The Advantages of Cartridge Seals in Pump Applications: A Comprehensive Guide

The Advantages of Cartridge Seals in Pump Applications: A Comprehensive Guide

Introduction

Pumps are essential devices used in various industrial and commercial applications to move fluids from one place to another. A key component of pumps is the sealing mechanism, which prevents leakage and ensures the efficient operation of the pump. Traditional gland packing seals have been commonly used for this purpose, but cartridge seals have gained popularity in recent years due to their numerous advantages. In this comprehensive guide, we will explore the advantages of cartridge seals in pump applications and why they are becoming the preferred choice for many industries.

I. Understanding Cartridge Seals

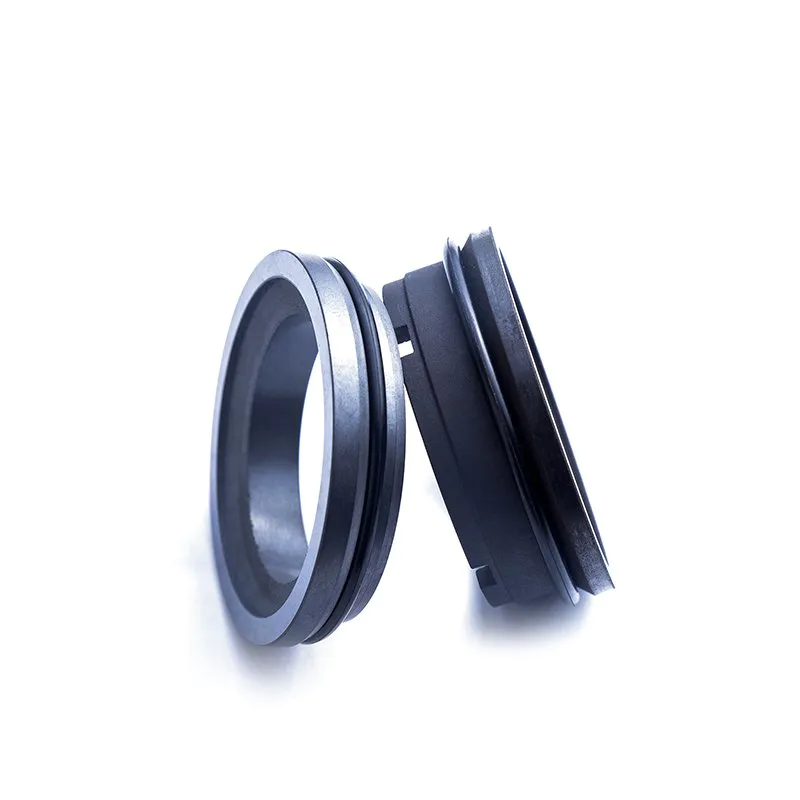

Cartridge seals are self-contained sealing units that consist of a rotating face, stationary face, and secondary seal. These pre-assembled units are designed to be easily installed in pumps without the need for additional parts or adjustments. Unlike traditional gland packing seals, which require frequent maintenance and adjustment, cartridge seals offer a more convenient and reliable sealing solution.

II. Enhanced Seal Performance

One of the primary advantages of cartridge seals is their enhanced sealing performance. The pre-assembled design of these seals ensures optimal alignment of the sealing faces, minimizing the risk of leakage. The precision engineering and high-quality materials used in cartridge seals further enhance their performance, providing a leak-free and durable sealing solution.

III. Reduced Downtime and Maintenance

Cartridge seals are known for their ease of installation and reduced downtime compared to gland packing seals. With gland packing seals, regular maintenance and adjustments are necessary to maintain their sealing efficiency. This involves stopping the pump, disassembling the housing, and replacing or adjusting the packing rings. In contrast, cartridge seals can be quickly replaced without the need for extensive disassembly, significantly reducing downtime and maintenance costs.

IV. Environmental Friendliness

In today's environmentally conscious world, reducing fluid leakage and minimizing environmental impact is crucial. Cartridge seals excel in this aspect by significantly reducing or eliminating leakage altogether. The advanced sealing technology used in cartridge seals ensures a tight and reliable seal, preventing harmful fluid leakage into the environment. This not only helps in complying with environmental regulations but also contributes to a safer and cleaner workplace.

V. Versatility and Compatibility

Cartridge seals are designed to be versatile and compatible with various pump applications. They can be used in centrifugal pumps, positive displacement pumps, and other types of pumps. Furthermore, cartridge seals are available in a wide range of designs, materials, and configurations to suit specific application requirements. This versatility ensures that cartridge seals can be used in diverse industries, including chemical, oil and gas, pharmaceutical, water treatment, and many more.

VI. Improved Safety

Safety is of paramount importance in any industrial setting, and cartridge seals contribute to a safer working environment. The robust construction and reliable sealing performance of cartridge seals minimize the risk of fluid leakage, which can lead to accidents, equipment damage, and injuries. By choosing cartridge seals for pump applications, industrial operators can prioritize the safety of their employees and protect valuable assets.

VII. Cost-Effective Solution

While cartridge seals may have a slightly higher upfront cost compared to gland packing seals, they prove to be a cost-effective solution in the long run. The reduced maintenance requirements, increased reliability, and extended service life of cartridge seals result in significant cost savings over time. The minimal maintenance and decreased downtime also translate into improved productivity and operational efficiency, making cartridge seals an economically advantageous choice.

Conclusion

Cartridge seals offer numerous advantages over traditional gland packing seals in pump applications. Their enhanced sealing performance, reduced downtime and maintenance, environmental friendliness, versatility, improved safety, and cost-effectiveness make them a compelling choice for various industries. By investing in cartridge seals, industrial operators can ensure efficient and reliable pump operation, minimize fluid leakage, and ultimately achieve higher productivity and profitability.