Cartridge Type Mechanical Seals in Pharmaceutical Manufacturing: Ensuring Product Purity

Cartridge Type Mechanical Seals in Pharmaceutical Manufacturing: Ensuring Product Purity

Introduction:

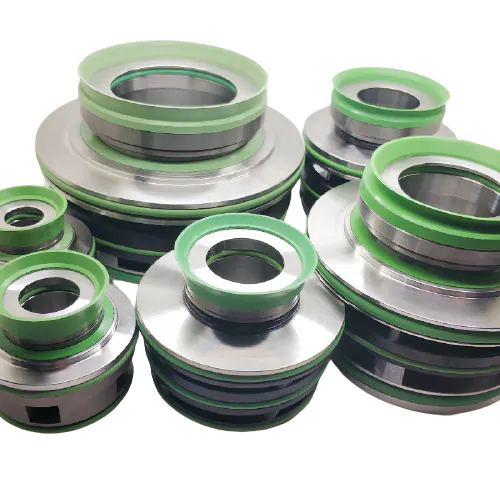

In the pharmaceutical manufacturing industry, product purity is of utmost importance. To ensure the highest level of quality and safety, mechanical seals play a vital role. Among the various types of mechanical seals available, cartridge type mechanical seals have gained significant popularity due to their efficiency and ability to maintain product integrity. This article explores the significance of cartridge type mechanical seals in pharmaceutical manufacturing, highlighting their benefits and impact on product purity.

Understanding Mechanical Seals:

Before delving into cartridge type mechanical seals, it is essential to understand the purpose and functioning of mechanical seals in pharmaceutical manufacturing. Mechanical seals are devices used to prevent the leakage of fluids (liquid or gas) in machinery. They create a barrier between the rotating and stationary components, ensuring a leak-free system.

1. The Importance of Product Purity in Pharmaceutical Manufacturing:

Product purity is critical in pharmaceutical manufacturing as it directly impacts the safety and effectiveness of medications for consumers. Any contamination, even at minute levels, can have detrimental effects on patient health. Cartridge type mechanical seals address this concern by providing a robust and reliable sealing solution.

2. Advantages of Cartridge Type Mechanical Seals:

2.1 Increased Reliability:

Cartridge type mechanical seals offer enhanced reliability by eliminating the need for separate seal components. Unlike traditional seals, cartridge seals include all necessary elements within a single unit, making maintenance and installation simpler and more streamlined.

2.2 Easy Installation and Replacement:

The design of cartridge seals allows for quick and straightforward installation. These seals are pre-assembled in a controlled environment, ensuring proper alignment and reducing the chances of errors during installation. Additionally, replacing a cartridge seal is efficient as it involves swapping the entire unit instead of individual components.

2.3 Reduced Downtime and Increased Productivity:

Cartridge type mechanical seals minimize downtime by reducing the time required for seal maintenance. In a pharmaceutical manufacturing setup, where time is of the essence, this leads to improved productivity and operational efficiency.

2.4 Enhanced Leakage Prevention:

Product purity is directly related to the ability of mechanical seals to prevent leakage effectively. Cartridge type seals are specifically designed to handle the rigorous demands of pharmaceutical manufacturing, ensuring a high level of sealing integrity that prohibits any contamination from entering the system.

3. Factors to Consider when Choosing Cartridge Type Seals:

3.1 Compatibility:

When selecting cartridge type mechanical seals, it is crucial to ensure compatibility with the specific pharmaceutical process and substances involved. Seals need to resist corrosion and withstand the chemicals used in manufacturing without compromising product purity.

3.2 Material Selection:

The choice of sealing material is vital to maintain the integrity of pharmaceutical products. Materials that conform to regulatory standards and possess high chemical resistance, like FDA-approved elastomers, are preferred for cartridge type mechanical seals.

3.3 Seal Design and Configuration:

The design and configuration of cartridge seals should be assessed based on the specific requirements of the pharmaceutical manufacturing process. Factors such as pressure, temperature, and sealing gap need to be considered to select the most suitable seal design.

4. Maintenance and Regular Inspection:

To ensure the longevity and efficacy of cartridge type mechanical seals, regular maintenance and inspections are essential. This includes monitoring seal performance, verifying proper installation, and addressing any signs of wear or damage promptly. Adhering to a preventive maintenance schedule will not only extend the lifespan of the seals but also contribute to maintaining product purity.

5. Industry Standards and Regulatory Compliance:

The pharmaceutical manufacturing industry is heavily regulated to ensure the safety and quality of medications. When integrating cartridge type mechanical seals into manufacturing processes, adherence to industry standards and regulatory compliance is crucial. Seals should comply with regulations such as cGMP (current Good Manufacturing Practices) to ensure the highest levels of product purity and patient safety.

Conclusion:

In the pharmaceutical manufacturing industry, product purity is paramount. Cartridge type mechanical seals offer a reliable and efficient solution to maintain product integrity and prevent contamination. With their numerous advantages, including increased reliability, easy installation, reduced downtime, and enhanced leakage prevention, cartridge seals are becoming an integral component of pharmaceutical manufacturing processes. By considering compatibility, material selection, seal design, and adherence to industry standards, manufacturers can ensure the effective implementation of cartridge type mechanical seals, ultimately contributing to the production of safe and pure pharmaceutical products.