Exploring Cutting-Edge Materials for Cartridge Seal Construction

Exploring Cutting-Edge Materials for Cartridge Seal Construction

Introduction:

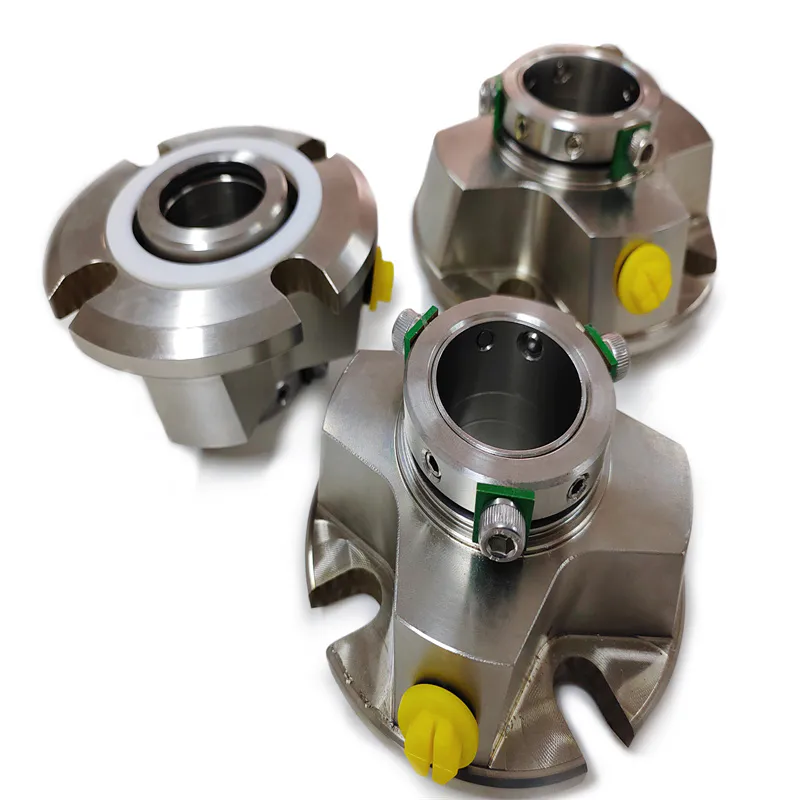

Cartridge seals play a crucial role in various industries, including oil and gas, chemical processing, and water treatment. These seals are responsible for preventing leakage and ensuring the efficient operation of pumps and rotating equipment. As technology continues to advance, the demand for more reliable and durable cartridge seals grows. This article delves into the realm of cutting-edge materials used in cartridge seal construction, highlighting their benefits and potential applications.

1. The Need for Advanced Materials:

In traditional cartridge seal construction, materials like carbon, silicon carbide, and ceramic have been widely used. While these materials have served industry needs effectively, the constant pursuit of enhanced performance and longevity necessitates the exploration of new cutting-edge materials. The demands of modern industrial processes, such as high temperatures, corrosive environments, and abrasive conditions, call for materials that can withstand these challenges and offer extended service life.

2. Graphene: The Revolutionary Material:

Graphene, a one-atom-thick layer of carbon atoms arranged in a hexagonal lattice, holds immense potential in cartridge seal construction. Its extraordinary properties, including exceptional strength, high thermal conductivity, and resistance to corrosion, make it an ideal candidate for sealing applications. Graphene-based cartridge seals exhibit enhanced performance, surpassing traditional materials by minimizing leakage, reducing friction, and increasing system efficiency. Moreover, graphene's versatility enables its application in various industries, offering innovative solutions across the board.

3. Ceramic Matrix Composites:

Ceramic matrix composites (CMCs) represent another exciting development in cartridge seal construction. These composites combine ceramic fibers with a matrix material, such as silicon carbide or alumina, resulting in a material with superior strength and toughness compared to conventional ceramics. CMCs offer exceptional wear resistance, high-temperature stability, and reduced brittleness, making them highly suitable for harsh operating conditions. Cartridge seals made from CMCs provide extended service life, reduce maintenance requirements, and enhance the overall reliability of equipment in demanding industries.

4. Polymeric Nanocomposites:

Polymeric nanocomposites, which combine polymers with nanoscale fillers, have emerged as a promising material for cartridge seal construction. These materials exhibit improved mechanical properties, such as increased tensile strength, wear resistance, and dimensional stability. Polymeric nanocomposites offer excellent chemical resistance and can withstand a wide array of operating temperatures. The incorporation of nanoparticles enhances the material's ability to withstand abrasive environments, ensuring a longer seal lifespan and reduced equipment downtime.

5. Elastomeric Blends:

Elastomers, commonly used in O-rings and seals, provide flexibility and seal integrity. However, their limitations, such as sensitivity to extreme temperatures and chemical exposure, have led to the development of elastomeric blends. These innovative materials combine the resilience of traditional elastomers with desirable characteristics, such as high-temperature resistance, chemical resistance, and improved mechanical properties. Cartridge seals utilizing elastomeric blends can withstand aggressive process fluids, extreme temperatures, and dynamic operating conditions, contributing to increased equipment reliability and longevity.

Conclusion:

As industries strive for improved efficiency, reduced downtime, and increased equipment reliability, the exploration of cutting-edge materials for cartridge seal construction becomes paramount. Graphene, ceramic matrix composites, polymeric nanocomposites, and elastomeric blends offer tremendous potential in addressing the challenges faced by modern industrial processes. These materials provide enhanced sealing performance, extended service life, and resistance to extreme operating conditions, making them invaluable assets across various sectors. The continued exploration and adoption of these revolutionary materials will undoubtedly shape the future of cartridge seal construction, pushing the boundaries of performance and reliability in industrial applications.