Double Cartridge Mechanical Seals: Best Practices for Installation and Maintenance

Introduction to Double Cartridge Mechanical Seals

In the world of industrial pumps, ensuring a reliable seal is crucial for maintaining efficient operation and preventing leakage. This is where double cartridge mechanical seals come into play, providing a robust solution to seal integrity. These innovative seals offer enhanced performance and reliability, making them an ideal choice for various applications across industries such as chemical, pharmaceutical, oil and gas, and more.

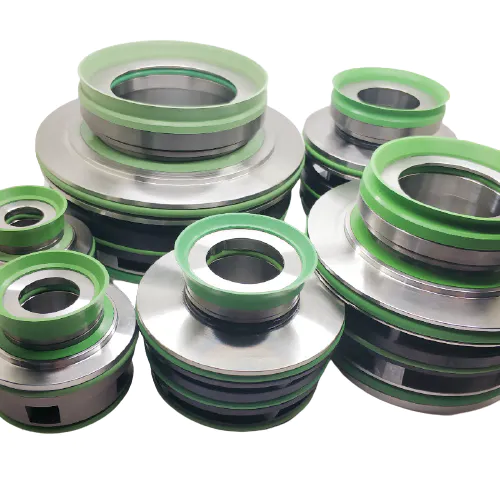

Double cartridge mechanical seals consist of two sets of sealing faces, known as the primary and secondary seals, that are housed in separate cartridges. This design offers numerous advantages over traditional single seals, including improved sealing capability, reduced downtime, and increased durability. However, to maximize the performance and lifespan of these seals, proper installation and maintenance practices are essential. In this article, we will delve into the best practices for the installation and maintenance of double cartridge mechanical seals, ensuring optimal performance and longevity.

Understanding Double Cartridge Mechanical Seals

Overview of Double Cartridge Mechanical Seals

Double cartridge mechanical seals are designed to withstand arduous conditions and maintain a leak-free environment. The primary and secondary seals work in tandem to prevent any process fluid from escaping the pump, ensuring the integrity of the system. These seals are commonly used in applications where leakage cannot be tolerated or poses safety risks.

The primary seal, positioned closest to the fluid being pumped, is responsible for the initial containment of the process fluid. Should any leakage occur, the secondary seal acts as a backup, providing an extra layer of protection. In the event of a primary seal failure, the secondary seal acts as a safety measure, preventing the fluid from entering the environment and avoiding potential hazards.

Advantages of Double Cartridge Mechanical Seals

Double cartridge mechanical seals offer several advantages over traditional single seals, making them a preferred choice for critical applications. Let's explore some of these key benefits:

1. Enhanced Sealing Capability: The primary and secondary seals working in tandem improve the overall sealing capability of the system, reducing the risk of leakage. This ensures the integrity of the process and minimizes the chances of costly downtime.

2. Increased Reliability: The redundancy provided by double cartridge mechanical seals enhances system reliability. In the event of a primary seal failure, the secondary seal takes over, mitigating the risk of process fluid escaping into the surroundings.

3. Easy Installation: Double cartridge mechanical seals are designed for ease of installation. The cartridge-style construction simplifies the installation process, reducing the time and effort required for maintenance personnel.

4. Reduced Downtime: The redundant design of double cartridge mechanical seals minimizes downtime. If a seal fails, maintenance personnel can replace the damaged cartridge without disassembling the entire pump, resulting in significant time savings.

5. Longer Lifespan: With proper installation and maintenance, double cartridge mechanical seals can have an extended lifespan compared to single seals. This extends the time between replacements, reducing overall costs and enhancing operational efficiency.

Installation Best Practices for Double Cartridge Mechanical Seals

Proper installation is crucial to ensure the effectiveness and reliability of double cartridge mechanical seals. Here are some best practices to follow during the installation process:

1. Pre-Installation Inspection: Before installing a double cartridge mechanical seal, conduct a thorough inspection of the pump and its components. Check for any signs of damage or wear that may impact the seal's performance. Replace any worn-out or damaged parts to ensure optimal functioning.

2. Proper Alignment: Ensure proper alignment of the pump and its components to avoid excessive vibration and premature seal failure. Misalignment can cause uneven wear on the sealing faces, leading to leaks. Follow the manufacturer's guidelines for alignment procedures and use appropriate tools if necessary.

3. Correct Torque Application: Apply the recommended torque when tightening the gland plate to prevent excessive pressure on the seal faces. Applying too much torque can damage the seal, while insufficient torque may not provide adequate compression, resulting in leaks. Always refer to the manufacturer's instructions for the recommended torque values.

4. Lubrication and Flushing: Prior to installation, ensure the sealing faces and o-rings are clean and free from any debris. Apply a thin film of compatible lubricant to the sealing faces to reduce friction and aid in the initial break-in period. Additionally, flush the system thoroughly to remove any contaminants that could affect the seal's performance.

5. Proper Cooling and Ventilation: Ensure the double cartridge mechanical seal is adequately cooled and ventilated. Excessive heat can degrade the seal material, leading to premature failure. Monitor the system's temperature and, if necessary, implement cooling measures such as cooling jackets or external cooling systems.

Maintenance Considerations for Double Cartridge Mechanical Seals

Maintaining double cartridge mechanical seals is crucial to ensure their continued performance and longevity. Here are some maintenance practices to follow:

1. Regular Inspections: Conduct routine inspections to check for signs of wear, leaks, or other issues. Inspect the sealing faces, o-rings, and other critical components for any damage. Promptly replace any worn-out or damaged parts to prevent potential failures.

2. Proper Cleaning: Regularly clean the sealing faces and o-rings to remove any dirt, residue, or process fluid build-up. Use compatible cleaning agents and follow the manufacturer's instructions to avoid damaging the seals. Clean surroundings and process conditions contribute to an extended seal lifespan.

3. Monitoring and Adjusting Seal Parameters: Monitor the seal's operating parameters such as temperature, pressure, and vibration regularly. Deviations from normal operating conditions may indicate a problem. Make necessary adjustments or consult with maintenance personnel to address any issues promptly.

4. Lubrication and Barrier Fluid Management: Check the lubrication and barrier fluid levels regularly, and replace them as recommended by the manufacturer. Ensure that the barrier fluid is compatible with the process fluid and operating conditions. Contaminated or insufficient barrier fluid can compromise seal performance.

5. Training and Documentation: Train maintenance personnel on proper installation and maintenance procedures for double cartridge mechanical seals. Maintain detailed documentation of seal-specific information, including installation dates, replacement history, and any relevant maintenance records. This information aids in troubleshooting and identifying potential areas for improvement.

Conclusion

Double cartridge mechanical seals offer robust sealing solutions for industrial pumps, ensuring process integrity and preventing leakage. Proper installation and maintenance practices are essential to maximize their performance and lifespan. By following the best practices outlined in this article, including pre-installation inspections, correct alignment, appropriate torque application, regular maintenance, and inspections, you can enhance the reliability and longevity of double cartridge mechanical seals. With their enhanced sealing capability, easy installation, and extended lifespan, these seals prove to be a valuable asset for various industries, contributing to efficient and reliable operations. So, make sure to implement these best practices to experience the full benefits of double cartridge mechanical seals in your pumping systems.