Single Spring Mechanical Seals: The Seal for Every Occasion

Single Spring Mechanical Seals: The Seal for Every Occasion

Introduction

The Importance of Mechanical Seals in Industrial Applications

Understanding Single Spring Mechanical Seals

The Advantages of Single Spring Mechanical Seals

Different Types of Single Spring Mechanical Seals

Applications of Single Spring Mechanical Seals

Installation and Maintenance of Single Spring Mechanical Seals

Conclusion

Introduction

Mechanical seals play a crucial role in ensuring the efficiency and reliability of various industrial processes. These seals are specifically designed to prevent leakage and contamination, making them an essential component in a wide range of applications. Among the various types of mechanical seals available, single spring mechanical seals have gained considerable popularity due to their versatility and effectiveness in sealing mechanisms. This article aims to explore the characteristics, advantages, and applications of single spring mechanical seals.

The Importance of Mechanical Seals in Industrial Applications

Mechanical seals are primarily used to prevent the leakage of fluids or gases in machinery, thus maintaining the integrity of the system. In industrial applications, where leaks can lead to significant losses and safety hazards, the role of mechanical seals becomes vital. By preventing leakage, these seals help eliminate machinery downtime, reduce maintenance costs, and ensure the safety of personnel.

Understanding Single Spring Mechanical Seals

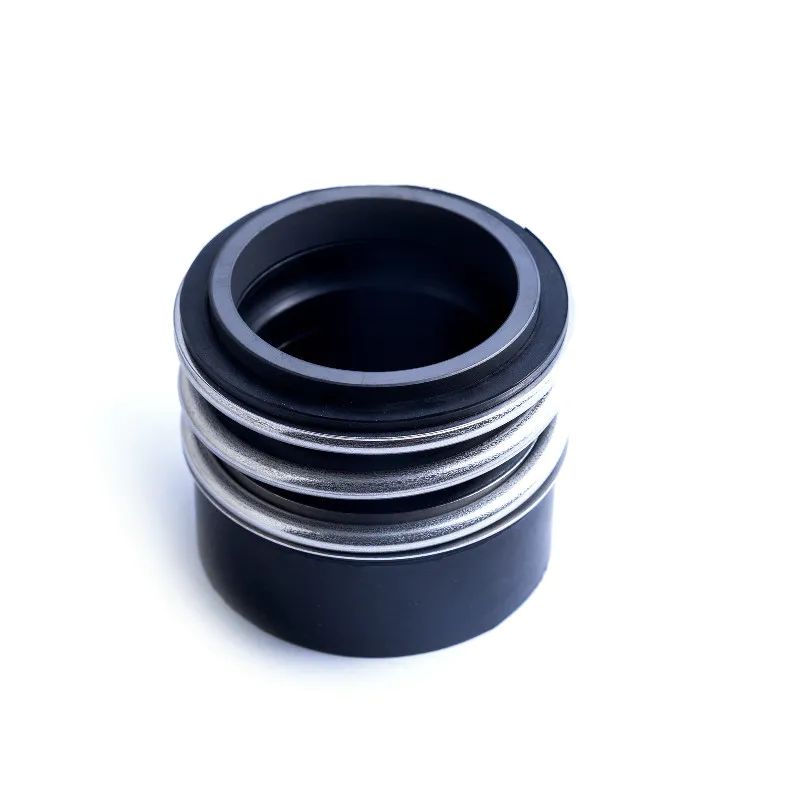

Single spring mechanical seals are designed with a single coil spring, which ensures constant pressure on the seal faces. This unique design allows the seal to adapt to various operating conditions, including temperature fluctuations, pressure differentials, and shaft movements. The seal faces of a single spring mechanical seal are typically made of high-quality materials, such as carbon or ceramic, ensuring excellent wear resistance and longevity.

The Advantages of Single Spring Mechanical Seals

1. Versatility: Single spring mechanical seals are versatile and can be used in a wide range of industrial applications, including pumps, mixers, and agitators. Their adaptability to different operating conditions makes them an ideal choice for various industries.

2. Cost-effectiveness: Single spring mechanical seals are cost-effective due to their simplified design and ease of installation. Their durability and longevity also contribute to reduced maintenance expenses and extended equipment lifespan.

3. Improved Seal Performance: Single spring mechanical seals provide reliable sealing performance, even in challenging environments. The constant spring pressure ensures a tight seal, minimizing the risk of leakage, while allowing for slight axial and radial movements of the shaft.

4. Reduced Friction and Heat Generation: The materials used in single spring mechanical seals are carefully selected to reduce friction and heat generation during operation. This feature prevents premature wear and extends the seal's lifespan.

5. Ease of Maintenance: Single spring mechanical seals are relatively easy to maintain, requiring minimal attention over an extended period. This reduces downtime and increases productivity, making them a favorable choice for industries that prioritize efficiency.

Different Types of Single Spring Mechanical Seals

1. Unbalanced Single Spring Mechanical Seals: These seals have a single coil spring that provides constant pressure on the seal faces. They are best suited for low-pressure applications with minimal temperature fluctuations.

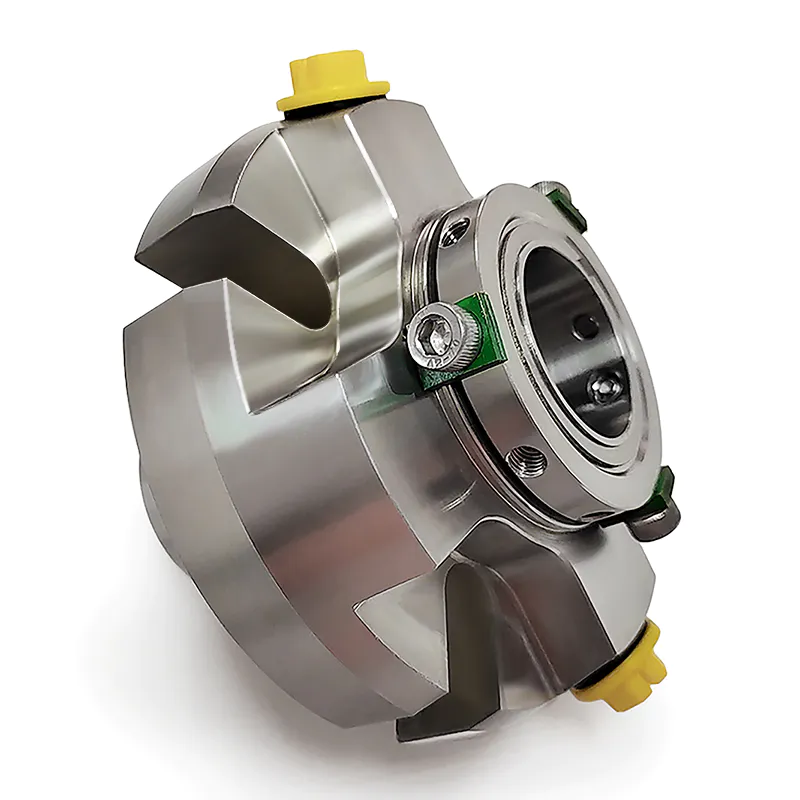

2. Balanced Single Spring Mechanical Seals: These seals are designed to handle high-pressure applications. They feature a secondary seal that balances the pressure on both sides of the seal faces, ensuring optimal performance even in challenging conditions.

3. Stationary Single Spring Mechanical Seals: As the name suggests, these seals have a stationary spring design, making them suitable for applications with high speed or axial movements.

4. Rotating Single Spring Mechanical Seals: These seals are designed specifically for rotating equipment, where the spring rotates with the shaft, ensuring continuous pressure on the seal faces.

Applications of Single Spring Mechanical Seals

Single spring mechanical seals find extensive use in various industries, including:

- Chemical processing: Specially designed single spring mechanical seals are used in pumps and mixers to prevent the leakage of hazardous chemicals.

- Food and beverage: These seals are utilized in pumps and agitators to maintain the hygiene and prevent contamination of food and beverage products.

- Oil and gas: Single spring mechanical seals are commonly used in pumps and compressors in the oil and gas industry to prevent leaks and ensure safety during transportation and processing.

- Pharmaceutical and healthcare: Single spring mechanical seals play a crucial role in preventing contamination and maintaining sterility in pharmaceutical manufacturing processes and healthcare facilities.

- Water and wastewater treatment: Single spring mechanical seals are employed in pumps and mixers to prevent water leaks and contamination, ensuring efficient water and wastewater treatment.

Installation and Maintenance of Single Spring Mechanical Seals

Proper installation and maintenance are essential to ensure optimal performance and longevity of single spring mechanical seals. Here are some key considerations:

- Ensure proper alignment and cleanliness of the equipment before installing the seal.

- Follow the manufacturer's instructions for seal installation, ensuring all components are correctly assembled.

- Regularly inspect the seal faces for signs of wear, pitting, or damage. Replace the seals when necessary to prevent leakage.

- Lubricate the seal faces as recommended by the manufacturer.

- Conduct routine maintenance, including cleaning and inspection, to identify any issues before they escalate.

Conclusion

Single spring mechanical seals offer a reliable and versatile sealing solution for various industrial applications. Their ability to adapt to different operating conditions, coupled with cost-effectiveness and ease of maintenance, makes them an excellent choice for industries seeking efficient and durable sealing solutions. By choosing the appropriate type and ensuring proper installation and maintenance, businesses can benefit from leak-free operations, reduced downtime, and enhanced safety.