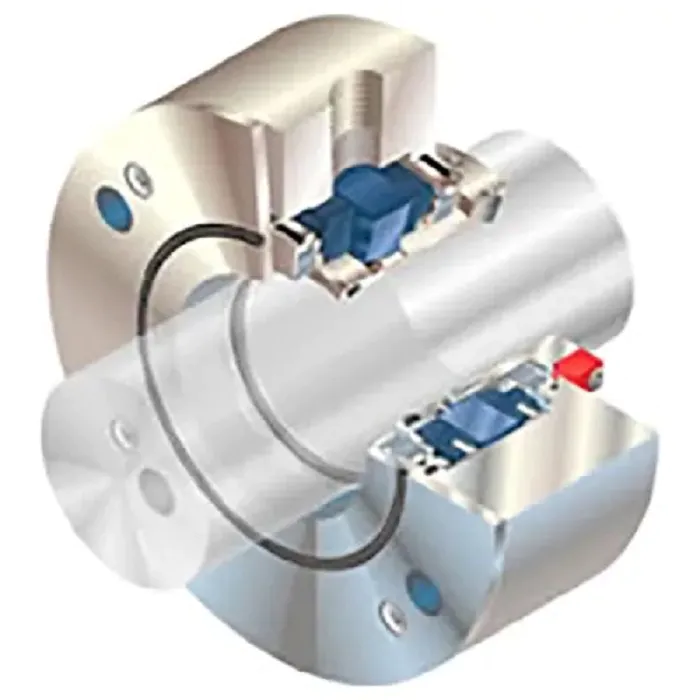

Double Cartridge Mechanical Seals - An Overview

Double cartridge mechanical seals are designed to provide a robust and reliable sealing solution for industrial applications. The key feature that sets these seals apart is their dual arrangement, with two sets of sealing faces that work in tandem to ensure a secure and fail-safe sealing mechanism. This design offers enhanced protection against leaks and enables easy replacement if necessary. The main components of a double cartridge mechanical seal include the seal faces, secondary seals, springs, and hardware. These seals are typically constructed using materials that are compliant with food and beverage industry standards, such as stainless steel and FDA-approved elastomers.

The Advantages of Double Cartridge Mechanical Seals

Double cartridge mechanical seals offer numerous advantages that make them a preferred choice in the food and beverage industry. Firstly, their dual arrangement provides an added layer of protection, minimizing the risk of leaks and ensuring product integrity. In the event of failure or wear, the secondary seal acts as a backup, preventing any contaminants from entering the system. This design also reduces the likelihood of product loss, enhancing process efficiency and reducing downtime for maintenance.

Moreover, double cartridge mechanical seals are designed to withstand high operating pressures and temperatures commonly encountered in food and beverage manufacturing processes. They offer excellent resistance to chemicals, CIP (Clean In Place) solutions, and the cleaning agents used during regular sanitation procedures. This makes them suitable for a wide range of applications, including pumps, mixers, agitators, and other equipment used in the industry.

Applications of Double Cartridge Mechanical Seals in the Food and Beverage Industry:

1. Pump Applications

Pumps play a vital role in various processes within the food and beverage industry, including the transfer of liquids and viscous products such as sauces, juices, and purees. Double cartridge mechanical seals find extensive applications in pump systems, offering reliable sealing solutions for different pump types, including centrifugal, positive displacement, and diaphragm pumps. The dual arrangement of these seals ensures a secure seal, even in high-pressure and high-speed pumping applications.

Furthermore, these seals are designed to prevent product contamination by eliminating dead spots and reducing the potential for bacterial growth. This is especially crucial in the food and beverage industry, where maintaining hygienic conditions is of utmost importance.

2. Mixing and Agitation Applications

In food and beverage production, mixing and agitation processes are essential for blending ingredients, improving product consistency, and achieving homogeneous formulations. Double cartridge mechanical seals are widely used in mixers and agitators to prevent leakage and maintain sterile conditions. They provide effective sealing solutions for shafts, ensuring that no contaminants enter the mixing or agitation vessel.

The versatility of double cartridge mechanical seals allows them to adapt to different shaft sizes and media viscosities. They can withstand the rigorous demands of high-speed mixers and agitators while maintaining optimal sealing performance, thus enhancing the overall productivity and efficiency of these processes.

3. Reactor and Kettle Applications

Reactors and kettles are essential equipment in the food and beverage industry, widely used for cooking, heating, and processing various products. Double cartridge mechanical seals are extensively employed in these applications to prevent leakage and provide a sterile environment for cooking and processing operations.

These seals offer excellent thermal resistance and can withstand the high temperatures and pressures within reactors and kettles. They provide reliable sealing solutions for agitator shafts, ensuring that no contaminants enter the product during processing. The seal's ability to adapt to different shaft sizes and its robust construction make it an ideal choice for these demanding applications.

4. CIP (Clean In Place) Applications

Maintaining cleanliness and hygiene in the food and beverage industry is crucial to ensure the safety and quality of the final products. CIP (Clean In Place) systems are extensively used to clean and sterilize equipment, pipelines, and processing vessels. Double cartridge mechanical seals are designed to withstand the harsh chemicals, high pressures, and temperatures used during CIP procedures, ensuring effective sealing performance even in these challenging conditions.

These seals provide reliable sealing solutions for CIP system components such as pumps, valves, and agitators. They prevent any leaks or contamination during the cleaning process, thus contributing to the overall cleanliness and integrity of the system.

5. Conveyor and Extruder Applications

Conveyor systems and extruders are commonly employed in the food and beverage industry for handling and processing various products. Double cartridge mechanical seals find applications in these systems, ensuring reliable sealing performance and preventing product losses.

These seals offer effective sealing solutions for conveyor shafts and extruder screw shafts, minimizing the risk of leaks and ensuring product integrity throughout the production line. Their ability to withstand the mechanical stresses and high speeds associated with conveyor and extruder operations makes them a suitable choice for these applications.

Conclusion:

Double cartridge mechanical seals play an integral role in the food and beverage industry, providing customized sealing solutions that meet the industry's stringent requirements. With their dual arrangement and robust design, these seals offer enhanced protection against leaks, contamination, and product loss. They find extensive applications in pump systems, mixing and agitation processes, reactors and kettles, CIP applications, and conveyor/extruder systems. By choosing double cartridge mechanical seals for these applications, food and beverage manufacturers can ensure the integrity, cleanliness, and efficiency of their processes, ultimately delivering safe and high-quality products to consumers.