Single Cartridge Mechanical Seals in LNG Facilities: Ensuring Gas Containment

Introduction to Single Cartridge Mechanical Seals in LNG Facilities

Liquified Natural Gas (LNG) facilities play a significant role in providing clean energy and meeting the increasing global demand for natural gas. With the growing importance of LNG, it becomes imperative to focus on the safety and efficiency of these facilities. Single cartridge mechanical seals have emerged as a crucial component in ensuring gas containment in LNG facilities. This article discusses the importance of single cartridge mechanical seals, their benefits, and their implementation in LNG facilities.

The Need for Gas Containment in LNG Facilities

LNG facilities handle large volumes of liquified natural gas, which is highly volatile and potentially hazardous if not contained properly. Ensuring gas containment is of utmost importance to prevent accidents and protect both the environment and the workforce. Single cartridge mechanical seals have proven to be a reliable solution for maintaining effective gas containment and preventing leakages in various industrial applications.

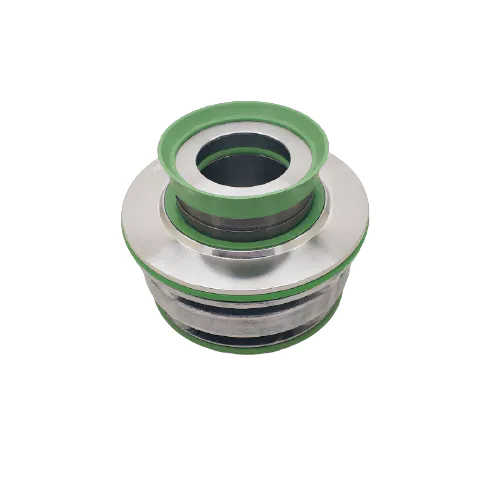

Understanding Single Cartridge Mechanical Seals

Single cartridge mechanical seals are composed of a rotating and stationary face pressed together to create a sealing mechanism. They are designed to fit into a single housing unit, simplifying installation and maintenance procedures. These seals are commonly made of materials such as carbon, silicon carbide, and ceramic, chosen for their durability and resistance to the harsh operating conditions found in LNG facilities.

Benefits of Single Cartridge Mechanical Seals in LNG Facilities

4.1 Enhanced Gas Containment: Single cartridge mechanical seals provide superior sealing capabilities, ensuring reliable containment of gases in LNG facilities. By effectively preventing leakages, they contribute to a safer working environment and reduce the risks associated with gas emissions.

4.2 Reduced Maintenance: The simplified design of single cartridge mechanical seals allows for swift and straightforward maintenance procedures. With their modular construction, these seals can be easily removed, inspected, and replaced, minimizing downtime and optimizing operational efficiency in LNG facilities.

4.3 Cost Efficiency: By minimizing leakages and reducing maintenance requirements, single cartridge mechanical seals offer significant cost savings. These seals enhance the lifespan of equipment and reduce the need for frequent replacements, resulting in improved overall profitability for LNG facilities.

4.4 Versatility: Single cartridge mechanical seals are compatible with various LNG facility equipment, including pumps, compressors, and agitators. Their versatile nature allows them to be utilized in different applications, supporting the smooth operation of the facility.

Implementation of Single Cartridge Mechanical Seals in LNG Facilities

Successful implementation of single cartridge mechanical seals in LNG facilities involves careful planning and adherence to industry standards. Here are some key considerations for their implementation:

5.1 Thorough Risk Analysis: Before implementing single cartridge mechanical seals, a comprehensive risk analysis should be conducted to identify potential hazards and ensure suitable measures are in place to mitigate them. This analysis should encompass factors such as pressure differentials, extreme temperatures, and chemical compatibility.

5.2 Proper Seal Selection: Choosing the appropriate single cartridge mechanical seal is crucial for its effective performance in an LNG facility. Factors such as gas type, pressure, temperature, and equipment specifications should be considered to select the seal with the right materials and design features to withstand the operating conditions.

5.3 Installation and Training: Proper installation and training of personnel involved in the operation and maintenance of single cartridge mechanical seals are vital for achieving optimal gas containment. Following the manufacturer's guidelines and providing adequate training ensure that the seals are installed correctly, reducing the risk of seal failure due to improper handling.

5.4 Regular Monitoring and Maintenance: Regular monitoring and maintenance of single cartridge mechanical seals ensure their long-term performance and gas containment capabilities. Periodic inspections, seal lubrication, and replacement of worn-out components should be carried out according to the manufacturer's recommendations and site-specific requirements.

In conclusion, single cartridge mechanical seals play a critical role in ensuring gas containment in LNG facilities. Their enhanced gas-tight capabilities, reduced maintenance requirements, cost efficiency, and versatility make them an ideal choice for sealing applications in the LNG industry. By implementing these seals following proper installation and maintenance procedures, LNG facilities can ensure safe and efficient operation while meeting the increasing global demand for natural gas.