Critical Applications: Blackmer Pump Seals in Chemical and Process Industries

In the highly demanding and challenging chemical and process industries, every aspect of equipment and machinery must be carefully designed and meticulously engineered to ensure safe and efficient operations. One such crucial component is the pump seal, which plays a vital role in preventing leakages and ensuring the integrity of the entire system. Blackmer, a renowned manufacturer of positive displacement pumps, has established itself as a trusted supplier of high-quality pump seals that excel in critical applications within these industries.

Enhancing Safety and Reliability with Cutting-Edge Design

Blackmer understands the criticality of pump seals in chemical and process industries, where failure can lead to hazardous leaks, costly downtime, and environmental contamination. Therefore, they have invested heavily in research and development to create advanced pump seals that outperform traditional designs. These innovative seals are crafted using state-of-the-art materials and technologies to provide exceptional performance, durability, and safety.

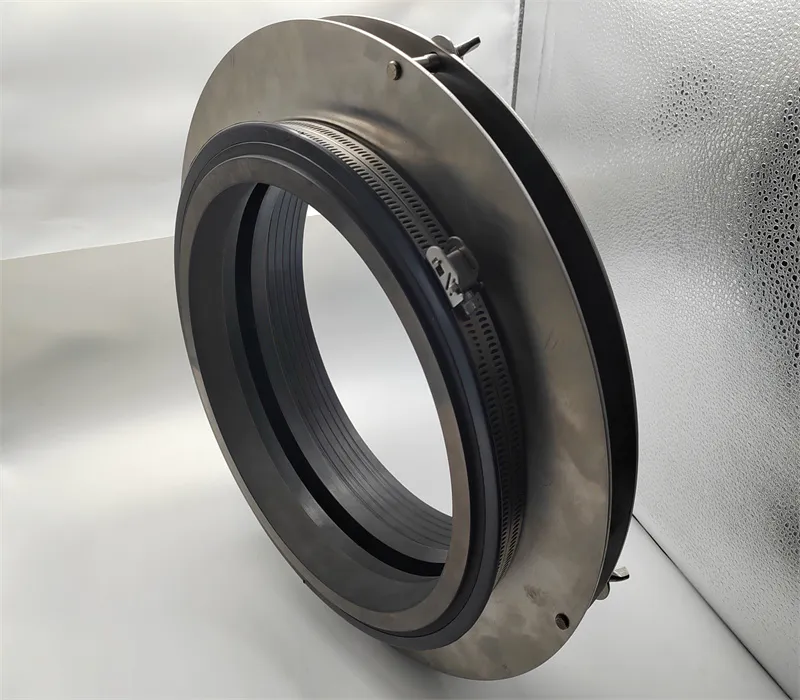

One of the key features of Blackmer pump seals is their robust construction. They are designed to withstand the harshest operating conditions, including high pressures, extreme temperatures, and aggressive chemicals. This ensures reliable and long-lasting performance, even in the most demanding applications.

Sealing Solutions for a Wide Range of Chemicals

Chemical and process industries involve handling various types of corrosive, abrasive, and toxic chemicals. Blackmer pump seals are specifically engineered to handle a wide range of chemical substances, making them highly versatile and suitable for diverse applications.

The seals are designed to resist chemical attack, preventing leakage and contamination of the process fluid. They are compatible with a broad spectrum of substances, including acids, alkalis, solvents, and other aggressive chemicals. This versatility allows operators to use Blackmer pump seals across multiple processes, ensuring efficient operations and reduced inventory requirements.

Reducing Downtime and Maintenance Costs

Minimizing downtime and maintenance costs is a top priority in the chemical and process industries. Blackmer pump seals offer several features that contribute to achieving these objectives.

Firstly, the seals are designed for easy installation and maintenance. With user-friendly designs and standardized components, they can be quickly and efficiently replaced, reducing downtime and optimizing productivity. The simplicity of their construction allows for hassle-free maintenance, minimizing the need for specialized tools or extensive training.

Additionally, the durability of Blackmer pump seals translates into extended operational life, resulting in fewer replacements and reduced maintenance costs. The advanced materials used in their construction exhibit exceptional wear resistance, further enhancing their reliability and longevity. Operators can rely on Blackmer pump seals to withstand the rigors of continuous operation, reducing the frequency of downtime-inducing failures.

Elevating Environmental Stewardship with Zero Leakage

Environmental considerations are paramount in today's chemical and process industries. Leakage of hazardous substances not only poses a threat to the environment but also leads to regulatory compliance issues and potential legal consequences. Blackmer pump seals are designed to address these concerns with their zero-leakage design.

The precise engineering and high-performance materials used in Blackmer pump seals ensure an absolute seal with no leakage. This guarantees that harmful chemicals do not escape into the environment, safeguarding the surroundings from contamination. The impeccable sealing properties of these seals improve overall system safety and support operators in achieving their environmental stewardship goals.

Proven Reliability and Global Support

Blackmer's reputation for delivering top-quality products that excel in critical applications is well-established in the chemical and process industries. Their pump seals have undergone rigorous testing and have been proven to meet the stringent requirements of these demanding sectors.

Furthermore, Blackmer provides comprehensive global support to its customers. Their technical experts are available to assist with seal selection, installation, and troubleshooting. This level of support ensures that operators can maximize the performance and reliability of their pump seals, minimizing the risks associated with critical applications.

In conclusion, Blackmer pump seals have emerged as a preferred choice for critical applications in the chemical and process industries. Their cutting-edge design, versatility, durability, and environmental compliance make them an ideal sealing solution for a wide range of aggressive chemicals and demanding operating conditions. With Blackmer pump seals, operators can enhance safety, reduce downtime and maintenance costs, and achieve environmental stewardship goals. The combination of proven reliability and global support positions Blackmer as a trusted partner for the unique challenges faced by these industries.