Cartridge Seals: Addressing Environmental Compliance and Emissions Control

Cartridge Seals: Addressing Environmental Compliance and Emissions Control

Introduction to Cartridge Seals and their Importance in Industrial Applications

In today's era of increased environmental awareness and sustainability, industries are constantly seeking innovative solutions to reduce emissions and comply with rigorous environmental regulations. One such solution is cartridge seals, which play a pivotal role in addressing both environmental compliance and emissions control. This article delves into the significance of cartridge seals in various industrial applications and highlights their positive impact on the environment.

Understanding Cartridge Seals and Their Mechanism

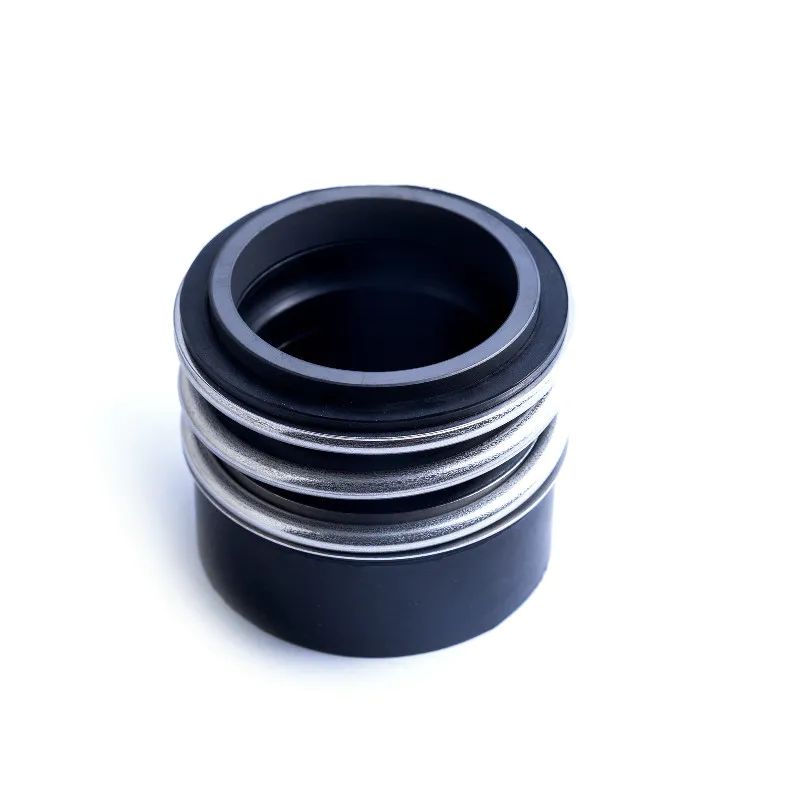

Cartridge seals are sealing devices used in rotating equipment, such as pumps, compressors, and mixers, to prevent leakage and maintain the integrity of the system. Unlike traditional component seals, cartridge seals are pre-assembled units that are easier to install, require minimal adjustment, and reduce the risk of installation errors. Their compact design and standardized dimensions allow for universal interchangeability and make them a popular choice in various industries.

Cartridge seals operate using a simple yet effective mechanism. They consist of two primary components - a rotating seal face attached to the shaft and a stationary seal face mounted in a housing. The two seal faces are pressed together using a spring, creating a frictional force that prevents any fluid leakage. Depending on the application, different face materials, such as carbon, silicon carbide, or tungsten carbide, are chosen to suit the specific operating conditions and ensure excellent sealing performance.

Benefits of Cartridge Seals for Environmental Compliance

Cartridge seals offer several key advantages that significantly contribute to environmental compliance efforts. Firstly, their superior sealing capabilities minimize fluid leakage, reducing the release of harmful substances into the surrounding environment. By preventing leaks, cartridge seals help industries meet stringent regulations regarding emissions control, avoiding hefty fines and potential damage to their reputation.

Furthermore, the pre-assembled nature of cartridge seals eliminates the need for on-site seal assembly, minimizing the risk of errors that could lead to leaks and subsequent environmental damage. Their standardized design simplifies installation, reduces downtime, and improves operational efficiency. Cartridge seals also require less maintenance compared to traditional component seals, further reducing the risk of system failures and potential environmental hazards.

Cartridge Seals as a Step Towards Sustainability

Beyond their role in environmental compliance, cartridge seals contribute to broader sustainability goals. By reducing emissions and preventing fluid leaks, these seals help conserve valuable resources. The prevention of leaks also minimizes product loss, increasing efficiency and reducing waste.

Cartridge seals are designed for longevity and durability, with advanced features such as self-cleaning capabilities, low-friction materials, and optimized design configurations. These characteristics enhance the lifespan of the seals, reducing the need for frequent replacements and minimizing overall waste generation. Their standardized dimensions and interchangeability also ensure compatibility with existing equipment, eliminating the need for extensive modifications or replacements.

Cartridge Seals: Applications and Industry Examples

Cartridge seals find extensive applications across a wide range of industries. One prominent sector that benefits from cartridge seals is the oil and gas industry. In oil refineries, where leakage can have severe environmental consequences, cartridge seals offer reliable sealing solutions that enhance safety and environmental protection.

The chemical industry also heavily relies on cartridge seals to prevent hazardous fluid leakages. With the production of various chemicals, maintaining a safe and controlled operating environment is crucial, and cartridge seals provide an effective solution.

Other sectors, including wastewater treatment plants, power generation plants, and pharmaceutical manufacturing facilities, utilize cartridge seals for their sealing needs. Their versatility and adaptability make them suitable for diverse applications, while their contribution towards environmental compliance makes them an excellent choice for industries striving to achieve sustainable operations.

In conclusion, cartridge seals are essential devices that address environmental compliance and emissions control in various industrial applications. Their robust sealing capabilities, ease of installation, and maintenance-friendly design make them a preferred choice in industries aiming for sustainability. By preventing fluid leakage and reducing emissions, cartridge seals contribute to a cleaner and greener future, allowing industries to thrive while minimizing their environmental footprint.