Cartridge Mechanical Seals for Water and Wastewater Treatment Plants

Cartridge Mechanical Seals for Water and Wastewater Treatment Plants

Introduction:

Mechanical seals play a crucial role in preventing leakage and maintaining the integrity of rotating equipment in water and wastewater treatment plants. The demand for reliable and efficient seals has led to the development of cartridge mechanical seals, which offer numerous advantages over traditional packing seals. In this article, we will explore the benefits and applications of cartridge mechanical seals and how they contribute to the smooth operation of water and wastewater treatment plants.

1. The Importance of Mechanical Seals in Treatment Plants:

Water and wastewater treatment plants handle large volumes of fluids, often containing contaminants and chemicals. To ensure the safety and efficiency of these processes, it is vital to prevent any leakage of potentially harmful substances. Mechanical seals act as a barrier between the rotating shaft and the stationary housing of pumps and agitators, preventing any leakage and maintaining the desired pressure and flow rates. Without effective seals, treatment plants would face operational inefficiencies, environmental risks, and increased maintenance costs.

2. Understanding Cartridge Mechanical Seals:

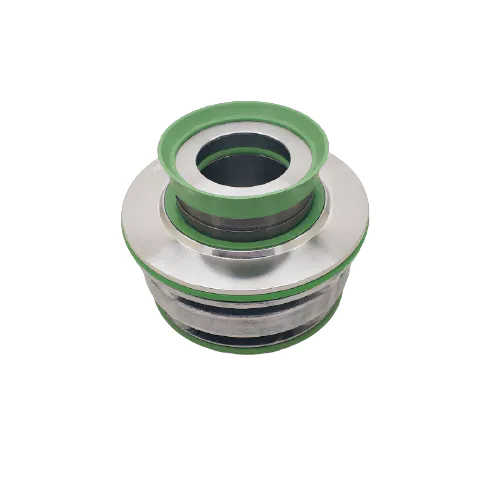

Cartridge mechanical seals are designed for ease of installation, operation, and maintenance. Unlike traditional packing seals, which need frequent adjustment and repacking, cartridge seals come pre-assembled in a self-contained unit. They consist of a rotating face, a stationary face, and a gland, all housed within a cartridge. This design simplifies the installation process, reduces downtime during seal replacement, and eliminates guesswork associated with seal adjustment.

3. Benefits of Cartridge Mechanical Seals:

3.1 Enhanced Seal Performance:

Cartridge mechanical seals offer superior sealing performance, ensuring a reliable and leak-free operation of pumps and agitators. The pre-assembled design eliminates any potential mistakes during installation and ensures precise alignment of the sealing faces. The use of high-quality materials in cartridge seals, such as advanced elastomers and hard faces, enhances their durability and ability to withstand harsh operating conditions.

3.2 Increased Efficiency:

The efficient design of cartridge mechanical seals reduces energy consumption and improves overall system efficiency. Their tight sealing capability minimizes leakage, thereby reducing fluid loss and preventing unnecessary energy expenditure. Moreover, the self-aligning feature of cartridge seals ensures optimal alignment between the rotating shaft and housing, resulting in reduced friction and wear, thus extending equipment lifespan.

3.3 Reduced Maintenance Costs:

With traditional packing seals, regular repacking and adjustment are required to maintain their performance. This process often involves significant downtime and labor costs. Cartridge mechanical seals, on the other hand, offer a 'fit and forget' solution, requiring minimal maintenance. Their self-contained design allows for easy replacement without any need for specialized tools or expertise. This ease of maintenance translates into reduced operational costs and increased productivity.

3.4 Versatility:

Cartridge mechanical seals are versatile and can be used in various applications within water and wastewater treatment plants. They are suitable for pumps, agitators, mixers, compressors, and other equipment involved in the treatment process. The wide range of seal options available ensures compatibility with different fluids, temperatures, and pressures, making cartridge seals adaptable to diverse plant requirements.

4. Applications in Water and Wastewater Treatment Plants:

4.1 Pumps:

Pumps are crucial components in water and wastewater treatment plants, tasked with transferring fluids between different stages of the treatment process. Cartridge mechanical seals provide reliable sealing in various pump types, including centrifugal, diaphragm, and submersible pumps. Their robust design ensures longevity, even in demanding applications involving corrosive or abrasive liquids.

4.2 Agitators and Mixers:

Agitators and mixers are essential for mixing chemicals and promoting the desired reactions within treatment facilities. Cartridge mechanical seals effectively seal the shafts of these rotating equipment, preventing any leakage that may lead to contamination or loss of chemicals. The self-aligning ability of cartridge seals ensures that the shaft remains centered, resulting in consistent performance and preventing premature failure.

4.3 Compressors:

Compressed air is widely used in water and wastewater treatment plants for various operations such as aeration, cleaning, and pneumatic control. Cartridge mechanical seals provide reliable sealing solutions in compressors, reducing air leakage and optimizing energy efficiency. Their ability to withstand high pressures and temperature variations makes them ideal for compressor applications.

4.4 Sludge Pumps:

Sludge pumps handle the transportation of thick, often abrasive, sludge generated during the treatment process. These challenging conditions require robust sealing solutions to prevent premature failure. Cartridge mechanical seals excel in sludge pump applications, providing effective sealing, reducing downtime, and minimizing maintenance needs.

4.5 Clarifiers and Thickeners:

Clarifiers and thickeners facilitate the removal of solid particles and impurities from the water and wastewater streams. The rotating components in these processes require efficient sealing to prevent the leakage of clarified liquid or sludge. Cartridge mechanical seals offer reliable sealing solutions for clarifiers and thickeners, ensuring the process operates smoothly and efficiently.

Conclusion:

Cartridge mechanical seals have revolutionized the sealing technology in water and wastewater treatment plants. Their ease of installation, superior sealing performance, increased efficiency, reduced maintenance costs, and versatile applications make them a reliable choice for critical equipment in treatment facilities. As these plants continue to handle increasing volumes of water and face stringent environmental regulations, the utilization of cartridge mechanical seals is expected to grow, ensuring effective sealing and minimizing risks associated with leakage.