A Comprehensive Overview of Blackmer Pump Seal Design and Functionality

Introductions:

Pumps play a crucial role in various industries, providing the necessary power to transfer fluids from one place to another. Among the many pump options available in the market, Blackmer pumps have gained immense popularity due to their outstanding performance and reliability. A crucial component of any pump is the seal, which prevents leakage and ensures the safe and efficient operation of the pump. In this comprehensive overview, we will delve into the design and functionality of Blackmer pump seals, exploring the features that make them stand out in the industry. Whether you are a maintenance engineer, a pump operator, or simply curious about the inner workings of these essential machines, this article aims to provide you with the knowledge you seek.

The Importance of an Efficient Pump Seal

The seal is a critical element in pump design, responsible for maintaining a fluid-tight environment. Its primary function is to prevent the leakage of the pumped fluid into the surrounding environment. In the case of Blackmer pumps, which are known for their oil-free operation, an efficient seal design is paramount to ensure that no oil leaks into the process fluid. This oil-free feature makes Blackmer pumps suitable for applications in industries such as food processing, pharmaceuticals, and where contamination must be avoided at all costs.

Sealing Mechanisms and Types of Blackmer Pump Seals

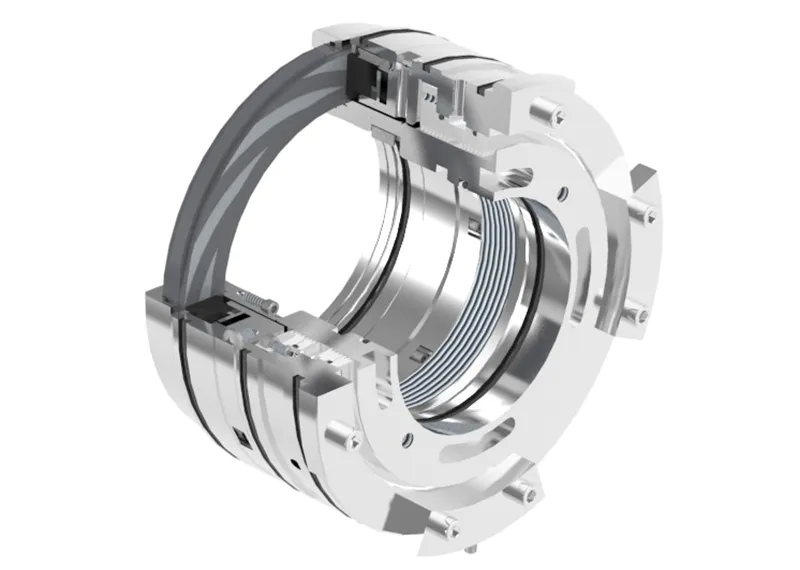

Blackmer pump seals employ various sealing mechanisms, each designed to meet specific requirements and operating conditions. One commonly used sealing mechanism in Blackmer pumps is the mechanical seal. Mechanical seals consist of two main parts, the stationary and rotating faces, which are pressed together to prevent fluid leakage. These seals are highly effective in high-pressure and high-temperature applications and ensure long-lasting performance.

Another type of seal used in Blackmer pumps is the lip seal. Lip seals feature a flexible outer lip that dynamically seals against the rotating shaft, preventing the fluid from escaping. These seals are often used in low-pressure applications and require minimal maintenance due to their simplicity.

Blackmer Pump Seal Materials and Construction

To ensure the longevity and reliability of pump seals, Blackmer utilizes high-quality materials in their manufacturing process. The choice of material is crucial, as it must withstand the chemical properties of the pumped fluid, the operating temperature, and the pressure. Two commonly used materials in Blackmer pump seals are carbon and ceramic.

Carbon is highly resistant to wear and can withstand high temperatures and aggressive chemicals. It is often used as the stationary face in mechanical seals. On the other hand, ceramic seals are known for their hardness and resistance to wear, making them suitable for applications involving abrasive fluids.

Tips for Maintaining and Troubleshooting Blackmer Pump Seals

Regular maintenance and proper troubleshooting techniques can greatly extend the lifespan of Blackmer pump seals and prevent costly repairs. Here are a few tips to help you keep your pump seals in optimal condition:

1. Monitor Seal Leakage: Regularly inspect the pump for any signs of seal leakage. Leakage can indicate seal damage or misalignment and should be addressed promptly to prevent further issues.

2. Maintain Proper Lubrication: Ensure that the seal faces receive sufficient lubrication to reduce friction and heat generation. Consult the manufacturer's guidelines for recommended lubricants and lubrication intervals.

3. Check for Shaft Runout: Excessive shaft runout can cause premature wear of the seal faces. Use a dial indicator to measure the shaft runout and take corrective measures if necessary.

4. Avoid Dry Running: Operating the pump without any liquid can lead to seal failure due to excessive heat generation. Always ensure that the pump is properly primed before starting.

5. Follow Proper Installation Procedures: Improper installation can damage the seal and compromise its effectiveness. Follow the manufacturer's instructions for correct installation techniques, including proper torquing of the seal components.

Summary

In conclusion, Blackmer pump seals are a vital component in ensuring the safe and efficient operation of pumps in various industries. Their design, materials, and sealing mechanisms are carefully engineered to withstand the demanding conditions encountered in high-pressure, high-temperature, and abrasive fluid applications. By understanding the importance of an efficient pump seal and following proper maintenance and troubleshooting techniques, pump operators can prolong the lifespan of their Blackmer pump seals and minimize downtime.