Flowserve Dry Gas Seals in Refinery Compressors: A Trusted Solution

Article

1. Introduction: Dry Gas Seals and their Importance in Refinery Compressors

2. Understanding the Need for a Trusted Solution

3. Flowserve Dry Gas Seals: Features and Benefits

4. Case Studies: Real-World Applications of Flowserve Dry Gas Seals

5. Conclusion: Why Flowserve Dry Gas Seals are the Ideal Solution for Refinery Compressors

Introduction: Dry Gas Seals and their Importance in Refinery Compressors

Refinery compressors play a crucial role in the oil and gas industry, enabling the transportation of various gases and fluids used in refining processes. These compressors are subject to extreme conditions, including high pressures, temperatures, and potentially corrosive environments. To ensure the reliable and efficient operation of refinery compressors, the selection of suitable sealing systems is of paramount importance. This article will delve into the trusted solution provided by Flowserve Dry Gas Seals, which have gained significant recognition in the industry.

Understanding the Need for a Trusted Solution

In refinery compressors, the seals serve the vital function of preventing leakage between the rotating shaft and the stationary housing. Traditional sealing methods often involved liquid-based systems, such as oil or water seals, which had several drawbacks. These included the potential for contamination, increased maintenance requirements, and limited reliability. As a result, the industry turned towards dry gas seals as a more effective and efficient alternative.

Dry gas seals are a specialized type of sealing mechanism that uses a controlled gas environment to prevent leakage. They offer numerous advantages over traditional liquid seals, including enhanced reliability and reduced environmental impact. The need for a trusted solution arises from the critical nature of refinery operations, where any unexpected downtime or leakage can lead to significant financial losses, environmental hazards, and safety concerns.

Flowserve Dry Gas Seals: Features and Benefits

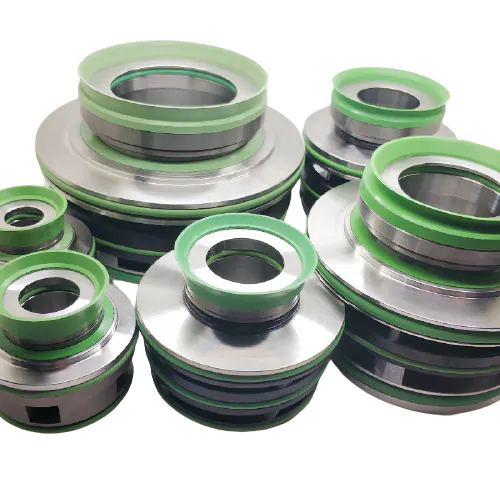

Flowserve, a leading manufacturer of industrial flow control products, has become renowned for its innovative and reliable sealing solutions. Flowserve's dry gas seals are specifically designed to meet the rigorous demands of refinery compressors. These seals offer a range of features and benefits that make them a trusted solution for operators worldwide.

1. Advanced Technology: Flowserve Dry Gas Seals incorporate cutting-edge technology, ensuring superior performance and reliability. By leveraging advanced materials and design principles, these seals deliver exceptional sealing efficiency, reducing the risk of leaks and minimizing the chance of equipment failure.

2. Enhanced Safety: With safety being a top priority in the oil and gas industry, Flowserve has incorporated multiple safety features into their dry gas seals. These include double seals with barrier gas systems, temperature and pressure monitoring, and emergency shutdown capabilities. Such safety measures provide peace of mind to operators, knowing that their compression systems are well-protected.

3. Robust Design: Flowserve's dry gas seals are engineered to withstand harsh environmental conditions encountered in refinery applications. They are designed to operate in high-temperature environments, resist corrosive substances, and maintain efficient sealing even under extreme pressures. This durability ensures a longer product life and minimizes maintenance requirements.

4. Flexibility and Adaptability: Refinery compressors often deal with varying gas compositions and operating conditions. Flowserve Dry Gas Seals are designed to handle a wide range of gas compositions, making them a versatile solution for different refining processes. Additionally, they can be customized and adapted to specific environmental requirements, offering a tailored solution to individual compressor systems.

Case Studies: Real-World Applications of Flowserve Dry Gas Seals

To understand the practical benefits of Flowserve Dry Gas Seals, let us explore some real-world case studies highlighting their successful implementation in refinery compressors.

1. Case Study 1: A leading oil refinery in the Middle East was experiencing recurrent leakage issues with their compressor seals, resulting in significant downtime and repair costs. By replacing the traditional liquid seals with Flowserve Dry Gas Seals, they witnessed a drastic reduction in leakage incidents and improved overall operational efficiency.

2. Case Study 2: A refinery in North America sought a reliable sealing solution for their high-pressure gas compression application. Flowserve Dry Gas Seals not only provided excellent leakage control but also demonstrated enhanced reliability, lowering maintenance requirements and decreasing equipment downtime.

Conclusion: Why Flowserve Dry Gas Seals are the Ideal Solution for Refinery Compressors

In conclusion, Flowserve Dry Gas Seals have emerged as a trusted solution for refinery compressors, offering numerous advantages over traditional liquid-based sealing systems. Their advanced technology, enhanced safety features, robust design, and flexibility make them a preferred choice for operators in the oil and gas industry. Through real-world case studies, it is evident that Flowserve Dry Gas Seals deliver reliable performance, improve operational efficiency, and minimize the risk of costly downtime. By opting for Flowserve Dry Gas Seals in refinery compressors, operators can ensure the continuity of their operations while maintaining a safer and more sustainable working environment.