Assembly method of cartridge mechanical seal

by:Lepu Seal

2022-08-31

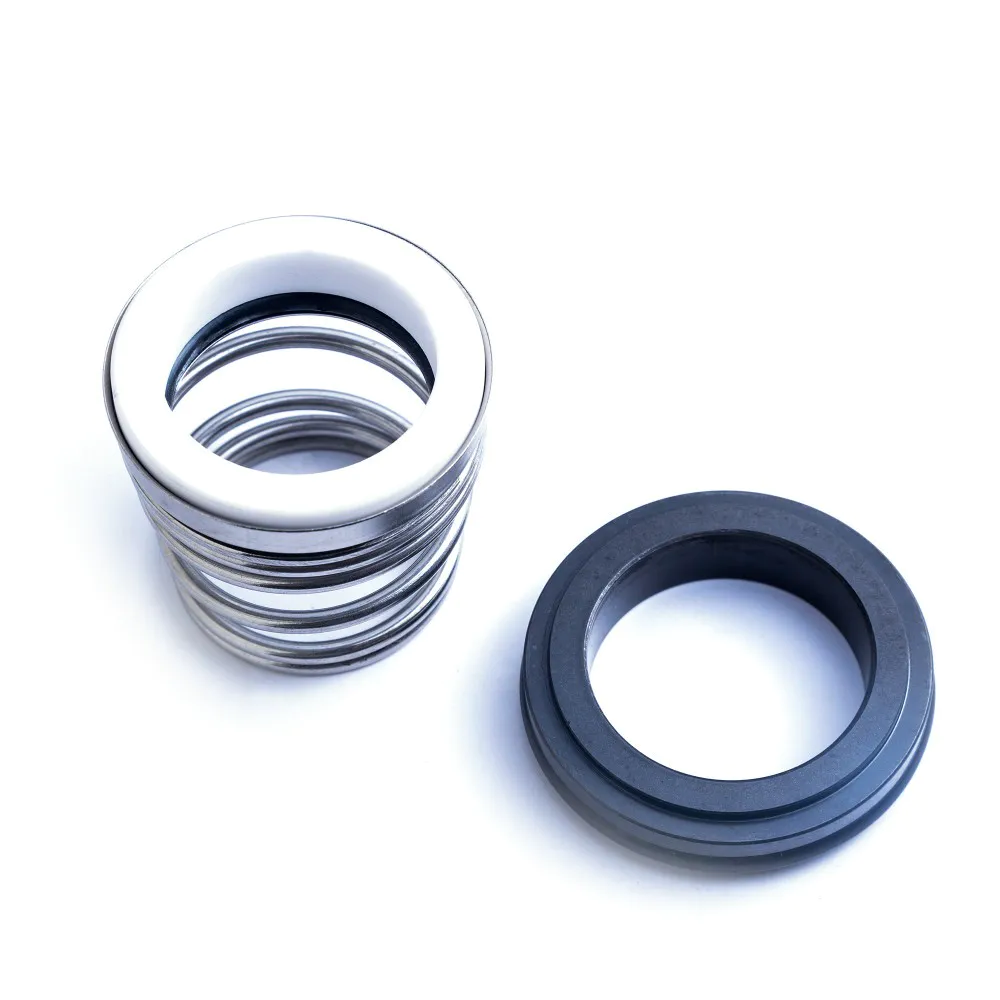

Assembly method of cartridge mechanical seal

(1) Assembly of gland and bellows The gland and bellows are connected with 6-12 bolts, and there are gaskets between them to prevent medium leakage. (2) Hard ring positioning First, fix the fixing ring on the shaft sleeve positioning counterbore, then put the gland and bellows components in, so that the Grundfos mechanical seal and the fixing ring are on top, and put the hard ring and wedge ring And the rotating seat ring, after confirming the position of the rotating seat ring, slightly tighten the set screw of the rotating ring, the rotating ring and the hard ring are connected with screws, and take out the fixing ring, the gland, and the bellows assembly. (3) When the end face is aligned and the rotating seat ring and the hard ring are connected to the shaft sleeve, the mechanical seal must be imported to maintain the verticality of the end face. Generally, the runout of the end face is guaranteed to be less than 0.05mm. On the assembly platform, after tightening the set screw on the rotating seat ring, use the dial indicator to align while tightening the screw connecting the rotating seat ring and the hard cartridge mechanical seal ring. to ensure the verticality of the end face. (4) Adjustment of compression amount The compression amount of the cartridge bellows mechanical seal is reflected in the thickness of the positioning block. However, some special users want different compression amounts, which can be adjusted according to the following methods: 45, 55 series seals, when determining the position of the hard ring, place the water blocking aluminum plate on the gland on the concave groove of the shaft sleeve matched with the positioning block (positioning fork). On the outer edge of the groove, the rotating seat ring and the hard ring are tightly attached to the graphite ring and fixed on the shaft sleeve. After placing the positioning plate, the compression amount is the designed compression amount, which is the thickness of the fork plate. Changing the compression amount can move the hard ring back and forth on the sleeve, and the movement amount is the changed compression amount. For 60, 70, 85, 90, 120 series seals, the position of the hard ring is the position when the gland water retaining aluminum plate is attached to the fixed ring, and the compression amount is the thickness of the positioning block. If the compression amount is changed, the hard ring can be moved back and forth on the shaft sleeve, and the movement amount is the change amount of the compression amount.

(1) Assembly of gland and bellows The gland and bellows are connected with 6-12 bolts, and there are gaskets between them to prevent medium leakage. (2) Hard ring positioning First, fix the fixing ring on the shaft sleeve positioning counterbore, then put the gland and bellows components in, so that the Grundfos mechanical seal and the fixing ring are on top, and put the hard ring and wedge ring And the rotating seat ring, after confirming the position of the rotating seat ring, slightly tighten the set screw of the rotating ring, the rotating ring and the hard ring are connected with screws, and take out the fixing ring, the gland, and the bellows assembly. (3) When the end face is aligned and the rotating seat ring and the hard ring are connected to the shaft sleeve, the mechanical seal must be imported to maintain the verticality of the end face. Generally, the runout of the end face is guaranteed to be less than 0.05mm. On the assembly platform, after tightening the set screw on the rotating seat ring, use the dial indicator to align while tightening the screw connecting the rotating seat ring and the hard cartridge mechanical seal ring. to ensure the verticality of the end face. (4) Adjustment of compression amount The compression amount of the cartridge bellows mechanical seal is reflected in the thickness of the positioning block. However, some special users want different compression amounts, which can be adjusted according to the following methods: 45, 55 series seals, when determining the position of the hard ring, place the water blocking aluminum plate on the gland on the concave groove of the shaft sleeve matched with the positioning block (positioning fork). On the outer edge of the groove, the rotating seat ring and the hard ring are tightly attached to the graphite ring and fixed on the shaft sleeve. After placing the positioning plate, the compression amount is the designed compression amount, which is the thickness of the fork plate. Changing the compression amount can move the hard ring back and forth on the sleeve, and the movement amount is the changed compression amount. For 60, 70, 85, 90, 120 series seals, the position of the hard ring is the position when the gland water retaining aluminum plate is attached to the fixed ring, and the compression amount is the thickness of the positioning block. If the compression amount is changed, the hard ring can be moved back and forth on the shaft sleeve, and the movement amount is the change amount of the compression amount.

Custom message