Quality inspection process of mechanical seal manufacturers

by:Lepu Seal

2022-08-23

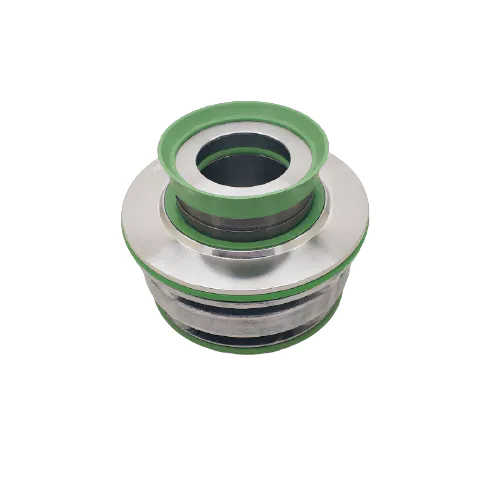

The mechanical seal is a sealing device composed of two sealing elements (static ring and moving ring) perpendicular to the shaft, smooth and flat surfaces that fit each other and rotate relative to each other. It relies on the pressure of the sealing medium to generate an appropriate pressing force on the contact surface (end surface) of the rotating dynamic ring and the static ring, so that the two end surfaces are tightly combined, and a very thin liquid film is maintained between the end surfaces to achieve sealing. purpose. This layer of liquid film has hydrodynamic pressure and static pressure, which play the role of lubricating and balancing force.

1. Cleaning and inspection of mechanical seals

1) The working principle of the mechanical seal requires that there are no impurities inside the mechanical seal. Before assembling the mechanical seal, clean the moving ring, static ring, shaft sleeve and other components.

2) Check whether there are scratches, cracks and other defects on the surface of the dynamic and static rings. The existence of these defects will cause serious leakage of the mechanical seal. If conditions permit, special tools can be used to check whether the sealing surface is flat. If the sealing surface is not flat, the pressure water will enter the sealing surface of the dynamic and static rings of the mechanical seal after assembly, separate the dynamic and static rings, and the mechanical seal will fail. If necessary, tooling can be made for hydrostatic test before assembly.

3) Check whether the dynamic and static ring seat has defects that affect the sealing. For example, whether there are defects in the mating surface of the dynamic and static ring seat and the dynamic and static ring sealing ring.

4) Check whether the mechanical seal compensation spring is damaged and deformed, and whether the stubborn coefficient changes.

5) Check the sealing sleeve for defects such as burrs and grooves.

6) Clean and check all sealing rubber rings for cracks, pores and other defects, and measure whether the diameter of the rubber ring is within the tolerance range.

7) The mechanical seal with the pumping mechanism should also check whether the screw of the screw pump has defects such as cracks and broken wires.

2. Technical dimension check of mechanical seal assembly

1) Measure the size of the sealing surface of the dynamic and static rings. This data is used to verify the radial width of the dynamic and static rings. When different friction materials are used, the radial width of the friction surface of the hard material should be 1-3mm larger than that of the soft material, otherwise the edges and corners of the end face of the hard material will be easily embedded in the end face of the soft material. go up.

2) Check the clearance between the dynamic and static rings and the shaft or the shaft sleeve. The inner diameter of the static ring is generally 1-2mm larger than the shaft diameter. For the dynamic ring, in order to ensure the floating, the inner diameter is 0.5-1mm larger than the shaft diameter to compensate for the vibration of the shaft. and deflection, but the gap should not be too large, otherwise the moving ring seal will be stuck and the mechanical seal function will be damaged.

3) Check the tightness of the mechanical seal. The mechanical seal tightening force we usually talk about is the specific pressure of the end face, and the specific pressure of the end face should be appropriate. If it is too large, the friction surface of the mechanical seal will heat up, accelerate the wear of the end face, and increase the friction power; if it is too small, it is easy to leak. The specific pressure of the end face is determined during the design of the mechanical seal, and we can only determine it by measuring the tightness of the mechanical seal during assembly. The usual measurement method is to measure the vertical distance from the installed static ring end face to the gland end face, and then measure the vertical distance from the movable ring end face to the gland end face. The difference between the two is the tightness of the mechanical seal.

4) Measure whether the length of the compensation spring has changed. Changes in spring performance will directly affect the specific pressure of the mechanical seal end face. In general, the length of the spring will be shortened after long-term operation, and the mechanical seal of the compensation spring on the moving ring will also be deformed due to centrifugal force.

5) Measure the length of the anti-rotation pin of the static ring and the depth of the pin hole to prevent the static ring from being assembled in place if the pin is too long. This condition can damage the mechanical seal.

3. Grinding of the end faces of the moving and stationary rings

1) After the moving ring is removed, it is ground, rough grinding first, then fine grinding, and polishing can be carried out if conditions permit.

2) When rough grinding, use abrasives with a particle size of 80-160#, and grind away the processing marks first. Then it can be used for fine grinding with abrasives above 160# to make the finish meet the design requirements. Carbide or ceramic moving rings need to be polished with a polishing machine after fine grinding. The strength of the polishing machine can be selected from M28~M5 boron carbide. A mirror finish is achieved after polishing. The ceramic ring can be polished with chrome oxide after fine grinding with M5 agate powder.

3) The static ring of graphite filled PTFE can be finely ground with kerosene, gasoline or water due to its soft material, without adding abrasives. It can also be self-developed during the running-in process, so the finish requirements are not too high.

4) Grinding method, if there is a grinder, you can grind it on the grinder, and if there is no grinder, you can use the figure-8 manual grinding method on the flat glass.

4. Bushing inspection

1) Check the rust and wear after removing the shaft sleeve. If the rust or wear is relatively minor, it can be polished with fine sandpaper and reused. If the rust or wear is serious, the method of electroplating after processing can be used or a new shaft sleeve can be used. .

5. Seal the o-ring

1) After a period of use, the sealing ring loses its elasticity or ages in most cases, and generally needs to be replaced with a new ring.

6. Spring

1) If the spring is not seriously corroded and can maintain its original elasticity, it is not necessary to replace it. If the corrosion is severe or the elasticity is greatly reduced, a new spring needs to be replaced.

2) For mechanical seals with assembled boxes, clean the box and check whether the grooves are worn or deformed, so as to be corrected and repaired, re-grooved or replaced.

3) After the mechanical sealing element is repaired, re-assemble it, and also perform a pressure test after assembly, and then put it into normal operation.

Custom message