The Role of Grundfos Pump Mechanical Seals in Power Generation and Utilities

Imagine a world without electricity. It is almost impossible to fathom, considering our reliance on it for nearly every aspect of our lives. Power generation and utilities play a pivotal role in keeping our cities lit up, our homes warm, and our industries running smoothly. Behind the scenes of this vast system, there are countless components working together to ensure the reliable and efficient production and distribution of electricity. One such crucial component is the Grundfos pump mechanical seal, which plays a vital role in power generation and utilities.

In this article, we will explore the significance of Grundfos pump mechanical seals in this industry, and how they contribute to the overall reliability and efficiency of power generation and utilities. We will delve into the functionalities, applications, and benefits of these seals, highlighting their importance in various processes. So, let's dive in and uncover the inner workings of Grundfos pump mechanical seals.

The Fundamentals of Grundfos Pump Mechanical Seals

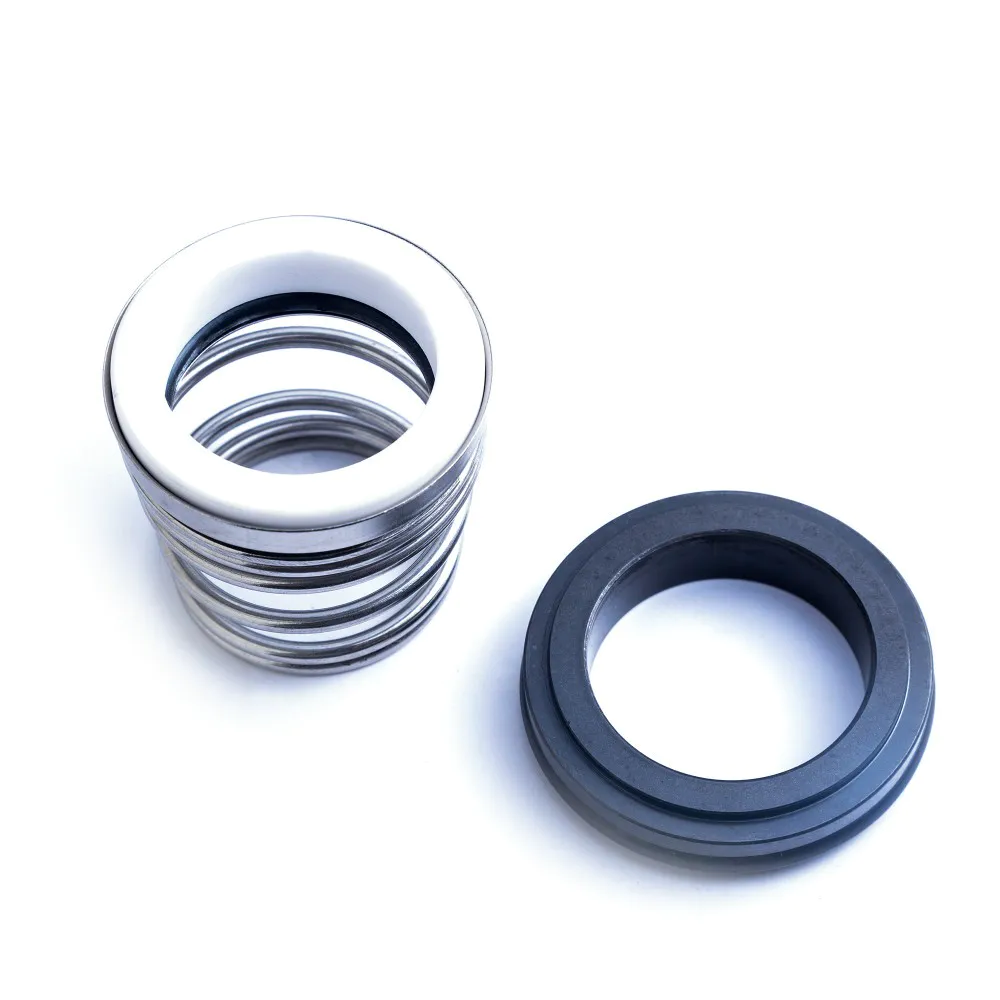

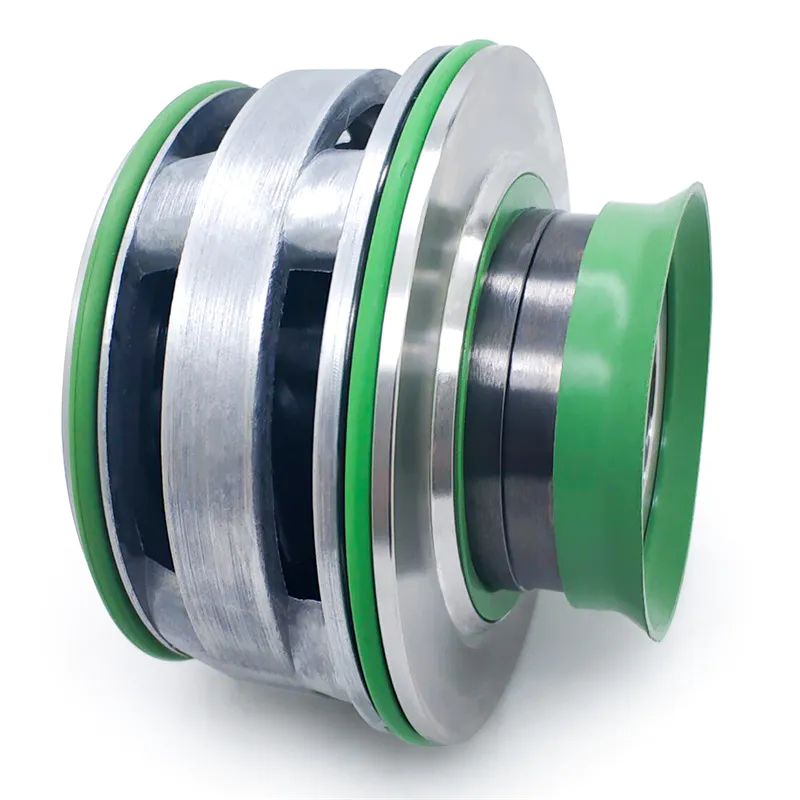

Mechanical seals are devices that prevent fluid leakage from a pump or a rotating machine. They are typically used to seal spaces between stationary and rotating parts in order to maintain the integrity of the system. Grundfos pump mechanical seals are specifically designed by Grundfos, a world-leading pump manufacturer, to provide superior sealing performance in power generation and utilities applications.

These seals are meticulously engineered to withstand high pressures, resist corrosion, and maintain their effectiveness over an extended lifespan. By effectively sealing the pump, they prevent leakage and the potential for equipment damage, ensuring the smooth operation of power generation and utilities systems.

Applications in Power Generation

Power generation encompasses a wide range of processes, including thermal power plants, hydroelectric power plants, and nuclear power plants. In each of these applications, Grundfos pump mechanical seals provide reliable sealing solutions that contribute to the overall efficiency and stability of the system.

In thermal power plants, mechanical seals are used in boiler feed pumps, condensate pumps, and cooling water pumps. These pumps are responsible for circulating water, steam, and condensate throughout the system. The mechanical seals in these pumps prevent steam and water leakage, ensuring proper functioning and minimizing energy losses.

Similarly, in hydroelectric power plants, Grundfos pump mechanical seals are vital components in the turbine water supply pumps, cooling water pumps, and drainage pumps. These seals ensure efficient water circulation, preventing any seepage or leakage that could lead to equipment failure or reduced output.

Nuclear power plants also heavily rely on Grundfos pump mechanical seals to ensure the safe and efficient operation of coolant pumps, feedwater pumps, and emergency cooling pumps. Given the nature of nuclear power plants, where any failure poses significant risks, the reliability and performance of these seals are of utmost importance to maintain the integrity of the system.

Role in Utilities

Utilities, on the other hand, refer to the network that connects power generation facilities to consumers. This includes transmission lines, distribution stations, and transformers, among other components. Although not directly involved in power production, these elements are crucial for the efficient and reliable distribution of electricity.

Grundfos pump mechanical seals find applications in the utilities sector that contribute to the proper functioning of this vast network. They are used in substation transformers, which play a crucial role in voltage conversion and distribution. By sealing the pump in these transformers, mechanical seals ensure the safety and efficiency of the overall system.

Mechanical seals are also employed in cooling water pumps used in electrical substations to dissipate the heat generated by various electrical components. By effectively sealing these pumps, Grundfos pump mechanical seals prevent water leakage and maintain optimal cooling performance, ensuring the longevity and efficiency of these critical systems.

The Benefits of Grundfos Pump Mechanical Seals

Now that we understand the various applications of Grundfos pump mechanical seals in power generation and utilities, let's explore the benefits they offer:

1. Reliability: Grundfos pump mechanical seals are designed to withstand demanding environments, ensuring reliable operation even under extreme conditions. This reliability translates into reduced downtime, increased productivity, and lower maintenance costs.

2. Efficiency: By preventing fluid leakage, these seals optimize the efficiency of pumps and other equipment. This, in turn, reduces energy consumption, leading to cost savings and environmental benefits.

3. Durability: Grundfos pump mechanical seals are built to withstand the wear and tear of continuous operation. They are resistant to corrosion, erosion, and abrasion, enhancing their longevity and reducing the need for frequent replacements.

4. Environmental Compliance: These seals meet stringent environmental regulations by minimizing leakage, thus preventing potential contamination of the surroundings. This makes them an ideal choice for environmentally conscious power generation and utilities facilities.

5. Maintainability: Grundfos pump mechanical seals are designed for easy installation, disassembly, and maintenance. This ensures that any necessary repairs or replacements can be performed efficiently, minimizing disruptions to the overall system.

In summary, Grundfos pump mechanical seals are essential components in power generation and utilities systems. They play a crucial role in preventing fluid leakage, ensuring the reliable and efficient operation of various pumps and equipment. With their reliability, efficiency, durability, environmental compliance, and maintainability, these seals have become a preferred choice in the industry.

As we continue to rely on electricity to power our world and drive progress, Grundfos pump mechanical seals will remain a fundamental part of the intricate machinery that makes it all possible. Their ongoing innovation and commitment to quality contribute to the continuous improvement of power generation and utilities systems, paving the way for a more sustainable and efficient future.