Single Spring Mechanical Seals: A Reliable Sealing Choice

Single Spring Mechanical Seals: A Reliable Sealing Choice

Introduction

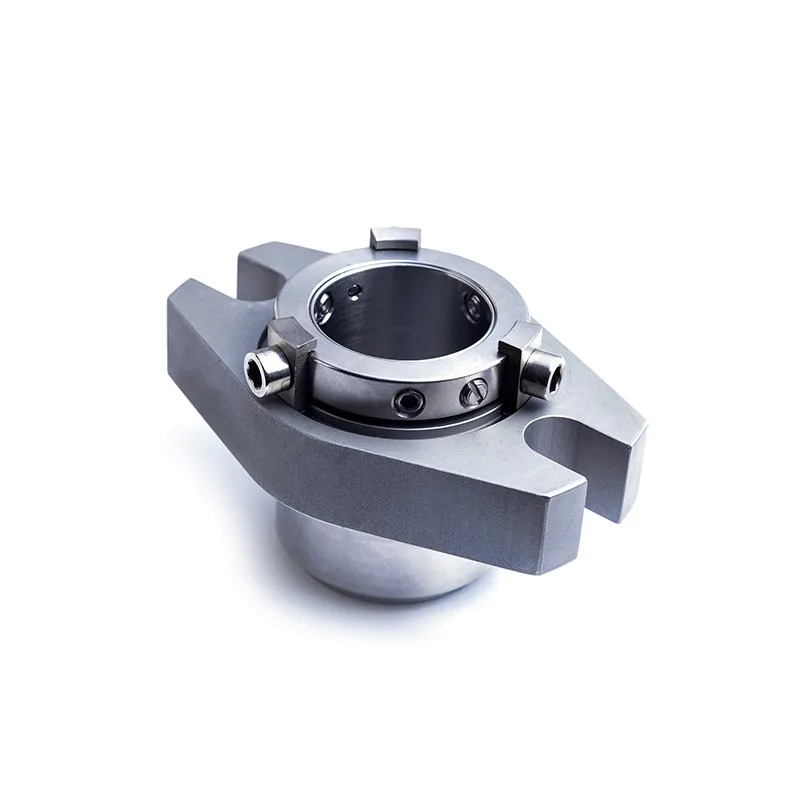

Mechanical seals play a vital role in preventing leakage in various industries, from manufacturing to oil and gas. These sealing devices help ensure that fluids and gases remain contained within their designated systems. Among the different types of mechanical seals available, single spring mechanical seals have gained popularity due to their reliability and efficiency. This article will explore the features, benefits, and applications of single spring mechanical seals, highlighting why they are a dependable choice for sealing applications across industries.

Benefits of Single Spring Mechanical Seals

1. Enhanced Reliability

The first benefit of single spring mechanical seals is their enhanced reliability. These seals are designed with a single coil spring, which provides consistent pressure on the seal faces. This design leads to improved sealing performance and reduces the risk of leakage. The simplicity of these seals also minimizes the chances of mechanical failure, resulting in a more reliable sealing solution.

2. Operational Efficiency

Single spring mechanical seals are known for their operational efficiency. The use of a single spring allows for easier installation and maintenance. These seals have fewer components compared to other types of mechanical seals, simplifying the assembly process. Additionally, the reduced number of parts decreases the likelihood of assembly errors and subsequent seal failures. The operational efficiency of single spring mechanical seals translates into time and cost savings for industries utilizing these sealing solutions.

3. Versatility in Sealing Applications

Another advantage of single spring mechanical seals is their versatility in sealing applications. These seals are suitable for a wide range of industries, including automotive, pharmaceutical, chemical, and food processing. Whether the requirement is to seal corrosive liquids, abrasive slurries, or high-temperature gases, single spring mechanical seals can handle a variety of sealing tasks, making them a reliable choice for many different applications.

4. Low Friction and Wear

Single spring mechanical seals are specifically designed to minimize friction and wear. The materials used in these seals, such as carbon and ceramics, have excellent resistance to wear and tear. The single spring design ensures even distribution of pressure, reducing the chances of localized wear. The low friction properties of single spring mechanical seals not only extend their lifespan but also contribute to improved energy efficiency in the systems they are used in.

5. Cost-Effective Solution

Cost-effectiveness is a significant factor in any industry, and single spring mechanical seals excel in this aspect. These seals offer a reliable and durable sealing solution at an affordable price point. With their reduced maintenance requirements and long-lasting performance, single spring mechanical seals provide a cost-effective sealing choice for businesses looking to optimize their operational budgets.

Applications of Single Spring Mechanical Seals

1. Pumps and Mixers

Pumps and mixers are commonly found in various industrial processes. Single spring mechanical seals are frequently employed in these applications to ensure reliable sealing. Whether it is a centrifugal pump, rotary mixer, or a positive displacement pump, these seals can effectively prevent leakage and contamination, allowing for smooth operation and enhanced productivity.

2. Compressors and Turbines

Compressors and turbines often operate under high-pressure conditions, making reliable sealing crucial to prevent leaks. Single spring mechanical seals excel in such environments, providing effective sealing for air compressors, gas compressors, and steam turbines. Their robust design and ability to withstand extreme pressures make them a preferred choice in these applications.

3. Agitators and Reactors

In the chemical and pharmaceutical industries, agitators and reactors are used for various mixing and reaction processes. Single spring mechanical seals are well-suited for these applications, where hazardous or corrosive substances are commonly handled. The reliable sealing provided by these seals ensures safe and efficient operation while maintaining process integrity.

4. Water Treatment Systems

Water treatment systems require reliable sealing to prevent leakages and contamination. Single spring mechanical seals are widely used in water treatment applications, such as sewage treatment plants, desalination plants, and industrial water processing facilities. Their ability to withstand corrosive environments and maintain sealing integrity makes them an ideal choice for these critical applications.

5. Food and Beverage Industry

The food and beverage industry has stringent hygiene and safety requirements. Single spring mechanical seals are widely accepted in this industry due to their materials' compatibility with food-grade standards and their ability to prevent leakage during processing and packaging. From pumps and mixers to filling machines and conveyor systems, these seals ensure a sanitary and leak-free production environment.

Conclusion

Single spring mechanical seals offer numerous benefits that make them a reliable choice for sealing applications across various industries. Their enhanced reliability, operational efficiency, versatility, low friction, and wear resistance make them highly desirable sealing solutions. In addition, their cost-effectiveness further adds to their appeal. Whether used in pumps, mixers, compressors, agitators, or water treatment systems, single spring mechanical seals consistently deliver optimal sealing performance, providing leak-free operation and ensuring the integrity of industrial processes.