Understanding the Importance of Grundfos Pump Seals in Industrial Applications

The Importance of Grundfos Pump Seals in Industrial Applications

Introduction:

In the world of industrial applications, efficiency and reliability are two crucial aspects that can make or break a business. When it comes to pumps, specifically Grundfos pumps, the seal is an integral part that ensures their smooth operation. Grundfos pump seals are designed to prevent leakage and maintain the efficiency of the pump, making them essential in various industries such as manufacturing, agriculture, and water treatment. In this article, we will delve into the importance of Grundfos pump seals in industrial applications, exploring their benefits and how they contribute to the overall performance of these pumps.

The Basics of Grundfos Pump Seals:

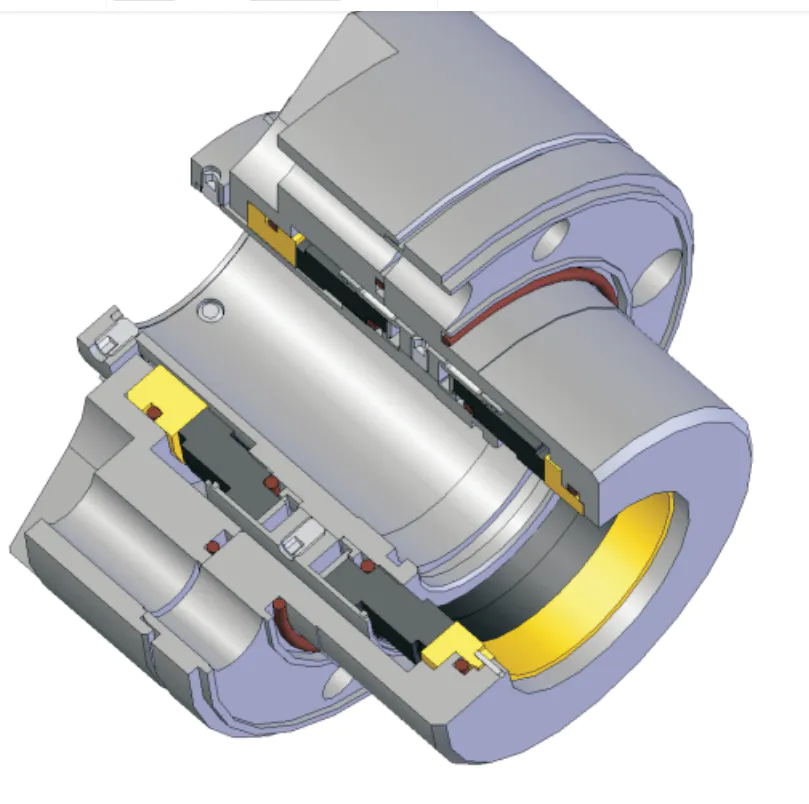

Grundfos pump seals are mechanical components that play a vital role in preventing leaks in pumps. These seals are located between the rotating shaft and the stationary pump housing and are responsible for sealing the fluid inside the pump, preventing any leakage to the atmosphere. Essentially, they act as a barrier to ensure that the pump operates efficiently and effectively.

There are different types of seals available for Grundfos pumps depending on the specific application and requirements. Some common types include mechanical seals, cartridge seals, and lip seals. Each type has its own unique design and features, but the ultimate goal remains the same – to provide a reliable and leak-free seal.

The Significance of Grundfos Pump Seals:

1. Preventing Leakage: Leakage is one of the primary concerns in any pumping system. It not only leads to a loss of valuable fluid but can also cause damage to the pump and surrounding equipment. Grundfos pump seals effectively prevent any leaks, ensuring that the pump operates optimally and avoids any costly downtime or repairs. By maintaining a tight seal, these seals significantly reduce the risk of leaks, providing peace of mind to industrial operators.

2. Enhancing Efficiency: Grundfos pump seals contribute towards enhancing the overall efficiency of the pump system. By preventing leakage, they ensure that the pump can maintain its desired flow rate and pressure, minimizing energy wastage. This improved efficiency results in reduced operational costs and increased profitability for businesses. Additionally, with efficient seal designs, friction and wear are minimized, extending the lifespan of the pumps and reducing maintenance requirements.

3. Ensuring Safe Operations: Safety is of utmost importance in any industrial setting. Grundfos pump seals play a crucial role in ensuring safe pump operations. With their reliable sealing capabilities, these seals prevent any hazardous substances or fluids from escaping into the environment, protecting workers and minimizing the risk of accidents or contamination. By investing in high-quality seals, industrial facilities can ensure compliance with safety regulations and maintain a secure working environment.

4. Compatibility and Versatility: Grundfos pump seals are designed to be compatible with a wide range of fluids and operating conditions. This versatility allows them to be used in diverse industrial applications, including chemical processing, pharmaceuticals, food and beverage, and wastewater treatment. Whether it is handling corrosive chemicals or abrasive materials, Grundfos pump seals can be tailored to meet specific requirements, making them a reliable choice for various industries.

5. Ease of Maintenance: Grundfos pump seals are designed with ease of maintenance in mind. They are readily accessible and can be easily replaced when required, minimizing downtime and ensuring smooth operation. With proper installation and regular inspection, routine maintenance of these seals becomes hassle-free. This ease of maintenance translates into cost savings and reduced downtime for industrial applications.

Summary:

In conclusion, Grundfos pump seals are indispensable in industrial settings where pumps play a vital role in the overall operation. These seals ensure leak-free pumping systems, enhance efficiency, promote safe operations, offer compatibility and versatility, and provide ease of maintenance. With their ability to prevent leakage and protect pumps from wear and tear, Grundfos pump seals contribute towards the smooth functioning of industrial applications across various sectors. Investing in high-quality seals not only ensures optimal performance but also translates into cost savings and increased profitability in the long run. So, whether you are managing a manufacturing facility or involved in water treatment processes, the importance of Grundfos pump seals cannot be understated.