What are the advantages and disadvantages of mechanical seals?

by:Lepu Seal

2022-08-07

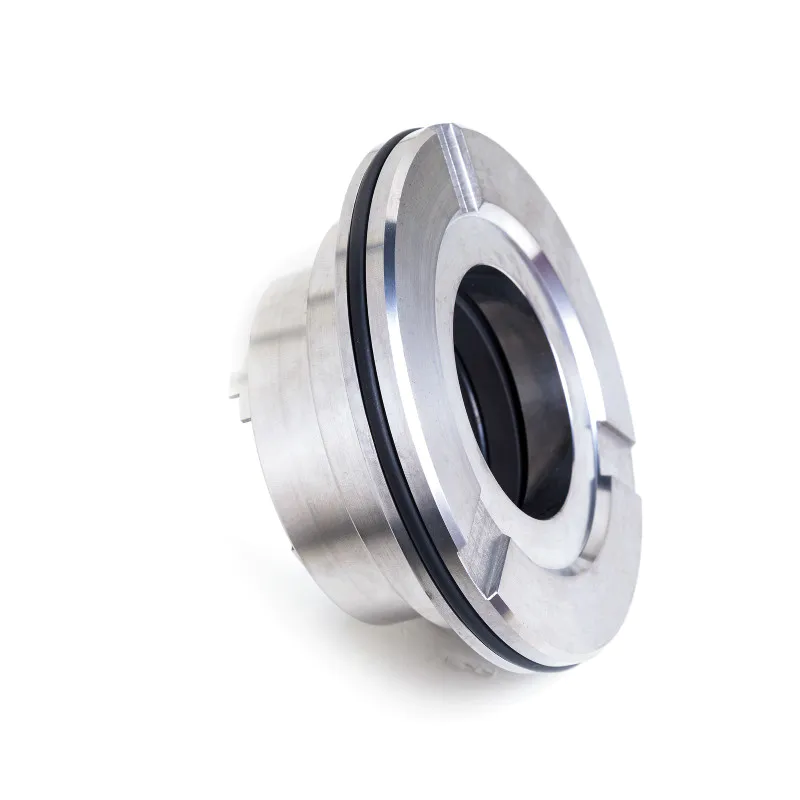

Mechanical seal is a widely used rotary shaft dynamic seal, referred to as mechanical seal, also known as face seal. Widely used in petroleum, chemical industry, light industry, metallurgy, machinery, aviation, and atomic energy, etc. What are the advantages and disadvantages of mechanical seals?

First, the advantages of mechanical seals:

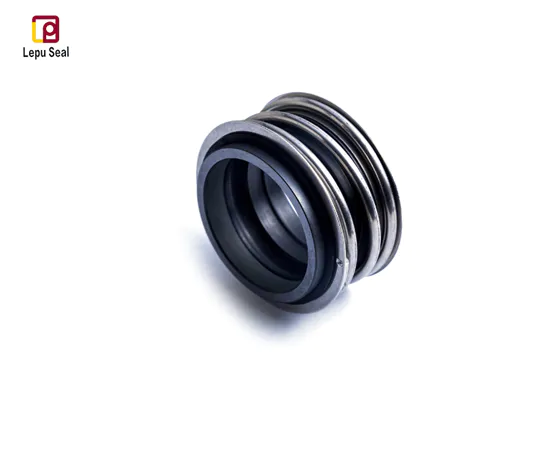

1. Good sealing. There are moving rings in the mechanical seal (weight point 2). The static sealing ring (micro-knitting point 3), the sealing end face (leak point 1), and the sealing parts between the end cover and the sealing cavity seal (shiguo point 4), Among them, the dynamic ring seal ring and the static ring seal ring are static seals, and generally have good sealing performance. The surface finish and flatness of the sealing end face are very high, generally in the state of boundary lubrication and semi-fluid lubrication, and the leakage is very small. The volume potential can also be limited to less than 0.01mL/h.

2. Long service life. The sealing end face of the mechanical seal is composed of materials with good white lubricity and wear resistance. Also has a wear compensation mechanism. Therefore, it can be used continuously for more than half a year, and it can be used for a year or even longer.

3. No need to adjust frequently. Under the action of sealing fluid pressure and elastic force, even after the friction pair is worn, the sealing end face will always automatically keep close. So once installed later. No need to adjust frequently. Easy to use. Suitable for continuous and automated production.

4. The frictional power consumption is small. The mechanical seal has a small contact area of u200bu200bthe dry friction pair and is in a semi-fluid lubrication or boundary lubrication state, and the friction power is generally only 20% to 30% of that of the packing seal.

5-axis bushings do not wear out. There is almost no relative movement between the shaft sleeve and the mechanical seal moving ring, which can be reused and reduce the cleaning consumption of parts.

6. Strong vibration resistance. Due to its buffer function, the machine city seal can still maintain good sealing performance when the equipment rotates within a certain range.

7. High sealing parameters and wide application range. Under the condition of reasonable selection of friction pair material, structure and appropriate auxiliary systems such as flushing and cooling, the mechanical seal can be widely used in various working conditions, especially in solving the problem of high temperature, low humidity, strong corrosion lock, high speed and other harsh working conditions. When sealed, it shows its superiority.

Second, the disadvantages of mechanical seals

1. The structure is complex and the assembly precision is high. Generally, the mechanical seal has a sealing end face composed of a pair of friction pairs. When the sealing parameters are high. It will consist of two pairs or pairs of friction pairs. With the auxiliary system, the structure is more complicated than the ordinary packing seal. At the same time, due to the high assembly precision requirements and certain technical requirements during installation, it is somewhat difficult for those who use mechanical seals for the first time.

2. It is inconvenient to replace. The mechanical seal parts are all annular parts, and these parts can not generally be made into a split type, so when replacing the seal parts, it is necessary to partially or completely disassemble the transmission part of the machine equipment to remove the seal parts from the drive shaft end.

3. It is inconvenient to troubleshoot. When the mechanical seal does not operate normally, it is difficult to take emergency measures. At this time, the equipment has to be stopped for processing.

4. Expensive. The mechanical seal has strict selection of materials, high processing and manufacturing precision, and long process route, so the cost is high. Compared with ordinary packing seals, the one-time investment is large.

Mechanical seal is a widely used rotary shaft dynamic seal, referred to as mechanical seal, also known as face seal. Widely used in petroleum, chemical industry, light industry, metallurgy, machinery, aviation, and atomic energy, etc.

Custom message