The Versatility of Single Cartridge Mechanical Seals

The Versatility of Single Cartridge Mechanical Seals

Introduction:

Mechanical seals play a crucial role in preventing leakage and ensuring the efficient operation of rotating equipment such as pumps and compressors. Among the various types of mechanical seals available in the market, single cartridge mechanical seals have gained significant popularity in recent years due to their versatility and ease of installation. This article explores the versatility of single cartridge mechanical seals and their applications across different industries.

1. Understanding Single Cartridge Mechanical Seals:

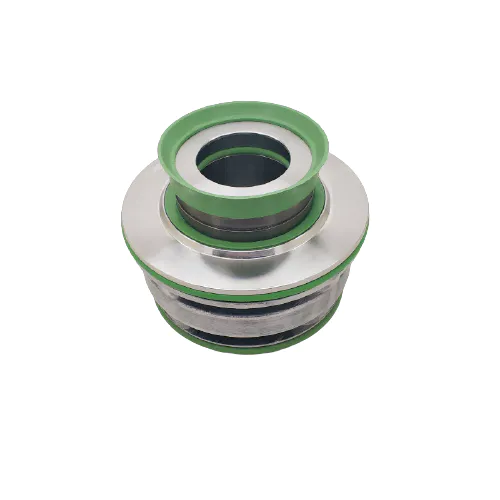

Single cartridge mechanical seals are self-contained units that consist of a rotating seal face, stationary seal face, and a gland plate, all housed in a cartridge. These seals are designed to fit into the stuffing box of pumps, eliminating the need for extensive equipment modifications. The cartridge design simplifies installation, reducing downtime during seal replacement and minimizing the risk of incorrect assembly.

2. Versatility in Pump Applications:

Single cartridge mechanical seals are widely used in various pump applications across industries. These seals provide excellent sealing performance in both low and high-pressure environments, making them suitable for a wide range of pumping systems. Whether it is a centrifugal pump in a water treatment plant or a chemical pump in a petrochemical facility, single cartridge mechanical seals offer reliable and durable sealing solutions.

3. Benefits in Aggressive Fluid Handling:

In industries where aggressive fluids such as acids, corrosive chemicals, or abrasive slurries are handled, single cartridge mechanical seals offer exceptional performance. The ability to select seal faces made from different materials, including those with high resistance to corrosion and wear, ensures compatibility with a wide variety of process fluids. This versatility allows single cartridge mechanical seals to maintain efficient sealing even in the harshest operating conditions.

4. Enhanced Energy Efficiency:

Maintaining process fluid integrity by eliminating leaks is critical in achieving energy-efficient operations. Single cartridge mechanical seals, with their advanced sealing technology, minimize leakages, resulting in energy savings. By reducing fluid loss, these seals not only improve overall equipment efficiency but also contribute to environmental sustainability by conserving valuable resources.

5. Adaptability to Varying Operating Conditions:

Single cartridge mechanical seals are designed to operate effectively across a wide range of temperatures, pressures, and speeds. Their adaptability enables their use in different operating environments, including extreme conditions. Whether it's a cryogenic application requiring low-temperature sealing or a high-speed pump handling volatile fluids, single cartridge mechanical seals provide reliable sealing performance under various challenging circumstances.

6. Seal Retrofit and Upgrading Possibilities:

One of the key advantages of single cartridge mechanical seals is their retrofitting capability. These seals can be easily installed in existing pumps without the need for significant modifications or equipment replacement. This feature is particularly beneficial for industrial plants looking to upgrade their sealing systems to improve reliability and reduce maintenance costs. Single cartridge mechanical seals offer a cost-effective solution for enhancing pump performance without major capital investments.

7. Maintenance and Serviceability:

Efficient maintenance and ease of serviceability are essential considerations in any sealing system. Single cartridge mechanical seals, being self-contained units, simplify maintenance procedures. With the ability to replace the entire cartridge during servicing, the risk of seal misalignment and contamination is minimized. This straightforward approach to maintenance ensures quick turnarounds, reducing downtime and optimizing equipment uptime.

Conclusion:

Single cartridge mechanical seals have emerged as versatile sealing solutions suitable for a wide range of applications. Their ability to adapt to varying operating conditions, retrofit existing equipment, and provide excellent sealing performance in aggressive environments has made them a popular choice across industries. With improved energy efficiency and simplified maintenance procedures, single cartridge mechanical seals offer a compelling value proposition for plant operators, contributing to overall operational reliability and cost optimization.