Single Spring Mechanical Seals: The Trustworthy Choice for Sealing

Single Spring Mechanical Seals: The Trustworthy Choice for Sealing

Introduction

Mechanical seals are essential components used in various industries to prevent leaks and ensure the efficient operation of pumps and rotating equipment. These seals play a crucial role in maintaining the integrity of a system by creating a barrier between the internal and external environments. Among the different types of mechanical seals available, single spring mechanical seals have emerged as a reliable and cost-effective choice for efficient sealing. In this article, we will explore the features, benefits, and applications of single spring mechanical seals.

1. The Functionality of Single Spring Mechanical Seals

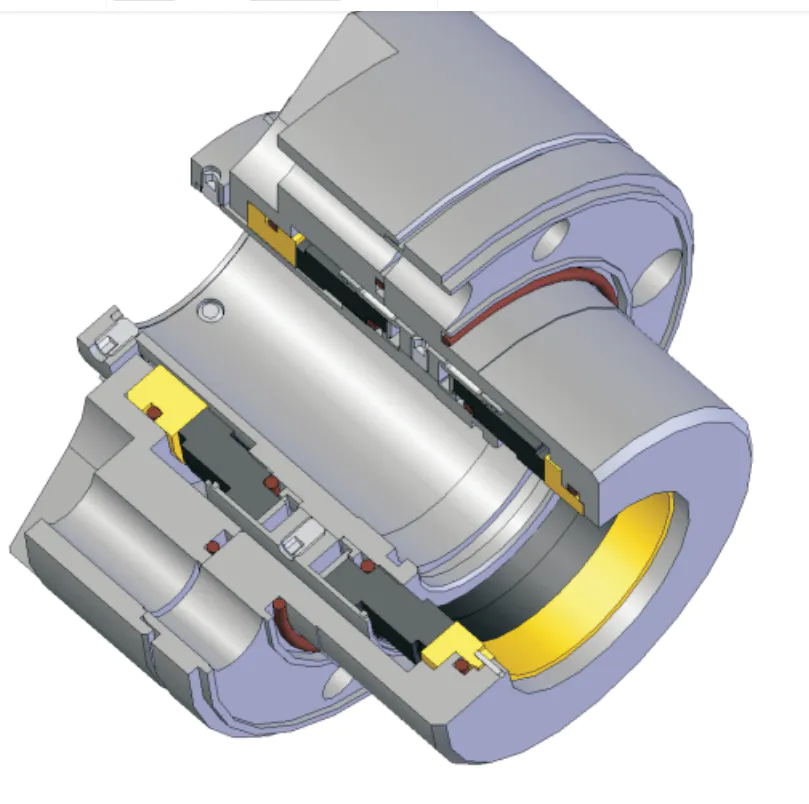

Single spring mechanical seals are designed to provide effective sealing under dynamic conditions. They consist of a rotating face and a stationary face, which are held against each other by a single spring. This spring enables the faces to maintain constant contact and adapt to various operating conditions, ensuring a secure seal. The design of these seals also incorporates secondary sealing elements, such as O-rings or elastomeric bellows, for enhanced leak prevention.

2. Key Features and Advantages

2.1 Simplified Construction: Single spring mechanical seals offer a simplified construction compared to more complex seal types. Their straightforward design with fewer parts makes them easy to install, operate, and maintain. Additionally, this simplicity reduces the chances of failure and ensures longevity.

2.2 Cost-effectiveness: The simplified construction of single spring mechanical seals translates into cost savings. These seals are generally more affordable compared to other mechanical seal options, making them an attractive choice for budget-conscious industries. Lower costs do not compromise their sealing efficiency, as single spring mechanical seals perform exceptionally well under a wide range of operating conditions.

2.3 Versatility: Single spring mechanical seals are compatible with a variety of liquids, including water, oils, hydrocarbons, and chemical agents. Their versatility allows them to be used across different industries, such as wastewater treatment, oil and gas, chemical processing, pharmaceuticals, and food and beverage.

2.4 Temperature and Pressure Resistance: Single spring mechanical seals are engineered to withstand high temperatures and pressures. They can perform reliably in extreme conditions, ensuring the integrity and safety of the sealed systems. This robustness makes them suitable for critical applications that demand resistance to heavy-duty operations.

2.5 Low Friction and Energy Consumption: The single spring design of these seals reduces friction between the faces, resulting in lower energy consumption. By decreasing power requirements, single spring mechanical seals contribute to energy efficiency and cost savings over the long term.

3. Applications of Single Spring Mechanical Seals

3.1 Water and Wastewater Treatment: Single spring mechanical seals are extensively used in water and wastewater treatment facilities, where they help prevent leaks in pumps and agitators. These seals maintain the efficiency of the treatment processes by ensuring the controlled flow of water and preventing contamination.

3.2 Oil and Gas Industry: In the oil and gas industry, mechanical seals are deployed in pumps and compressors to prevent leakage of hazardous substances. Single spring mechanical seals provide reliable sealing in pipelines, refineries, and other critical components, guaranteeing safe operation and preventing environmental damage.

3.3 Chemical Processing: Chemical plants handle corrosive and volatile substances, making sealing a critical concern. Single spring mechanical seals offer excellent resistance to a wide range of chemicals, making them suitable for pumps, mixers, reactors, and other equipment within the chemical processing industry.

3.4 Pharmaceutical Industry: Pharmaceutical manufacturing requires precise control of processes to avoid contamination and maintain product quality. Single spring mechanical seals ensure airtight sealing in various pharmaceutical applications, including mixers, agitators, and sterile processing equipment.

3.5 Food and Beverage Industry: Hygiene and product safety are paramount in the food and beverage industry. Single spring mechanical seals, with their compatibility with food-grade materials and effective sealing capabilities, play a vital role in ensuring the integrity of processing equipment and preventing any product contamination.

4. Installation and Maintenance Considerations

4.1 Proper Installation: To ensure optimal performance, it is crucial to follow the manufacturer's guidelines for installing single spring mechanical seals. Installation should be done carefully, ensuring proper alignment of the seal faces, correct torque values, and appropriate lubrication.

4.2 Routine Maintenance: Regular maintenance is essential to maximize the lifespan and efficiency of single spring mechanical seals. This includes periodic inspection, cleaning, and replacement of worn-out components. Adequate lubrication and monitoring of operating conditions can significantly enhance the longevity of these seals.

4.3 Failure Analysis: In the event of seal failure, conducting a proper failure analysis is crucial to identify the root cause. This analysis helps prevent future failures and optimize the selection and operation of single spring mechanical seals.

Conclusion

Single spring mechanical seals are a reliable and cost-effective choice for sealing applications across various industries. Their simplified construction, cost-effectiveness, versatility, temperature and pressure resistance, and low energy consumption make them the preferred choice for many sealing requirements. Whether it is water treatment, chemical processing, or the food and beverage industry, single spring mechanical seals provide the necessary sealing efficiency, ensuring the safe and efficient operation of systems. By selecting and maintaining these seals with care, industries can minimize leakage, enhance productivity, and reduce maintenance costs.