Structural features and types of mechanical seals

by:Lepu Seal

2022-09-09

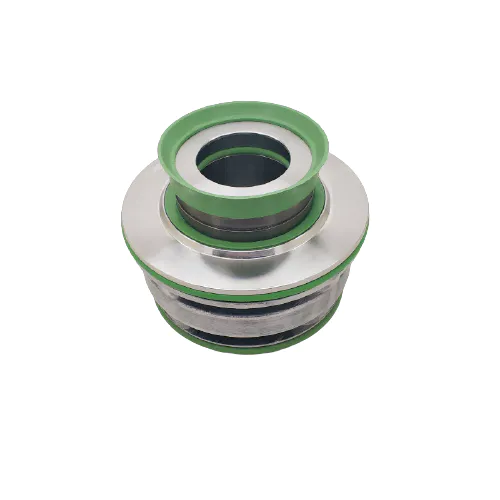

Structural features and types of mechanical seals

In order to adapt to the needs of different working conditions, there are many different types of mechanical seals: 1. According to the logarithm of the sealing end faces, it is divided into single end face, double end face and other mechanical seals. Single Face - Only one pair of sealing faces is required in a sealing device. It has a simple structure and is a commonly used mechanical seal type. Dual Faces - Two pairs of sealing faces in a sealing device. It has a complex structure and is suitable for the occasions of strong corrosion, flammable cartridge mechanical seal, explosive, toxic and harmful media and vacuum. 2. According to the pressure of the sealing fluid acting on the sealing end face, the Grundfos mechanical seal is unloaded or not, which can be divided into balanced and unbalanced mechanical seals. Balanced - the sealing fluid acts on the sealing end face and presses the mechanical sealing force of the inlet to partially unload or fully unload. Unbalanced - the pressure of the sealing fluid acting on the sealing end face is not unloaded. The balanced type is suitable for mechanical seals under medium and high pressure conditions; the unbalanced type is suitable for mechanical seals under low pressure conditions. 3. According to whether the spring is placed in the sealing fluid, it is divided into spring built-in type and spring external mechanical seal. Built-in spring - the spring is placed inside the sealing fluid. External spring - the spring is placed outside the sealing fluid. The sealing end face of the spring built-in type is in a good stress state, with small leakage and good cooling and lubrication. Therefore, in addition to corrosive media, the built-in structure should be used as much as possible. 4. According to the number of springs in the compensation structure, it is divided into single spring type and multi-spring type mechanical seals. Single spring type - only one spring in the compensation structure. It is used for light loads and small shaft diameters. Multiple Springs - There are multiple springs in the compensating tissue. For larger shaft diameters. The distribution of the spring force on the sealing end face is relatively uniform, but the diameter of the spring wire is small, and the corrosion has a great influence on the spring. 5. According to whether the compensation organization rotates with the shaft, it is divided into rotary type and stop type mechanical seal. Rotary - the compensation ring rotates with the shaft. Stop type - the compensation ring does not rotate with the shaft. The usual mechanical seals are often of rotary type, due to the simple structure of the compensation structure and the shaft, and the radial dimension is small. However, under high-speed conditions, the centrifugal force generated by the compensation ring and other rolling parts has a great influence, and the dynamic balance requirement is high, so it is more appropriate to use the stop type. From the perspective of structural characteristics, there are various types of mechanical seals, but in terms of structure, it mainly consists of the following four basic units: 1. The buffer compensation unit is a buffer compensation mechanism composed of a spring as the main component, which is to maintain the mechanical seal. Important conditions for normal operation. 2. The sealing unit is the sealing end face composed of the moving ring and the static ring, which is the core of the mechanical seal. 3. The auxiliary sealing unit is composed of the moving ring sealing ring and the static ring sealing ring. It is an auxiliary sealing structure to solve the parts other than the sealing end face that may leak, and is an indispensable component of the mechanical seal. Mechanical seal is a promising form of sealing in fluid sealing technology. Now it has reached the level of operating pressure of 40MPa, uniform sliding speed of the end face of 150m/s, and pv value of 200MPa•m/s. It can meet the requirements of most production process conditions. 4. The transmission unit is composed of a shaft sleeve, a key or a fixed pin. It is a reliable guarantee for completing the rotation of the moving ring with the shaft, and is also a prerequisite for completing the dynamic seal.

In order to adapt to the needs of different working conditions, there are many different types of mechanical seals: 1. According to the logarithm of the sealing end faces, it is divided into single end face, double end face and other mechanical seals. Single Face - Only one pair of sealing faces is required in a sealing device. It has a simple structure and is a commonly used mechanical seal type. Dual Faces - Two pairs of sealing faces in a sealing device. It has a complex structure and is suitable for the occasions of strong corrosion, flammable cartridge mechanical seal, explosive, toxic and harmful media and vacuum. 2. According to the pressure of the sealing fluid acting on the sealing end face, the Grundfos mechanical seal is unloaded or not, which can be divided into balanced and unbalanced mechanical seals. Balanced - the sealing fluid acts on the sealing end face and presses the mechanical sealing force of the inlet to partially unload or fully unload. Unbalanced - the pressure of the sealing fluid acting on the sealing end face is not unloaded. The balanced type is suitable for mechanical seals under medium and high pressure conditions; the unbalanced type is suitable for mechanical seals under low pressure conditions. 3. According to whether the spring is placed in the sealing fluid, it is divided into spring built-in type and spring external mechanical seal. Built-in spring - the spring is placed inside the sealing fluid. External spring - the spring is placed outside the sealing fluid. The sealing end face of the spring built-in type is in a good stress state, with small leakage and good cooling and lubrication. Therefore, in addition to corrosive media, the built-in structure should be used as much as possible. 4. According to the number of springs in the compensation structure, it is divided into single spring type and multi-spring type mechanical seals. Single spring type - only one spring in the compensation structure. It is used for light loads and small shaft diameters. Multiple Springs - There are multiple springs in the compensating tissue. For larger shaft diameters. The distribution of the spring force on the sealing end face is relatively uniform, but the diameter of the spring wire is small, and the corrosion has a great influence on the spring. 5. According to whether the compensation organization rotates with the shaft, it is divided into rotary type and stop type mechanical seal. Rotary - the compensation ring rotates with the shaft. Stop type - the compensation ring does not rotate with the shaft. The usual mechanical seals are often of rotary type, due to the simple structure of the compensation structure and the shaft, and the radial dimension is small. However, under high-speed conditions, the centrifugal force generated by the compensation ring and other rolling parts has a great influence, and the dynamic balance requirement is high, so it is more appropriate to use the stop type. From the perspective of structural characteristics, there are various types of mechanical seals, but in terms of structure, it mainly consists of the following four basic units: 1. The buffer compensation unit is a buffer compensation mechanism composed of a spring as the main component, which is to maintain the mechanical seal. Important conditions for normal operation. 2. The sealing unit is the sealing end face composed of the moving ring and the static ring, which is the core of the mechanical seal. 3. The auxiliary sealing unit is composed of the moving ring sealing ring and the static ring sealing ring. It is an auxiliary sealing structure to solve the parts other than the sealing end face that may leak, and is an indispensable component of the mechanical seal. Mechanical seal is a promising form of sealing in fluid sealing technology. Now it has reached the level of operating pressure of 40MPa, uniform sliding speed of the end face of 150m/s, and pv value of 200MPa•m/s. It can meet the requirements of most production process conditions. 4. The transmission unit is composed of a shaft sleeve, a key or a fixed pin. It is a reliable guarantee for completing the rotation of the moving ring with the shaft, and is also a prerequisite for completing the dynamic seal.

Custom message