Flygt Mechanical Seals for Submersible Pump Applications: Waterproofing and Contamination Prevention

Article

1. Introduction: Understanding the Need for Flygt Mechanical Seals in Submersible Pump Applications

2. Waterproofing: How Flygt Mechanical Seals Protect Submersible Pumps from Water Damage

3. Contamination Prevention: Safeguarding Submersible Pumps against Harmful Particles

4. Key Features of Flygt Mechanical Seals: Durability and Performance Enhancement

5. Installation and Maintenance: Ensuring Optimal Functionality of Flygt Mechanical Seals in Submersible Pump Applications

Introduction: Understanding the Need for Flygt Mechanical Seals in Submersible Pump Applications

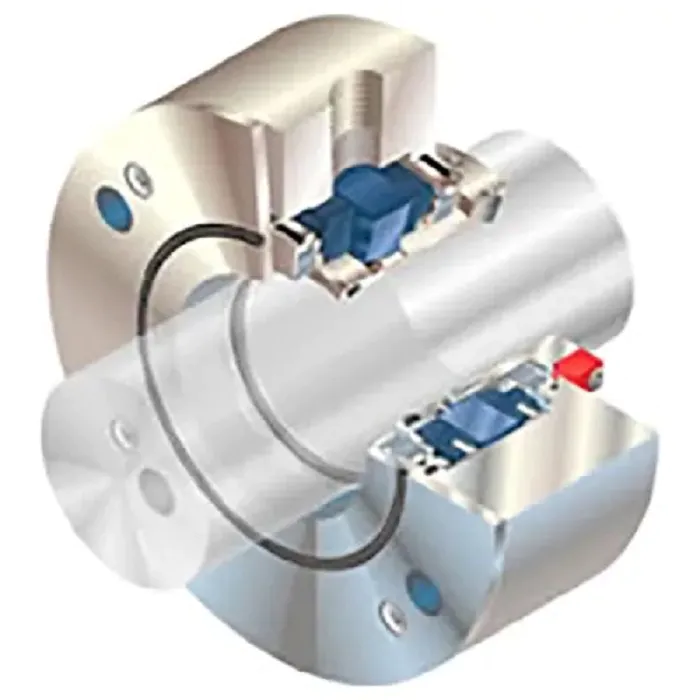

Submersible pumps play a crucial role in various industries, including wastewater management, mining, and oil and gas. These pumps are designed to operate underwater, making them indispensable in locations where water extraction or drainage is required. However, submersible pumps face the challenge of resisting water infiltration and preventing contamination from harmful particles. To address these issues, the implementation of reliable mechanical seals is necessary. Flygt, a renowned manufacturer of water and wastewater solutions, offers an advanced range of mechanical seals specifically designed for submersible pump applications. In this article, we will delve into the importance of waterproofing and contamination prevention in submersible pumps and explore the key features and benefits of Flygt mechanical seals.

Waterproofing: How Flygt Mechanical Seals Protect Submersible Pumps from Water Damage

Waterproofing is vital to the longevity and effectiveness of submersible pumps. The ingress of water into pump casings can lead to electrical short circuits, premature motor failure, and corrosion. Flygt mechanical seals effectively combat these challenges by creating a watertight barrier between the pump's internal and external environments. These seals are designed to withstand the high pressures and harsh conditions encountered in submersible applications.

Flygt mechanical seals utilize advanced sealing technologies, such as rubber bellows, to ensure a secure and reliable seal between the rotating shaft and pump housing. The rubber bellows provide flexibility and compensate for misalignment, thereby reducing the risk of seal failure due to shaft movements or vibrations. Additionally, Flygt mechanical seals incorporate secondary sealing elements, such as O-rings, to offer extra protection against water penetration.

Contamination Prevention: Safeguarding Submersible Pumps against Harmful Particles

In submersible pump applications, preventing contamination is crucial to avoiding equipment damage and operational disruptions. The presence of abrasive particles, chemicals, or debris can lead to seal degradation, reduced pump efficiency, and costly repairs. Flygt mechanical seals are designed to combat these challenges by incorporating features that effectively prevent contaminants from entering the pump's internal components.

One such feature is the utilization of hard-wearing materials in the construction of Flygt mechanical seals. The seals are made from high-quality stainless steel, which offers superior resistance to corrosion and wear caused by abrasive particles. Additionally, Flygt mechanical seals incorporate specially designed lip seal arrangements that act as an additional barrier against sediment and contamination.

Key Features of Flygt Mechanical Seals: Durability and Performance Enhancement

Flygt mechanical seals boast several key features that enhance their durability and overall performance. These features make them an ideal choice for submersible pump applications, where reliability and efficiency are paramount.

Firstly, Flygt mechanical seals feature a robust design, ensuring their ability to withstand the extreme conditions encountered in submersible pump operations. The materials used in the construction of these seals are carefully selected to resist corrosion, erosion, and wear, thereby extending their lifespan.

Secondly, Flygt mechanical seals are designed with simplicity in mind, enabling easy installation and maintenance. The seals can be quickly and efficiently replaced, allowing for minimal downtime during maintenance activities. This not only saves time but also reduces operational costs.

Installation and Maintenance: Ensuring Optimal Functionality of Flygt Mechanical Seals in Submersible Pump Applications

Proper installation and ongoing maintenance are crucial for maximizing the functionality and lifespan of Flygt mechanical seals in submersible pump applications. Following the manufacturer's guidelines and best practices ensures that the seals operate at their optimum capacity and minimize the risk of failure.

During installation, it is essential to verify the compatibility of the mechanical seal with the specific pump model. The seals should be fitted accurately, ensuring a proper alignment between the rotating shaft and pump housing. Any misalignment can lead to premature wear, leakage, and reduced performance.

Regular maintenance is equally vital in prolonging the lifespan of Flygt mechanical seals. Routine inspection enables early detection of any signs of wear, damage, or contamination. Regular cleaning and lubrication of the seals ensure their smooth operation and prevent the accumulation of debris or residues that could compromise their performance.

Conclusion

Flygt mechanical seals provide reliable waterproofing and contamination prevention for submersible pump applications. By effectively sealing the internal components of the pump, these seals contribute to enhanced performance, extended lifespan, and minimized downtime. The robust design, combined with the utilization of high-quality materials, ensures durability and resistance to harsh operating conditions. Proper installation and regular maintenance further optimize the functionality of Flygt mechanical seals. Therefore, for submersible pump applications requiring waterproofing and contamination prevention, Flygt mechanical seals are the ideal choice.