Choosing the Right Grundfos Pump Mechanical Seals for Specific Operating Conditions

Introduction:

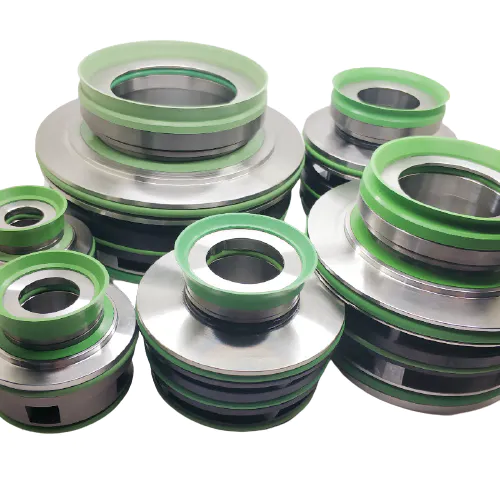

When it comes to operating machinery, it is crucial to ensure all components are functioning optimally. One particularly vital component in pump systems is the mechanical seal. A mechanical seal serves as a crucial barrier between the pump's rotating shaft and the stationary pump housing, preventing leakage and maintaining efficiency. In this article, we will explore the various factors to consider when selecting the right Grundfos pump mechanical seals for specific operating conditions. By understanding these considerations, you can make informed decisions that result in reliable and long-lasting pump performance.

The Importance of Selecting the Right Mechanical Seal

Selecting the appropriate mechanical seal for your Grundfos pump is paramount to avoid premature failure, minimize downtime, and extend the lifespan of your equipment. Each application has its unique operating conditions, including pressure, temperature, and the type of fluid being pumped, which can greatly influence the seal's performance. Therefore, it is crucial to understand these factors and choose a mechanical seal that can withstand the specific demands of your application.

Pressure Considerations:

Operating under incorrect pressure conditions can lead to catastrophic failures, such as seal blowout or leakage. When selecting a mechanical seal, it is crucial to consider the maximum and minimum pressure limits that your system may encounter. Grundfos pump mechanical seals are designed to operate reliably within specific pressure ranges, ensuring proper functioning and preventing premature failure. Consulting the manufacturer's specifications and recommendations can help you identify the ideal mechanical seal for your operating conditions.

Temperature Considerations:

Temperature is another crucial factor to consider when choosing a mechanical seal. Extreme temperature variations can compromise the seal's integrity, leading to failures that may disrupt operations and result in costly repairs. Grundfos provides seals suitable for different temperature ranges, enabling you to select one that aligns with your application's requirements. Matching the seal's material composition and design to the temperature conditions is essential for reliable and consistent pump performance.

Fluid Compatibility:

The type of fluid being pumped plays a significant role in the selection of the mechanical seal. Different fluids have varying properties that can affect the seal's performance. Some fluids may be corrosive, abrasive, or contain solids that can cause wear and tear. Grundfos offers a wide range of mechanical seals with different face materials, such as carbon, ceramic, or tungsten carbide, to ensure compatibility with various fluids. Understanding the characteristics of the pumped fluid and its potential impact on the seal can help you make an informed choice.

Shaft Speed:

The speed at which the pump operates is critical in determining the appropriate mechanical seal design. High-speed applications require seals capable of withstanding the increased rotational forces and heating generated. Grundfos pump mechanical seals are designed to accommodate different shaft speeds, ensuring they can handle the specific demands of your system. Failing to match the seal's design to the shaft speed can result in excessive wear, overheating, and premature failure.

Quality and Reliability:

Lastly, but certainly not least, when choosing a mechanical seal for your Grundfos pump, it is essential to consider the quality and reliability offered by the manufacturer. Grundfos is renowned for its commitment to delivering high-performance pumping solutions. Their mechanical seals are meticulously engineered and undergo rigorous testing to guarantee optimal performance and durability in demanding operating conditions. By choosing a reputable manufacturer known for their quality standards, you can have confidence in the reliability of the mechanical seals you select.

Summary:

In summary, choosing the right Grundfos pump mechanical seals for specific operating conditions requires careful consideration of several factors. Ensuring the mechanical seal can handle the pressure, temperature, and fluid compatibility is crucial for optimal pump performance. Additionally, selecting a seal designed for the required shaft speed, as well as prioritizing quality and reliability, is essential. By paying attention to these considerations and consulting the manufacturer's specifications, you can confidently select mechanical seals that deliver longevity, efficiency, and minimize downtime for your Grundfos pump system. Remember, investing in the right mechanical seals from the start can save you time, money, and headaches down the line.