Flygt Mechanical Seals: Ensuring Leak-Free Operation in Submersible Pumps

Flygt Mechanical Seals: Ensuring Leak-Free Operation in Submersible Pumps

Introduction:

Submersible pumps play a vital role in various industries, ranging from wastewater treatment plants to mining operations. These pumps are designed to operate underwater, providing efficient and reliable pumping solutions. However, one of the key challenges faced by submersible pumps is preventing leakage. To overcome this challenge, Flygt, a leading manufacturer of submersible pumps, has developed innovative mechanical seals that ensure leak-free operation. In this article, we will explore the importance of mechanical seals in submersible pumps and discuss how Flygt's technology is revolutionizing the industry.

Understanding Mechanical Seals:

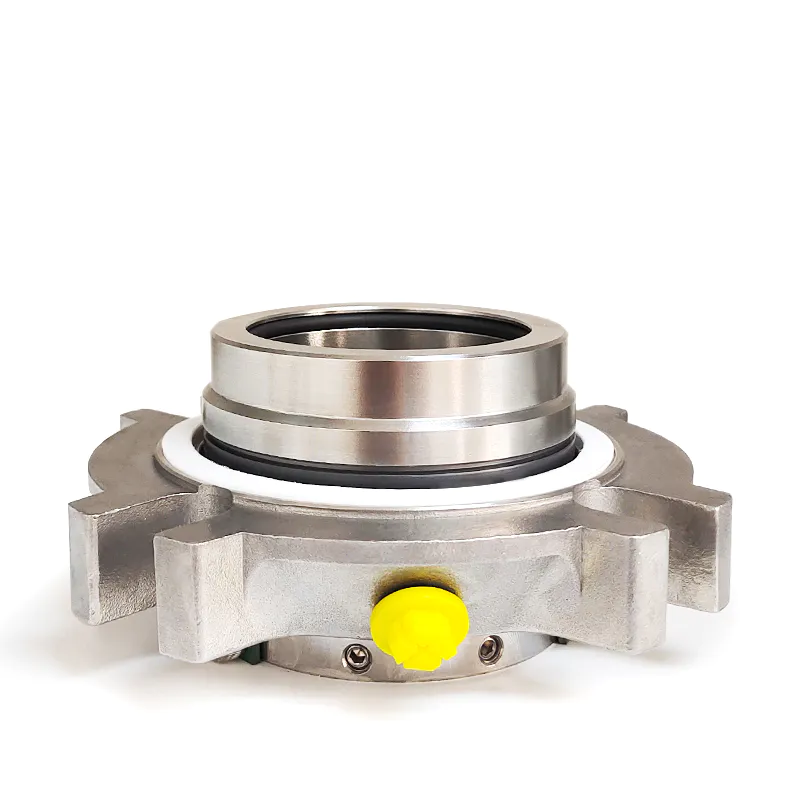

Mechanical seals are essential components in submersible pumps, responsible for sealing the gap between the rotating shaft and the pump casing. Their primary function is to prevent the pumped fluid from leaking out and water from seeping into the pump's motor. Mechanical seals consist of two main parts: a stationary component known as the 'seal seat' and a rotating component called the 'seal face.' When these two components are brought into contact, they create a barrier that prevents leakage.

1. The Significance of Leak-Free Operation:

Leakage is a major concern in submersible pumps as it can lead to various detrimental consequences. Firstly, any leakage in the pump system can result in a loss of efficiency, leading to increased energy consumption and higher operational costs. Secondly, if water infiltrates the pump's motor, it can cause severe damage, leading to costly repairs or even complete pump failure. Consequently, maintaining a leak-free operation is critical for ensuring the longevity and reliability of submersible pumps.

2. Flygt Mechanical Seals: Superior Design and Technology:

Flygt, a brand synonymous with quality and innovation, has developed advanced mechanical seals to address the challenges associated with submersible pump leakage. Their seals are designed using high-quality materials such as silicon carbide, which offers exceptional resistance to wear, corrosion, and thermal shock. Flygt seals are also engineered to withstand high pressure and capable of accommodating shaft movements, ensuring a secure and long-lasting seal.

3. Durable and Versatile Construction:

Flygt's mechanical seals are constructed with durability and versatility in mind. They are built to withstand the harsh operating conditions that submersible pumps are exposed to, including abrasive and corrosive fluids. Additionally, the seals are available in various sizes to accommodate different pump models and shaft diameters. This versatility ensures that Flygt seals can be seamlessly integrated into existing pump systems without extensive modifications.

4. Advanced Seal Monitoring Systems:

In addition to their robust construction, Flygt mechanical seals are equipped with advanced monitoring systems. These systems provide real-time feedback on the seal's performance, allowing operators to detect potential issues such as seal wear, misalignment, or inadequate lubrication. Timely detection of these issues enables proactive maintenance, minimizing the risk of unexpected pump failures and reducing downtime.

5. Cost-Effective Solution:

Flygt mechanical seals offer a cost-effective solution for submersible pumps. By ensuring leak-free operation and reducing the risk of motor damage, these seals contribute to prolonged pump lifespan and decreased maintenance costs. Additionally, their advanced monitoring systems help optimize maintenance schedules, preventing unnecessary downtime and maximizing operational efficiency. Investing in Flygt mechanical seals ultimately leads to significant long-term savings for pump operators.

Conclusion:

In conclusion, mechanical seals are vital components in submersible pumps, ensuring leak-free operation and protecting the pump's motor from water damage. Flygt's innovative mechanical seals have set new standards in the industry, providing superior reliability, durability, and versatility. With their advanced monitoring systems and cost-effective design, Flygt mechanical seals offer a comprehensive solution for pump operators, ensuring optimal performance and minimizing operational costs. By choosing Flygt mechanical seals, pump operators can have confidence in the longevity and dependability of their submersible pumps.