What is a tandem dry gas seal?

by:Lepu Seal

2023-06-21

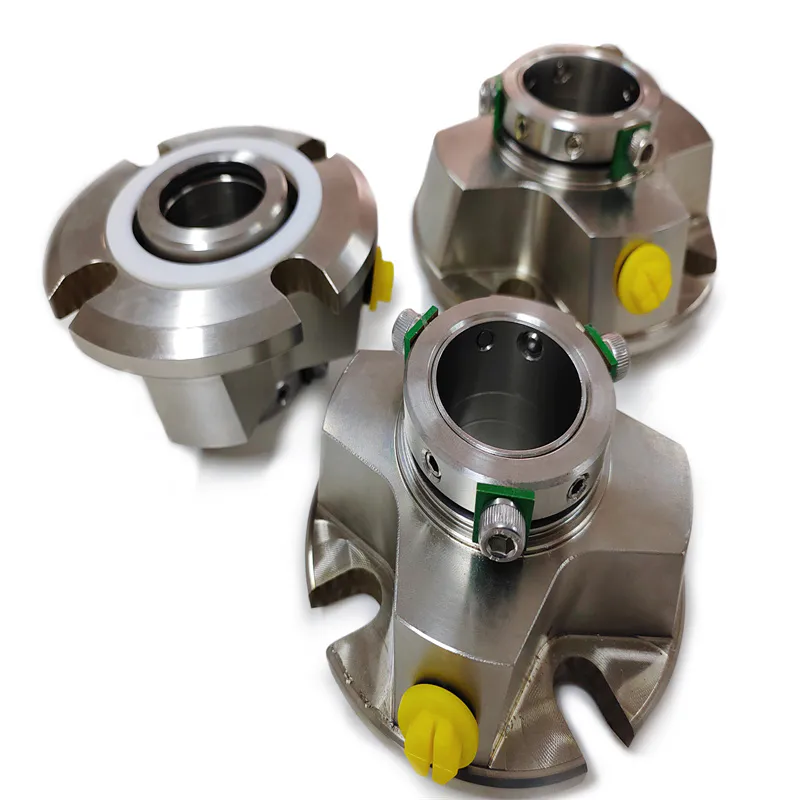

A tandem dry gas seal is a type of mechanical seal used to prevent leaks in compressors, pumps, and turbines. It consists of two stationary seals mounted back-to-back on the shaft sleeve and rotating rings that rotate with the shaft. The two seals work together to provide an effective barrier against leakage.

The primary purpose of a tandem dry gas seal is to prevent process gases from escaping into the atmosphere or surrounding environment. Instead, these gases are contained within the equipment where they can be safely processed further.

One significant advantage of using a tandem dry gas seal over other types of seals is that it eliminates any need for additional sealing systems like oil lubrication or cooling water. This makes it ideal for use in applications where process fluids are hazardous or difficult to handle.

Tandem dry gas seals also offer superior reliability and longevity compared to traditional wet seals as they operate without any contact between sealing surfaces. This means less wear and tear on components resulting in lower maintenance costs over time.

A tandem dry gas seal is an innovative solution designed to enhance industrial processes by preventing leaks while reducing maintenance costs and increasing overall efficiency.

How does a tandem dry gas seal work?

A tandem dry gas seal consists of two seals arranged in series, with a buffer gas injected between them. This design is engineered to prevent process gas leakage and ensure maximum reliability.

The primary seal, situated closest to the process fluid, acts as the main sealing element. It incorporates a rotating mating ring and a stationary face that are held together by mechanical force and hydrodynamic lift generated during operation.

As the equipment rotates, grooves within the seal create an aerodynamic lifting effect on the stationary face. This creates a thin layer of pressurized buffer gas between both surfaces, preventing contact or wear while also ensuring minimal leakage.

The secondary seal serves as a backup mechanism in case of any failure involving the primary seal. In such instances, it steps up to maintain reliable sealing function until maintenance can be conducted safely.

Monitoring systems continually check for pressure and temperature changes within this tandem arrangement. By doing so, operators can detect potential failures early on - safeguarding equipment integrity and minimizing downtime occurrences.

What are the benefits of a tandem dry gas seal?

Tandem dry gas seals offer a range of benefits that make them an attractive sealing option for various industries. They provide reliable and efficient sealing performance in high-speed applications, which is essential in industries such as oil and gas, chemical processing, and power generation.

Another benefit of tandem dry gas seals is their ability to handle extreme temperature ranges without any adverse effects on their performance. This means that they can operate efficiently even in extremely hot or cold environments without compromising the seal's integrity.

Additionally, tandem dry gas seals are designed to minimize leakage rates while maintaining optimal lubrication levels between the seal faces. This reduces the risk of equipment damage due to fluid contamination and prolongs the lifespan of machinery components.

These benefits make tandem dry gas seals a cost-effective solution for businesses looking to maintain reliable equipment operations while reducing maintenance costs over time.

What industries use tandem dry gas seals?

Tandem dry gas seals are widely used in various industries for their unique ability to control leakage and minimize environmental impact. One of the most significant industries that use tandem dry gas seals is the oil and gas industry, particularly within refineries and pipeline operations. These operations require high levels of safety, efficiency, and reliability to ensure maximum production with minimal downtime.

In addition to oil and gas, tandem dry gas seals are also common in power generation plants where they help regulate emissions by preventing leaks from turbines or compressors. The aerospace sector also uses these seals in aircraft engines as they provide an effective barrier against air contamination while reducing maintenance costs.

Furthermore, chemical processing plants rely on tandem dry gas seals due to their compatibility with a wide range of chemicals and gases used in the production process. The pharmaceutical industry has also adopted this technology for its ability to maintain sterile environments during drug manufacturing processes.

Any industry that requires efficient sealing solutions can benefit from using tandem dry gas seals. Their versatility makes them a popular choice across many sectors looking to improve performance while minimizing environmental damage caused by leaks or spills.

Tandem dry gas seal vs. other types of seals

When it comes to sealing rotating equipment, there are several types of seals available. One common type is the tandem dry gas seal.

Compared to other types of seals such as mechanical seals or oil-sealed glands, a tandem dry gas seal provides superior performance in terms of leakage control and reliability. This is because a tandem dry gas seal uses two sets of stationary and rotating rings that work together to maintain a tight barrier against any escaping fluids.

Mechanical seals require lubrication which can contaminate process materials if leaked, while oil-sealed glands have limitations when handling high pressure or temperature applications. Tandem dry gas seals overcome these challenges by using inert gases like nitrogen or helium for sealing instead of liquids.

Moreover, they can withstand harsh operating environments with temperatures ranging from -40掳C (-40掳F) up to 204掳C (400掳F). Furthermore, their ability to operate without contact between the rotating parts makes them less prone to wear and tear compared to other types of seals.

Compared with traditional mechanical and oil-sealed gland systems, a tandem dry gas seal offers several advantages in ensuring reliable sealing for varying industrial needs.

Conclusion

Tandem dry gas seals are an essential component for many industrial applications that require reliable and efficient sealing solutions. By using two sets of seal rings arranged in a tandem configuration, these seals can effectively prevent gas leakage and contamination while maintaining high levels of performance even under harsh operating conditions.

The benefits offered by tandem dry gas seals make them ideal for use in industries such as oil and gas, chemical processing, power generation, and more. With their ability to withstand extreme temperatures, pressures, and corrosive environments while minimizing maintenance needs and downtime costs.

The importance of selecting the right type of seal cannot be overstated when it comes to ensuring optimal equipment performance and safety. By choosing a high-quality tandem dry gas seal from a trusted manufacturer with expertise in sealing technology like Lepu Seal manufacturer can help ensure their operations remain both productive and profitable over the long term.

Custom message