The Role of Tungsten Carbide Seal Rings in Power Generation and Utilities

Introduction:

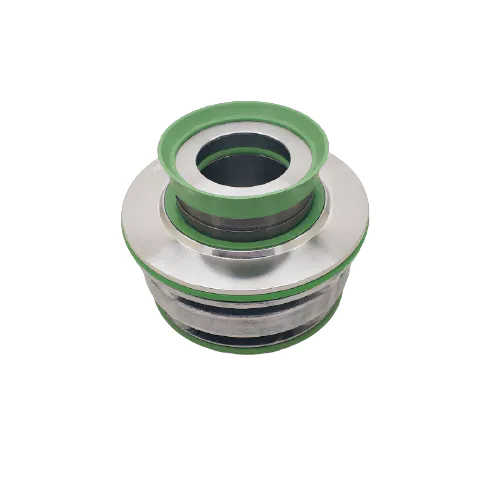

The power generation and utilities industry plays a crucial role in meeting the ever-increasing energy demands of our modern world. With the growing need for efficient and reliable machinery, the importance of using high-quality components cannot be overstated. Tungsten carbide seal rings have emerged as a vital component in the power generation and utilities sector, ensuring optimal performance and longevity of equipment. These robust and durable seal rings offer exceptional resistance to wear and corrosion, making them indispensable in various applications. Let us delve deeper into the role of tungsten carbide seal rings and their applications in this industry.

Enhancing Equipment Performance with Tungsten Carbide Seal Rings

Tungsten carbide seal rings are extensively utilized in power generation and utilities due to their exceptional mechanical properties. These rings are widely employed in centrifugal pumps, turbines, compressors, and valves, contributing to the seamless operation of these critical components. The unique hardness of tungsten carbide seal rings makes them ideal for use in high-pressure and high-temperature environments, ensuring reliable sealing and preventing leakages. Furthermore, their chemical inertness and low coefficient of friction enable efficient transfer of fluids while reducing energy losses, thereby enhancing overall equipment performance.

Pump Applications in Power Generation

In the power generation industry, pumps play a crucial role in circulating fluids throughout the system. Tungsten carbide seal rings find extensive application in pump systems, enhancing their efficiency and reliability. These seal rings effectively seal the rotating shaft, preventing fluid leakage and subsequent energy wastage. Additionally, tungsten carbide seal rings exhibit excellent resistance to abrasive fluids, making them ideal for handling challenging environments. Their ability to withstand high speeds and pressures ensures smooth and uninterrupted pump operation, reducing maintenance downtime and optimizing energy consumption.

Turbine and Compressor Applications

Turbines and compressors are vital components in power generation and utilities, and their efficient operation is critical for uninterrupted power supply. Tungsten carbide seal rings play a pivotal role in ensuring the reliability and longevity of these machines. In turbines, seal rings are used to seal the shaft and prevent steam or gas leakage. With their exceptional resistance to thermal and mechanical stresses, tungsten carbide seals create a robust barrier, allowing turbines to operate at high speeds and temperatures without compromising efficiency. Similarly, in compressors, these seal rings help maintain optimal compression ratios, reducing energy losses and enhancing overall efficiency.

Valve Applications for Fluid Control

Fluid control is of utmost importance in power generation and utilities. Valves are used to regulate the flow and pressure of fluids in various stages of the process. Tungsten carbide seal rings are critical components in valves, ensuring a tight seal and preventing leaks. These seal rings offer excellent resistance to both erosive and corrosive fluids, making them ideal for valves that handle aggressive media. Their ability to withstand high pressures and temperatures allows valves to operate efficiently without compromising safety and performance. Moreover, the exceptional hardness of tungsten carbide seal rings ensures long-lasting sealing capabilities, minimizing maintenance and downtime.

Corrosion and Wear Resistance

Power generation and utility applications often involve harsh operating conditions that subject equipment to corrosion and wear. Tungsten carbide seal rings are renowned for their outstanding resistance to corrosion and wear, making them an ideal choice for such environments. These seal rings exhibit excellent chemical inertness and hardness, ensuring prolonged service life even in aggressive fluid conditions. With their superior resistance to abrasive particles, they prevent erosion of surfaces, reducing the need for frequent replacement. This characteristic significantly contributes to cost savings and improves the reliability and performance of equipment throughout their operational lifespan.

Summary:

In the power generation and utilities industry, the role of tungsten carbide seal rings cannot be overlooked. These high-performance components are essential for ensuring optimal equipment performance, reducing maintenance downtime, and enhancing energy efficiency. From pumps to turbines, compressors to valves, tungsten carbide seal rings provide reliable sealing and resistance to wear and corrosion. With their exceptional properties and durability, these seal rings offer significant benefits to the power generation and utilities sector. Investing in high-quality tungsten carbide seal rings is a prudent choice for industries seeking reliable and efficient machinery for meeting the ever-increasing energy demands of the modern world.