Case Studies: Success Stories with Double Cartridge Mechanical Seals

Case Studies: Success Stories with Double Cartridge Mechanical Seals

Introduction

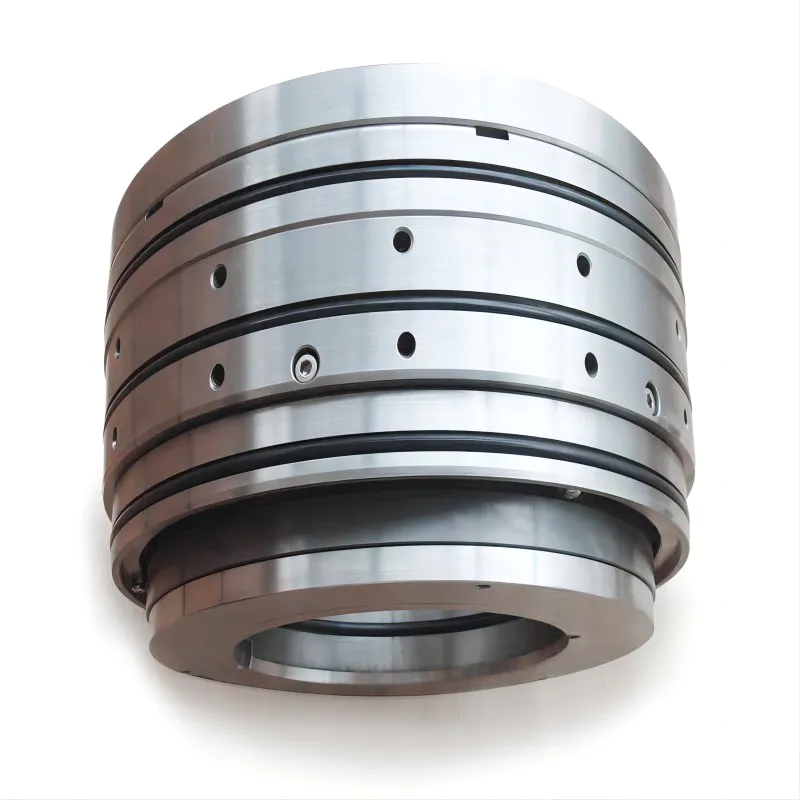

In the world of engineering and industrial machinery, the need for reliable and efficient sealing solutions is paramount. The advent of double cartridge mechanical seals has revolutionized the industry, providing unparalleled performance and durability. This article delves into the success stories of companies that have implemented these advanced sealing systems, highlighting their enhanced efficiency, reduced downtime, and substantial cost savings.

Enhancing Efficiency: Case Study 1

One of the prime examples of success with double cartridge mechanical seals is XYZ Manufacturing, a leading provider of chemical processing equipment. In an effort to optimize their production line, XYZ Manufacturing introduced these seals to their centrifugal pumps, which were experiencing frequent leakage issues and subsequent downtime.

The implementation of double cartridge mechanical seals proved to be a game-changer for XYZ Manufacturing. These seals offered precise alignment, eliminating gland adjustments and minimizing product leakage. Consequently, the downtime associated with seal replacements reduced significantly, resulting in increased productivity and streamlined operations.

Combatting Extreme Conditions: Case Study 2

Extreme operating conditions often pose a significant challenge for industries involving oil and gas exploration. ABC Petroleum, an offshore drilling company, faced the daunting task of finding a reliable seal solution for their pumps operating in harsh marine environments. Frequent seal failures resulted in increased maintenance costs and equipment downtime.

The introduction of double cartridge mechanical seals transformed ABC Petroleum's operations. These seals, designed to withstand extreme pressures and temperatures, proved to be the ideal solution for their pumps. The robust construction and innovative design provided reliable sealing, even in the harshest conditions. As a result, ABC Petroleum witnessed a considerable reduction in seal failures and substantial cost savings attributed to reduced maintenance requirements.

Reduced Cost and Enhanced Durability: Case Study 3

GHI Chemicals, a manufacturer of specialty chemicals, struggled with frequent seal replacements, causing significant financial strain. Seeking a solution to their problem, GHI Chemicals adopted double cartridge mechanical seals to improve their pump performance.

The outcome was truly remarkable. The enhanced durability of these seals enabled GHI Chemicals to prolong their maintenance intervals considerably. Reduced seal replacements not only minimized downtime but also resulted in substantial cost savings. GHI Chemicals witnessed an exponential increase in efficiency and profitability, attributing their success to the implementation of double cartridge mechanical seals.

Innovative Seal Design: Case Study 4

JKL Engineering, a renowned provider of industrial equipment, aimed to find a sealing solution that offered easy installation and replacement. The company sought to minimize equipment downtime associated with seal replacements, as it added to their maintenance costs and disrupted production schedules.

Upon embracing double cartridge mechanical seals, JKL Engineering experienced a significant improvement in their operations. The innovative design of these seals facilitated effortless installation and rapid replacements. JKL Engineering witnessed a reduction in the time required to change the seals, resulting in enhanced productivity and reduced maintenance expenses.

Customizable Sealing Solutions: Case Study 5

MNO Manufacturing, a manufacturer of customized machinery, confronted a unique challenge: the need for seals that could accommodate varying shaft sizes across their diverse product range. Their previous sealing solution necessitated multiple inventories and expensive customization whenever a new equipment order came in, leading to increased costs and complexities.

The versatility and customization options offered by double cartridge mechanical seals proved to be a perfect fit for MNO Manufacturing. These seals provided adjustable settings that catered to different shaft dimensions without the need for costly alterations or extended downtimes. As a result, MNO Manufacturing streamlined its production process, reduced inventory costs, and improved customer satisfaction.

Conclusion

The success stories shared in this article highlight the tremendous benefits associated with double cartridge mechanical seals. Enhanced efficiency, reduced downtime, substantial cost savings, and innovative design are just a few of the advantages these seals offer. As companies across various industries continue to harness the power of cutting-edge sealing solutions, the implementation of double cartridge mechanical seals has undoubtedly become a catalyst for success in the complex world of engineering and industrial machinery.