Installation and Maintenance Best Practices for Single Cartridge Seals

Introduction

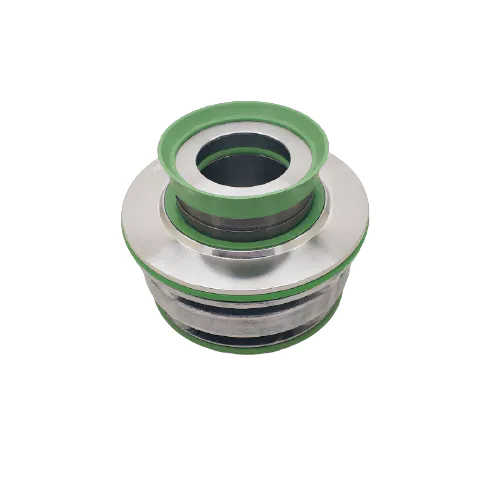

Single cartridge seals are essential components in various industrial applications, providing efficient sealing solutions to prevent leakage and ensure the smooth operation of rotating equipment. However, to maximize the performance and lifespan of these seals, proper installation and maintenance practices are crucial. In this article, we will delve into the best practices for installing and maintaining single cartridge seals. By following these guidelines, operators can improve equipment reliability, minimize downtime, and achieve optimal seal performance.

1. Pre-Installation Preparations

Before installing a single cartridge seal, thorough pre-installation preparations are necessary to ensure a successful and efficient process. This section covers some essential steps to follow:

a. Inspect the Seal:

Prior to installation, carefully inspect the seal for any visible damage or defects. Check for signs of wear, such as cracks, abrasions, or corrosion. If any issues are detected, it is important to rectify or replace the seal before proceeding with installation.

b. Review Equipment Documentation:

Familiarize yourself with the equipment documentation, including the manufacturer's instructions and recommended procedures for installing the single cartridge seal. Understanding these guidelines will help ensure correct installation and avoid potential issues.

c. Gather the Required Tools:

Assemble all the necessary tools and equipment needed for installation. This may include wrenches, pliers, Allen keys, torque wrenches, and any specific tools recommended by the seal manufacturer. Having the right tools readily available will streamline the installation process.

2. Seal Installation Process

Proper seal installation is crucial for its optimal performance. Following these steps will help ensure a reliable installation:

a. Clean the Equipment:

Thoroughly clean the equipment where the seal will be installed. Remove any dirt, debris, or leftover material as these contaminants can affect the seal's performance and lifespan. Ensure there are no rough or sharp edges that could cause damage during installation.

b. Apply Lubrication:

Apply a suitable lubricant to the seal components as per manufacturer recommendations. Lubrication helps reduce friction during installation and safeguards against unnecessary wear and tear.

c. Orient the Seal Correctly:

Pay close attention to the orientation of the single cartridge seal. Ensure it is aligned correctly with the equipment and that all seal faces and sealing elements are in the proper position. Improper orientation can lead to seal failure and leakage.

d. Tighten Bolts to Recommended Torque:

Use a calibrated torque wrench to tighten the bolts that secure the single cartridge seal. Follow the manufacturer's recommended torque values to avoid under or over-tightening, which can result in seal damage or leakage.

e. Conduct a Visual Inspection:

After installation, conduct a visual inspection to verify that the seal is correctly installed and aligned. Ensure that all components are properly seated and tightened, and that there are no visible signs of misalignment or damage.

3. Post-Installation Checks and Startup

Once the single cartridge seal is correctly installed, additional checks and startup procedures are necessary to ensure its proper operation. The following steps should be followed:

a. Conduct Leakage Test:

Before starting the equipment, perform a leakage test to verify that the seal is effectively sealing the rotating shaft. This can be done by introducing a controlled flow of liquid or gas and observing for any leakage or abnormal behavior.

b. Monitor Operating Parameters:

During the initial startup phase, closely monitor the operating parameters of the equipment, such as temperature, pressure, and speed. Ensure that these parameters remain within the recommended range and address any deviations promptly.

c. Check for Vibrations or Unusual Noises:

Pay attention to vibrations or unusual noises during the equipment startup. Excessive vibrations or unusual sounds can indicate misalignment, seal damage, or other mechanical issues. Address these concerns to prevent further damage or premature seal failure.

4. Routine Maintenance Practices

Regular maintenance is essential to prolonging the life and ensuring the continued performance of single cartridge seals. Implement the following routine maintenance practices:

a. Inspect and Clean the Seal:

Regularly inspect the single cartridge seal for signs of wear, damage, or debris accumulation. Clean the seal components as necessary, ensuring that no contaminants compromise the seal's integrity.

b. Monitor Seal Performance:

Continuously monitor the seal's performance by observing for any leaks, abnormal vibrations, or changes in equipment behavior. Regularly record and analyze operating parameters to identify any deviations or potential issues.

c. Replace Seals at Recommended Intervals:

Follow the manufacturer's recommended replacement intervals for single cartridge seals. Over time, seals may wear out, lose their effectiveness, or become damaged. Timely replacement helps prevent unexpected equipment failures and costlier repairs.

d. Train Personnel:

Ensure that personnel responsible for the installation and maintenance of single cartridge seals receive adequate training. Proper knowledge and understanding of best practices will minimize the risk of improper installation, inadequate maintenance, and subsequent seal failure.

Conclusion

Proper installation and maintenance of single cartridge seals are vital for ensuring their optimal performance and maximizing equipment reliability. By following the best practices outlined in this article, operators can enhance seal longevity, minimize downtime, and prevent costly repairs. Regularly inspecting, cleaning, and monitoring seal performance, combined with well-executed installation procedures, will contribute to a safer and more efficient industrial operation.