Labyrinth Seals in Subsea Equipment: Surviving the Depths

Labyrinth Seals in Subsea Equipment: Surviving the Depths

Introduction:

Exploring the deep sea has always been a challenge for scientists and engineers alike. As we delve into the vast ocean floors, subsea equipment faces extreme conditions and high pressure, making it crucial to ensure the integrity and reliability of these systems. One vital component that enables these machines to withstand the depths is the labyrinth seal. This article will delve into the intricacies of labyrinth seals, their importance in subsea equipment, their working principles, various applications, and emerging technologies.

1. The Significance of Labyrinth Seals:

The labyrinth seal, a type of non-contact seal, plays a vital role in subsea equipment by preventing the ingress of harmful substances such as seawater, mud, and sand into delicate machinery. It provides a barrier between the internal components and the external environment, maintaining a controlled atmosphere for efficient and uninterrupted operation. Without labyrinth seals, subsea equipment would be vulnerable to catastrophic failures caused by corrosion, erosion, and fluid contamination.

2. Working Principles:

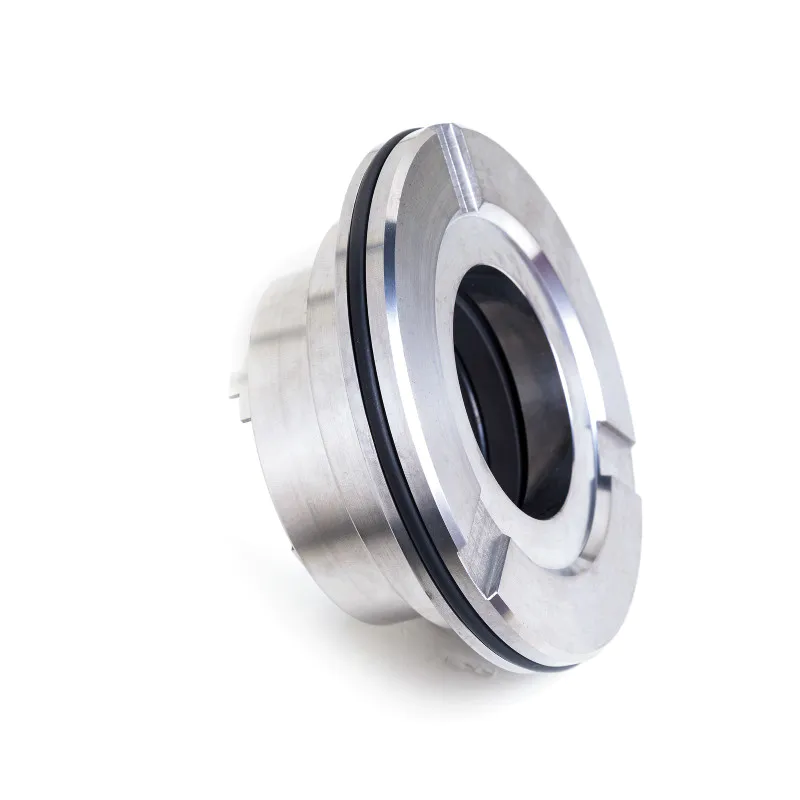

Labyrinth seals work on a simple yet effective principle. They consist of a series of interlocking ridges and grooves, creating a tortuous and maze-like path for any potential leakage. When assembled, these ridges create a tighter and longer path, forcing any escaping fluid to flow through multiple turns before reaching the outside. This design ensures that pressure loss is minimal, providing an efficient solution for sealing subsea equipment.

3. Applications in Subsea Equipment:

Labyrinth seals find wide-ranging applications in subsea equipment due to their robustness and reliability. They are commonly used in submersible pumps, underwater turbines, offshore drilling equipment, and remotely operated vehicles (ROVs). These seals not only protect the machinery from external elements but also ensure efficient power transmission by reducing energy losses caused by leakage.

4. Enhanced Materials and Coatings:

As subsea equipment operates under harsh conditions, labyrinth seals must be built to withstand extreme pressures, temperature variations, and corrosive environments. Advanced materials and specialized coatings have revolutionized the seal manufacturing industry, enabling seals to endure the depths for extended periods. Materials such as carbon fiber-reinforced polymers and alloys like stainless steel provide exceptional strength and corrosion resistance, ensuring prolonged seal life.

5. Sealing Solutions for Emerging Technologies:

With the rise of emerging subsea technologies, such as deep-sea mining and offshore wind farms, labyrinth seals face new challenges and demands. Sealing solutions for these applications require improved reliability, reduced maintenance, and enhanced performance. Researchers are exploring innovative materials and geometries to optimize labyrinth seals for specific subsea applications, maximizing system performance and minimizing environmental impact.

6. Advancements in Sealing Technology:

The progress in sealing technology continues to drive advancements in labyrinth seals for subsea equipment. One significant development is the integration of condition monitoring systems within the seals themselves. This allows for real-time monitoring of seal performance, enabling proactive maintenance and reducing potential downtime. Additionally, the advent of 3D printing has opened new avenues for the rapid prototyping and customization of labyrinth seals, further enhancing their adaptability to unique subsea environments.

Conclusion:

In conclusion, labyrinth seals are a critical component in subsea equipment, serving as an indispensable defense against the extreme conditions encountered in the deep sea. Through their intricate design and robust materials, they protect subsea machinery from the corrosive effects of seawater, erosion, and fluid contamination. As emerging subsea technologies continue to push boundaries, labyrinth seals must evolve to withstand new challenges. The constant advancements in sealing technology will ensure the continued exploration of the depths, enabling researchers and engineers to unlock the mysteries of the underwater world.