Enhancing Pump Reliability with High-Performance Flygt Pump Seals

Enhancing Pump Reliability with High-Performance Flygt Pump Seals

Introduction:

Pumps play a crucial role in various industries, from wastewater treatment plants to mining operations. However, pump failures can lead to costly downtime and maintenance issues. To address this problem, the industry has turned to high-performance Flygt pump seals. These seals offer enhanced reliability and durability, reducing the risk of pump failures and increasing overall efficiency.

Understanding the Importance of Pump Seals

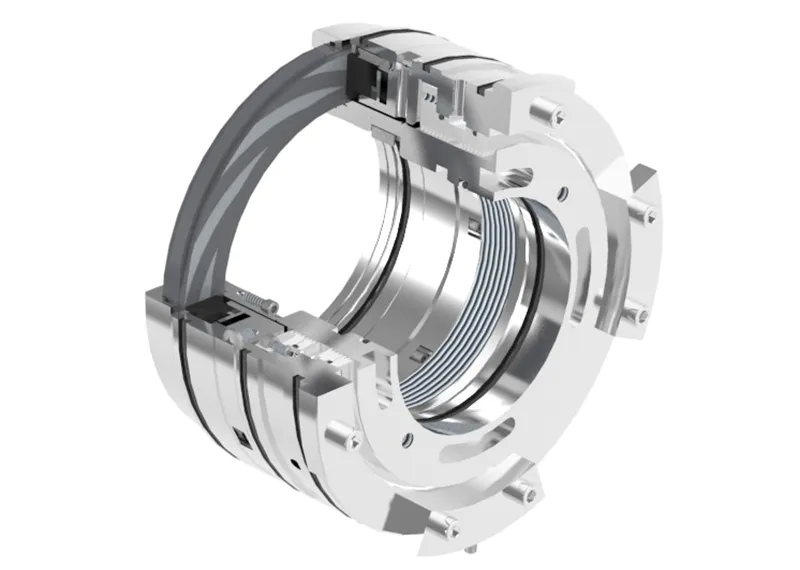

Pump seals are essential components that prevent leakage and maintain the integrity of the pumping system. They create a barrier between the rotating shaft and the stationary pump casing, ensuring that fluids or gases do not escape or enter unwanted areas. When pump seals fail, lubricants can escape, contaminants can enter, and the efficiency of the pump can be compromised. Therefore, investing in high-quality pump seals is crucial for optimizing pump performance.

The Advantages of Flygt Pump Seals

Flygt pump seals have gained widespread popularity due to their superior design and performance. These seals are specifically engineered to withstand harsh operating conditions and provide long-lasting reliability. Some key advantages of Flygt pump seals include:

1. Enhanced durability: Flygt pump seals are built to withstand extreme pressures, temperatures, and chemical exposure. They are constructed with high-quality materials such as advanced polymers and stainless steel, ensuring excellent resilience and resistance to wear.

2. Reduced leakage: Leakage is a common issue in pump systems, leading to energy wastage and environmental concerns. Flygt pump seals are designed to minimize leakage, maintaining system efficiency and preventing product loss.

3. Easy installation and maintenance: Flygt pump seals are designed for easy installation, reducing downtime during seal replacements. Additionally, their robust construction minimizes the need for frequent maintenance, saving both time and costs.

4. Versatility: Flygt pump seals are compatible with a wide range of pump types and sizes. Whether it's a centrifugal pump, submersible pump, or vertical turbine pump, Flygt offers seal solutions that fit different applications, making them suitable for diverse industries.

Key Industries Benefiting from Flygt Pump Seals

Flygt pump seals have revolutionized pump reliability and performance in various industries. Let's explore a few sectors that have witnessed substantial improvements after adopting high-performance Flygt pump seals:

1. Water and Wastewater Treatment: Treatment plants require reliable pumps to ensure efficient water and wastewater management. Flygt pump seals have proven to be highly effective in handling abrasive and corrosive fluids commonly found in these applications. By minimizing leaks and maintaining operational efficiency, Flygt pump seals contribute to reliable and cost-effective water treatment processes.

2. Chemical Processing: The chemical industry relies on pumps to transfer hazardous fluids. The use of Flygt pump seals ensures the integrity of the pumping system, preventing leaks that could result in dangerous situations or product contamination. The exceptional chemical resistance of Flygt pump seals makes them a preferred choice for chemical processing plants.

3. Mining and Construction: Mining operations involve harsh environments with high pressures and abrasive materials. Flygt pump seals can withstand these extreme conditions, ensuring efficient pumping and reducing the risk of downtime. By improving pump reliability, Flygt pump seals contribute to uninterrupted mining and construction activities.

4. Oil and Gas: The oil and gas industry demands reliable pumps to extract, transport, and refine petroleum products. Flygt pump seals offer superior performance in high-temperature, high-pressure environments, reducing the risk of leakage and maintaining operational efficiency. With their robust design, these seals enhance the safety and productivity of oil and gas operations.

Best Practices for Using Flygt Pump Seals

To maximize the benefits of Flygt pump seals, it is important to follow best practices during installation and maintenance. Here are some essential guidelines:

1. Select the right seal: Understand the specific requirements of your pump system and choose the appropriate Flygt pump seal. Consider factors such as operating temperature, pressure, and the properties of the fluid being pumped.

2. Proper installation: Ensure that the pump seal is installed correctly, following the manufacturer's instructions. Improper installation can lead to premature failure and reduced performance.

3. Regular inspections: Periodically inspect the pump seal for signs of wear, leaks, or damage. This proactive approach allows for timely maintenance and replacement, avoiding unexpected failures.

4. Lubrication and flushing: Provide adequate lubrication to the pump seal and flush the system regularly to remove any debris or contaminants that may affect its performance.

Conclusion

High-performance Flygt pump seals have proven to be game-changers in the pumping industry. By enhancing reliability, reducing leakage, and providing long-lasting durability, these seals optimize pump performance in various applications. Whether it's water and wastewater treatment, chemical processing, mining, or oil and gas, Flygt pump seals offer a cost-effective solution to improve pump reliability and efficiency. To ensure the best results, it is essential to select the right seal, follow proper installation procedures, conduct regular inspections, and provide adequate lubrication. With Flygt pump seals, pump failures can be minimized, leading to increased productivity and reduced maintenance costs.