The Environmental Impact of Labyrinth Mechanical Seals: A Sustainability Perspective

Introduction:

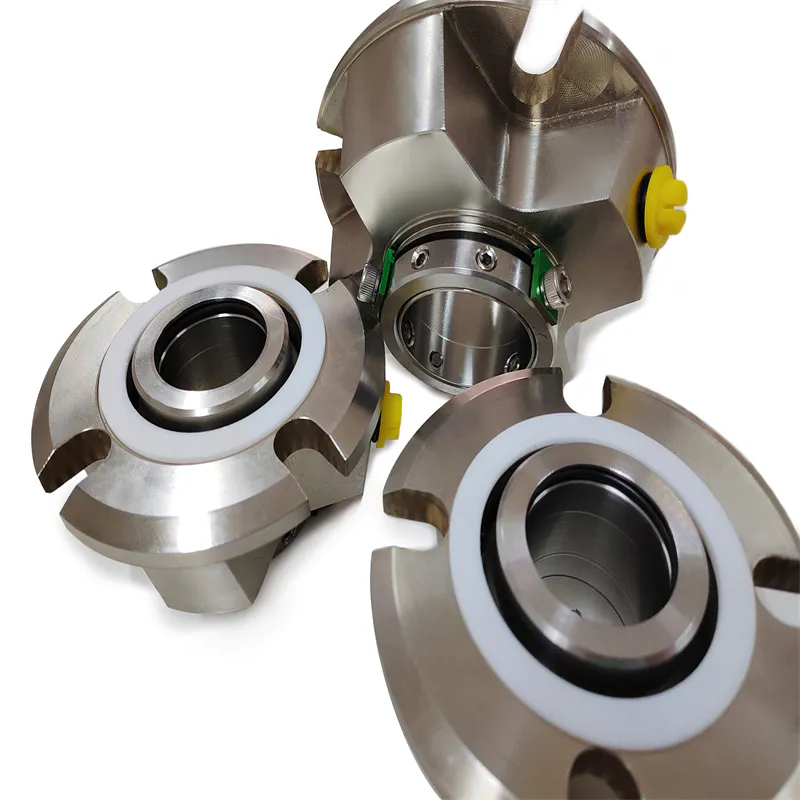

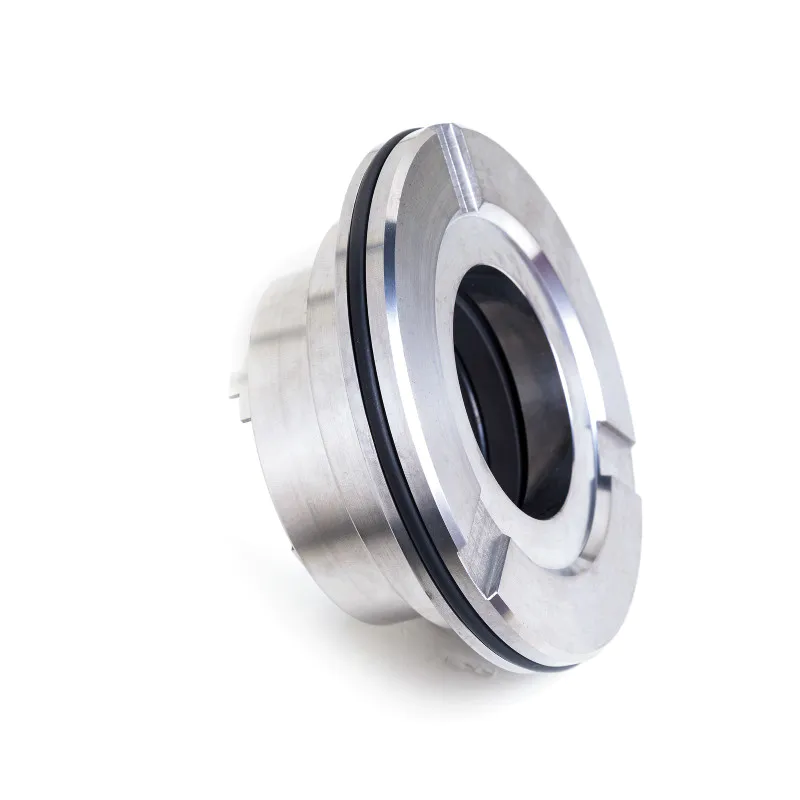

Mechanical seals play a crucial role in various industries, particularly in the sealing of rotating equipment. Labyrinth mechanical seals are known for their efficiency, reliability, and ability to prevent leakage. However, it is essential to assess their environmental impact from a sustainability perspective. This article delves into the environmental implications of labyrinth mechanical seals, highlighting their advantages, potential concerns, and sustainable practices that can mitigate any negative effects.

Advantages of Labyrinth Mechanical Seals:

Labyrinth mechanical seals offer several advantages that contribute to their widespread use in various industries. These advantages include:

1. Enhanced leakage prevention: Labyrinth seals are designed to provide exceptional sealing performance, minimizing the risks of leakage and ensuring operational efficiency. This characteristic is crucial in industries dealing with volatile or hazardous substances.

2. Increased equipment lifespan: By preventing the ingress of contaminants, labyrinth mechanical seals help extend the lifespan of rotating equipment. They effectively keep dust, moisture, and other external factors away from critical components, reducing wear and tear.

3. Reduced maintenance requirements: With labyrinth seals, maintenance needs are significantly reduced. Their robust design minimizes the need for regular maintenance, resulting in cost savings and increased operational uptime.

Environmental Concerns:

While labyrinth mechanical seals offer numerous benefits, it is essential to address their potential environmental concerns:

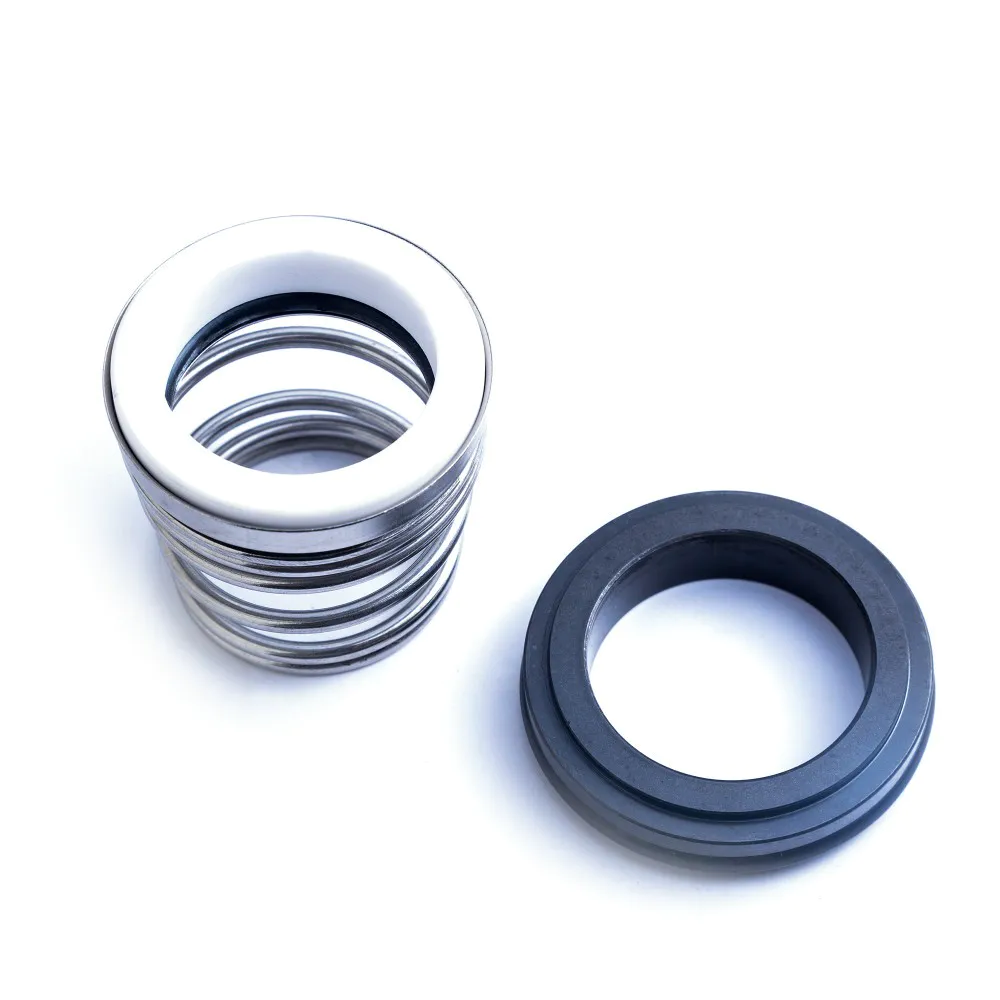

1. Material sourcing and manufacturing: The production process for labyrinth seals often requires the extraction of raw materials, some of which may have adverse environmental impacts, such as mining for metals. It is crucial that manufacturers prioritize sustainable sourcing practices and consider using recycled or eco-friendly materials whenever possible.

2. Energy consumption during operation: Labyrinth seals require energy to maintain their effective performance, particularly in high-pressure or high-temperature applications. While the energy consumption associated with these seals may be relatively low compared to other equipment, it is still important to optimize their design and operation for energy efficiency.

Sustainable Practices for Labyrinth Mechanical Seals:

To mitigate the potential environmental impacts of labyrinth mechanical seals, several sustainable practices can be adopted:

1. Material selection: Manufacturers can consider using eco-friendly materials, such as recycled metals or materials sourced from sustainable suppliers. Opting for materials with lower environmental footprints can significantly reduce the overall impact.

2. Energy-efficient design: By incorporating energy-efficient design features into labyrinth mechanical seals, such as reducing friction or optimizing sealing mechanisms, energy consumption can be minimized. This not only improves environmental sustainability but also reduces operational costs for end-users.

3. Improved sealing technologies: Continuous research and development efforts should focus on developing new and innovative sealing technologies that further minimize leakage and increase sealing efficiency. New materials and designs can contribute to sealing systems that are both reliable and sustainable.

4. Lifecycle assessment: Conducting a comprehensive lifecycle assessment of labyrinth mechanical seals helps identify potential environmental hotspots. By analyzing the product's overall impact from raw material extraction to disposal, manufacturers can make informed decisions to reduce any negative environmental consequences.

Conclusion:

Labyrinth mechanical seals offer significant advantages in terms of leakage prevention, equipment lifespan, and maintenance reduction. However, their environmental impact cannot be ignored. Manufacturers, users, and industry stakeholders must prioritize sustainable practices throughout the lifecycle of these seals, including material sourcing, manufacturing, and operation. By adopting sustainable approaches and continuously improving sealing technologies, labyrinth mechanical seals can contribute to a more environmentally friendly and sustainable future for various industries.