Adhering to Industry Standards: Qualifying Blackmer Pump Seals for Specific Regulations

Introduction:

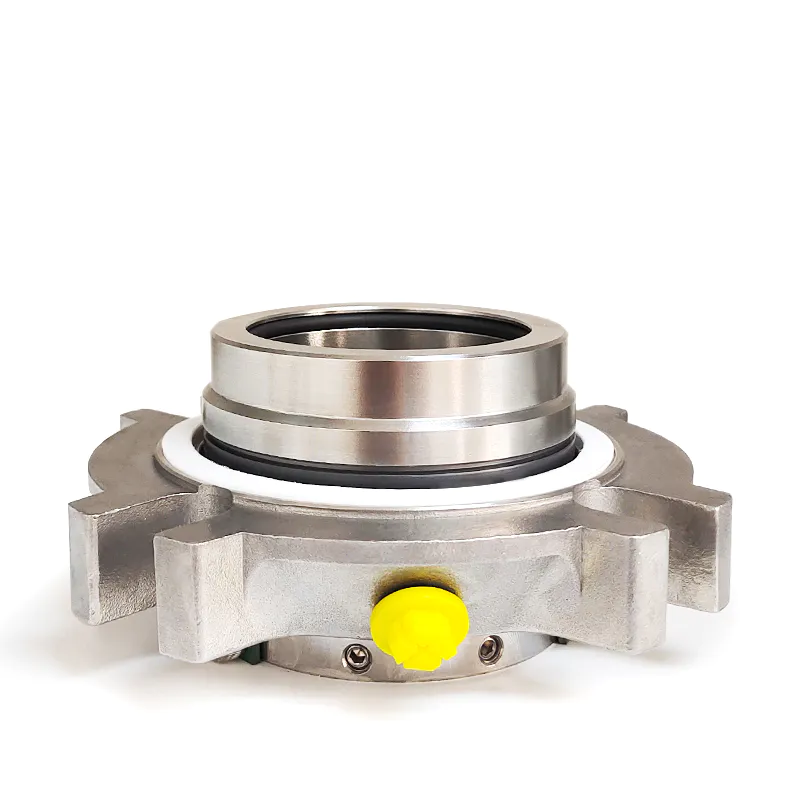

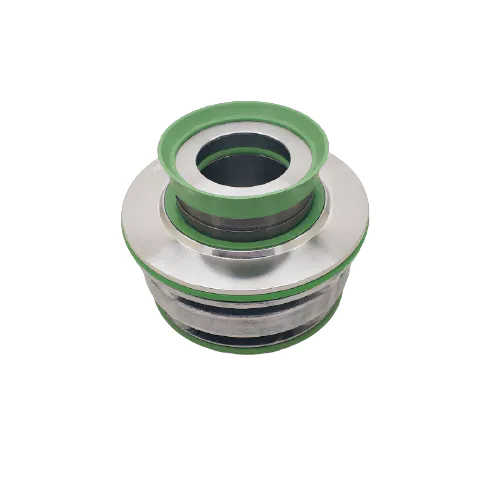

In the industrial sector, adhering to industry standards and regulations is crucial for ensuring the safety and efficiency of operations. One component that plays a significant role in numerous industries is the pump seal. These essential devices are responsible for preventing leakage and maintaining the integrity of pumps. However, not all pump seals are created equal, and they must undergo specific qualifications to comply with industry standards. This article will explore the qualifications of Blackmer pump seals, focusing on how they meet specific regulations to guarantee their efficiency and reliability in various industrial applications.

The Importance of Industry Standards in Pump Seals

Industry standards for pump seals are put in place to ensure the overall performance, safety, and compliance of these critical components. These standards are developed based on years of research, testing, and feedback from experts in the field. By adhering to industry standards, manufacturers can demonstrate the reliability and quality of their pump seals, providing customers with the confidence that their equipment will operate seamlessly.

By qualifying for specific regulations, Blackmer pump seals offer outstanding performance and reliability in a wide range of applications. These seals are designed to meet or exceed industry standards, ensuring that they can withstand demanding operating conditions while minimizing the risk of failure or leakage.

The Certifications of Blackmer Pump Seals

Blackmer, a leading manufacturer of positive displacement pumps, has a strong commitment to adhering to industry standards and regulations. As a result, their pump seals undergo rigorous testing and certifications to ensure they meet the highest quality standards. Some of the essential certifications that Blackmer pump seals hold include:

1. ISO 9001:2015 Certification

Blackmer pump seals are certified under ISO 9001:2015, a globally recognized standard for quality management systems. This certification emphasizes the company's dedication to consistently providing products that meet customer requirements and comply with regulatory standards. By adhering to ISO 9001:2015, Blackmer ensures the implementation of effective quality control processes, continuous improvements, and customer satisfaction.

The ISO 9001:2015 certification validates that Blackmer pump seals are manufactured using robust quality management systems, ensuring that they perform reliably and consistently in various industrial applications. This certification also reflects Blackmer's commitment to understanding and meeting customer needs, resulting in enhanced customer trust and satisfaction.

2. API 682 Compliance

API 682 is a widely accepted standard developed by the American Petroleum Institute (API) for mechanical seals used in centrifugal and rotary pumps in the oil, gas, and petrochemical industries. Blackmer pump seals comply with the stringent requirements outlined in API 682, guaranteeing their suitability for critical applications in these industries.

API 682 compliance ensures that Blackmer pump seals offer exceptional reliability, safety, and performance in harsh environments. The compliance includes specific requirements for materials, sealing systems, environmental control, and documentation. Blackmer pump seals meet these requirements, ensuring optimal performance, minimized emissions, and increased Mean Time Between Repair (MTBR).

3. ATEX Certification

For pump seals used in potentially explosive environments, ATEX certification is crucial. ATEX (Atmosphères Explosibles) is a European directive that sets the requirements for equipment and protective systems intended for use in explosive atmospheres. Blackmer pump seals are certified to be compliant with ATEX standards, ensuring their safety and suitability for use in explosive environments.

ATEX certification indicates that Blackmer pump seals meet the strict requirements for preventing ignition sources and minimizing the risk of explosions. These seals undergo rigorous testing to ensure their integrity and reliability under potentially hazardous conditions, providing users with the assurance of safe operations.

4. FDA Compliance

In industries such as food and beverage, pharmaceuticals, and cosmetics, pump seals must comply with strict regulations to ensure hygienic operations and prevent product contamination. Blackmer pump seals meet the requirements set by the U.S. Food and Drug Administration (FDA), guaranteeing their compliance with regulations applicable to these industries.

FDA compliance ensures that the materials and components used in Blackmer pump seals are safe for contact with food products, pharmaceuticals, and cosmetics. These seals are designed to prevent product contamination, adhere to rigorous sanitary standards, and withstand the demanding conditions of hygienic applications.

5. NSF/ANSI 61 Certification

For applications involving the transportation or treatment of drinking water, NSF/ANSI 61 certification is essential. Blackmer pump seals are certified to be compliant with NSF/ANSI 61, assuring their suitability for use in potable water systems. This certification guarantees that the materials used in these seals do not introduce harmful contaminants or affect the quality of the water being transported or treated.

NSF/ANSI 61 compliance ensures that Blackmer pump seals maintain the safety and integrity of drinking water systems. These seals undergo thorough testing to ensure they do not leach harmful substances and meet the strict guidelines set by regulatory bodies for water system components.

Summary

Adhering to industry standards is vital for ensuring the performance, safety, and compliance of pump seals. Blackmer pump seals undergo various certifications and qualifications to guarantee their reliability and suitability for specific regulations. The certifications, including ISO 9001:2015, API 682 compliance, ATEX certification, FDA compliance, and NSF/ANSI 61 certification, demonstrate Blackmer's commitment to delivering high-quality pump seals that meet the needs of diverse industrial applications.

With these qualifications, Blackmer pump seals offer dependable performance, reduced risk of leakage, and increased durability. By choosing Blackmer pump seals, industries can ensure the smooth operation of their equipment while adhering to the strictest industry standards and regulations.