PTFE Bellows Seals: The Ultimate Choice for Sealing Challenges

PTFE Bellows Seals: The Ultimate Choice for Sealing Challenges

Introduction:

Sealing is a critical aspect in various industries, ranging from manufacturing to pharmaceuticals. It ensures that no undesirable substances enter or exit a system, thereby maintaining the required operating conditions. To accomplish effective sealing, industries rely on advanced technologies and materials. PTFE (Polytetrafluoroethylene) bellows seals have emerged as the ultimate choice for tackling sealing challenges across industries. This article explores the versatility, benefits, applications, installation, and maintenance of PTFE bellows seals.

I. Understanding PTFE Bellows Seals

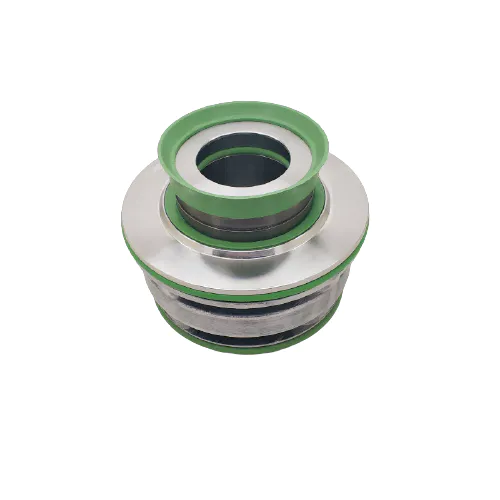

PTFE bellows seals are specialized sealing solutions designed to provide exceptional performance under demanding conditions. These seals are made from PTFE, a fluoropolymer known for its outstanding chemical resistance, low friction, and excellent thermal stability. PTFE bellows seals feature a flexible and corrugated structure that allows for dynamic movement while ensuring a tight seal.

II. Benefits of PTFE Bellows Seals

1. Chemical Resistance: PTFE is highly resistant to a wide range of chemicals, acids, and solvents, making it an ideal choice for industries dealing with corrosive substances. These seals prevent leaks and contamination, ensuring the integrity of the system.

2. Temperature Stability: PTFE bellows seals can withstand extreme temperatures, from cryogenic conditions to high heat applications. This attribute makes them suitable for industries operating in challenging environments, such as chemical processing, aerospace, and pharmaceuticals.

3. Low Friction: PTFE has one of the lowest coefficients of friction among all solid materials, minimizing wear and tear on the sealing surfaces. This low-friction characteristic enhances the longevity and effectiveness of PTFE bellows seals, making them a reliable choice for industries seeking durable sealing solutions.

4. Versatility: PTFE bellows seals can be custom-designed to fit various applications. They can accommodate axial, angular, and radial movement, making them suitable for pumps, compressors, mixers, and other dynamic systems. The adaptability of PTFE bellows seals ensures a secure and reliable sealing solution, regardless of the specific requirements of the application.

5. Low Maintenance: The self-lubricating properties of PTFE bellows seals significantly reduce the need for frequent maintenance. Their resistance to fouling and clogging ensures extended operational periods without premature failure or downtime, leading to increased productivity and cost savings for industries.

III. Applications of PTFE Bellows Seals

1. Chemical Industry: PTFE bellows seals find extensive applications in the chemical industry due to their excellent resistance to aggressive chemicals and solvents. They are widely used in pumps, reactors, agitators, and mixers, ensuring robust sealing performance and preventing leaks that could compromise safety and integrity.

2. Pharmaceutical Industry: The pharmaceutical industry demands strict sealing requirements to maintain sterile conditions and prevent cross-contamination. PTFE bellows seals are utilized in equipment such as pharmaceutical mixers, blenders, and reactors, ensuring reliable and contamination-free processes.

3. Food and Beverage Industry: PTFE bellows seals are FDA-approved and meet the stringent requirements of the food and beverage industry. They are commonly used in pumps, valves, and mixers, ensuring hygienic processes and preventing product contamination.

4. Oil and Gas Industry: The oil and gas sector operates in harsh environments with high pressures, temperatures, and aggressive chemical substances. PTFE bellows seals are capable of handling these demanding conditions, providing reliable sealing solutions in pumps, compressors, reactors, and valves.

5. Water Treatment Industry: PTFE bellows seals play a crucial role in the water treatment industry, where the prevention of leaks and contamination is essential. They are used in pumps, filters, reverse osmosis systems, and other equipment, ensuring efficient and reliable operations.

IV. Installation and Maintenance of PTFE Bellows Seals

1. Installation: Proper installation of PTFE bellows seals is vital to ensure effective sealing performance. It is essential to follow manufacturer guidelines and use appropriate tools for installation. Attention should be paid to proper alignment, torque, and pre-compression to prevent leakage.

2. Maintenance: PTFE bellows seals require minimal maintenance due to their self-lubricating properties. However, periodic inspections and preventive maintenance are recommended to ensure optimal performance. This may involve checking for wear, cleaning, and replacing seals when necessary, and evaluating sealing performance.

Conclusion:

PTFE bellows seals have earned their reputation as the ultimate choice for addressing sealing challenges across multiple industries. Their exceptional chemical resistance, temperature stability, low friction, versatility, and low maintenance requirements make them a reliable sealing solution. Whether in the chemical, pharmaceutical, food and beverage, oil and gas, or water treatment industry, PTFE bellows seals provide the necessary seal to safeguard system integrity, prevent leaks, and ensure efficient and reliable operations.