Innovations in Double Cartridge Mechanical Seal Design and Materials

Introduction:

Mechanical seals play a crucial role in ensuring the integrity and efficiency of rotating equipment in various industries. These seals are engineered to prevent leakage and contamination, maintaining the operational reliability of pumps, compressors, and other machinery. In recent years, advancements in double cartridge mechanical seal design and materials have revolutionized the industry, offering improved performance, durability, and ease of maintenance. This article explores the latest innovations in double cartridge mechanical seal design and the materials driving these advancements.

Enhanced Seal Performance with Dual Cartridge Designs

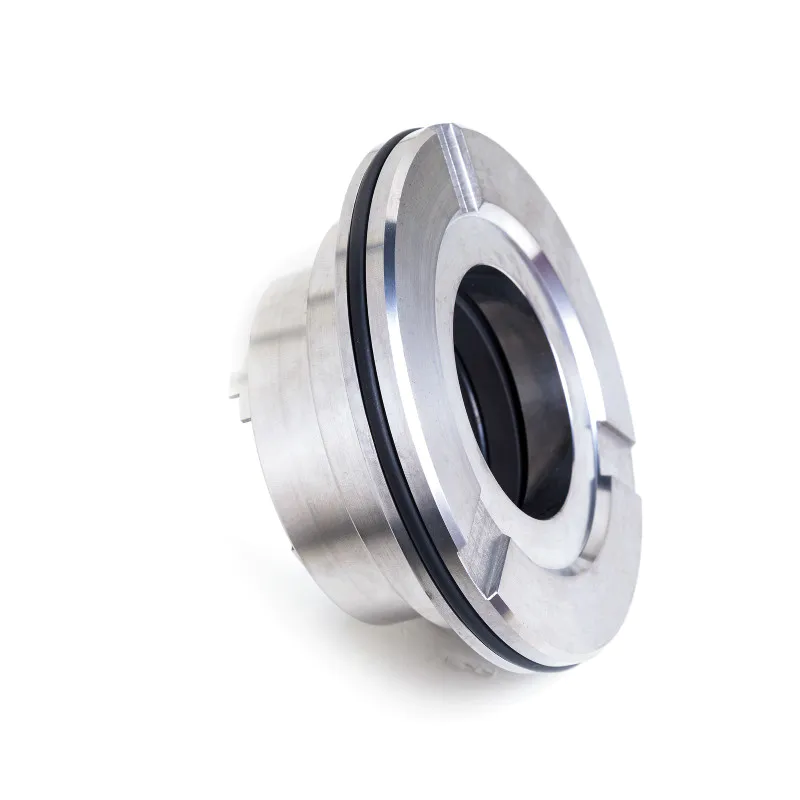

The double cartridge configuration is a significant breakthrough in mechanical seal technology. This design features two separate seals working in tandem to provide enhanced performance, combining the advantages of both single component and tandem seal designs. The primary seal, located closer to the process fluid, prevents leakage in the event of failure in the secondary seal. Meanwhile, the secondary seal acts as a backup, safeguarding against any potential fluid leakage. This dual cartridge approach significantly reduces the risk of process fluid contamination, enhancing safety and operational efficiency.

By incorporating dual mechanical seals, equipment manufacturers can ensure increased reliability and prolonged service life. The double cartridge configuration allows for easier monitoring and maintenance, as the seals can be inspected individually without requiring complete disassembly of the equipment. This feature reduces downtime and enhances overall operational efficiency. Moreover, the use of dual cartridge mechanical seals minimizes the risk of critical equipment failure, preventing costly repairs and facilitating uninterrupted production.

Advancements in Seal Design

The innovations in double cartridge mechanical seal design have further optimized seal performance, addressing common challenges faced in various industries. The industry's leading manufacturers have focused on developing features that enhance reliability, ease of installation, and performance.

One notable advancement is the inclusion of self-aligning technology in double cartridge seals. Traditionally, misalignment between rotary equipment and external pumps caused excessive leakage, leading to decreased efficiency and increased maintenance costs. With self-aligning double cartridge seals, the seals automatically adjust to accommodate misalignment, ensuring optimal performance and preventing premature seal failure. This feature reduces the need for constant realignment, saving time and resources for maintenance teams.

Additionally, some double cartridge seals now feature enhanced face geometry and advanced materials to improve sealing capabilities. The inclusion of laser-engraved microstructures on seal faces promotes better fluid film formation and reduces friction, resulting in lowered energy consumption and extended seal life. Furthermore, the use of advanced materials such as silicon carbide and ceramic helps resist corrosive and abrasive fluids, making double cartridge seals ideal for demanding applications.

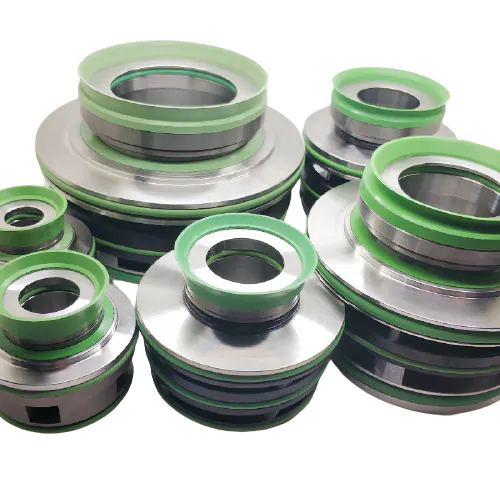

Materials Revolutionizing Double Cartridge Seals

The development of innovative materials has played a pivotal role in driving advancements in double cartridge mechanical seals. These materials offer superior chemical resistance, durability, and reliability, while also reducing friction and wear.

One such material that has gained popularity is advanced carbon graphite composites. These composites offer excellent chemical resistance and temperature tolerance, making them suitable for a wide range of applications. Furthermore, their self-lubricating properties minimize friction and wear, ensuring prolonged seal life. Advanced carbon graphite composite double cartridge seals have become the go-to solution for industries dealing with aggressive chemicals and extreme operating conditions.

Another material revolutionizing double cartridge mechanical seals is silicon carbide. Silicon carbide seals are known for their exceptional hardness, making them highly resistant to wear and abrasion. This material is particularly suitable for applications involving abrasive fluids, ensuring extended seal life and reduced maintenance requirements. Additionally, silicon carbide's superior chemical resistance and thermal conductivity make it a reliable choice for high-temperature applications, where conventional seals may fail.

Ease of Maintenance and Seal Replacement

Maintenance and replacement of mechanical seals are essential for ensuring optimal equipment performance and minimizing downtime. The innovations in double cartridge mechanical seal design have prioritized ease of maintenance, allowing for quick and hassle-free seal replacements.

Double cartridge seals are designed for easy installation and removal, making maintenance tasks more efficient. The modular design allows for individual seal replacement without dismantling the entire assembly, significantly reducing downtime and labor costs. Moreover, the use of standardized components ensures compatibility across different equipment models, simplifying the replacement process and eliminating the need for extensive reconfiguration.

Furthermore, some manufacturers have introduced innovative features like quick-connect cartridges, facilitating rapid seal replacement. These cartridges can be easily detached and reattached, speeding up maintenance procedures and reducing the risk of incorrect installation. These advancements contribute to shorter maintenance cycles, enabling businesses to maximize equipment uptime and minimize production disruptions.

Summary

Innovations in double cartridge mechanical seal design and materials have transformed the industry, providing improved performance, durability, and ease of maintenance. The dual cartridge configuration offers enhanced reliability, ensuring uninterrupted production and preventing costly downtime. The incorporation of self-aligning technology, advanced face geometry, and innovative materials has further optimized seal performance, addressing common industry challenges.

The development of advanced materials such as carbon graphite composites and silicon carbide has revolutionized double cartridge seal applications. These materials offer superior chemical resistance, reduced friction, and increased wear resistance, making them ideal for demanding environments. Moreover, the emphasis on ease of maintenance and seal replacement streamlines the upkeep process, reducing downtime and enhancing operational efficiency.

As the demand for reliability and efficiency in rotating equipment continues to grow, the innovations in double cartridge mechanical seal design and materials will play a crucial role in meeting these requirements. With ongoing research and development, the industry can expect even more breakthroughs that will further enhance the performance and longevity of double cartridge mechanical seals.